Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Manufactured By

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Advantages

- Excellent application properties for outstanding coverage and film build

- Superior storage stability with minimal syneresis

- Extremely good application properties, such as spatter and sag resistance

Applications & Uses

- Coating End Applications

- Application pH Range

- min. 8

- Use Level

- 0.1 - 0.8 %

- Application Information

- Bermocoll® EHM Extra can be used as a thickener in all types of latex paints, both in interior and exterior formulations.

- Bermocoll® EHM Extra improves high shear viscosity, roller spatter, flow and leveling.

- Bermocoll® EHM Extra offers enhanced color and heat stability, good color acceptance with minimal flocculation even when the most problematic colorants are used.

- Normal dosage is 0.1 to 0.8%, calculated on the total paint weight. In order to facilitate dispersion in water, Bermocoll® EHM Extra has been treated to give a pH-dependent dissolving.

- It should be added to neutral or slightly acid water.

- To speed up the dissolving process, pH should be increased to above 8 by using alkaline ingredients such as ammonia or alkaline pigment dispersants.

- If adjustment of the final paint viscosity is necessary, a highly concentrated slurry either in water or in an organic solvent should be used.

- It is not recommended to add the product as a dry powder after pigment grinding, due to the risk of lump formation at alkaline conditions.

Properties

- Appearance

- Off-white powder

- Characteristics

Value Units Test Method / Conditions pH Value (1% solution) 5 - 7 - - Solution Appearance Opaque - - Surface Activity Weak - - Viscosity (at 20°C, 1% solution) 250 - 450 mPa.s Brookfield LV - Specifications

Value Units Test Method / Conditions Particle Size (≤ 500 μm) 98 % - Salt Content max. 6 % - Water Content max. 4 % - - Note

Bermocoll® EHM Extra is a specialty hydrophobically modified methyl ethyl hydroxyethyl cellulose.

Technical Details & Test Data

- Technical Information

Bermocoll EHM Extra is specially developed to meet the demand for high-quality paint and next generation cellulose derivatives. It maintains all of the advantages of existing hydrophobically modified products, while boosting additional properties such as higher application (ICI) viscosity, color acceptance, reduced color float and enhanced storage stability

-

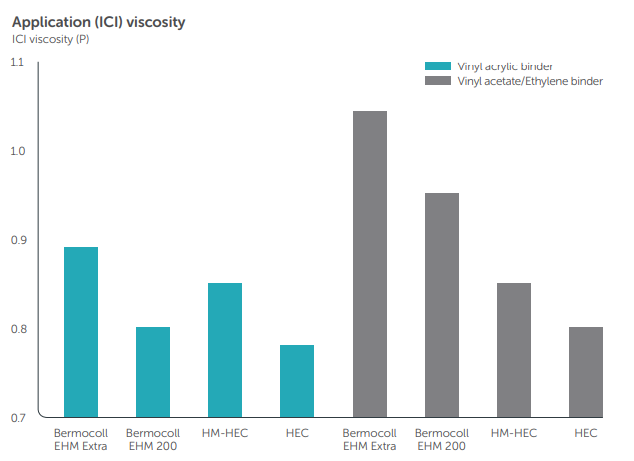

Paint rheology, higher ICI viscosity

With equal dosage and Stormer viscosity (KU), Bermocoll EHM Extra achieves higher ICI viscosity than competitor products – demonstrating the robust and reproducible thickening character of our product. The higher ICI viscosity contributes to an improved film build and thus better coverage.

-

Safety & Health

- Safety and Handling

At high temperatures and in contact with an open flame, Bermocoll® EHM Extra will burn slowly with the characteristics of cellulose

Packaging & Availability

- Country Availability

- Packaging and Transport

- Like many industrial processed powdery materials, cellulose ether dusts are combustible and can cause dust explosions.

- Dust formation must be avoided or kept to a minimum.

- Care should be taken to prevent ignition from heat, spark, open flames or hot surface.

- Bermocoll® EHM Extra is packed in polyethylene bags.

- Net weight 20 kg bags are available.

- We recommend emptying the bags from the bottom.

- The empty bags can be recycled or burned.

Storage & Handling

- Storage Information

- Unopened bags of Bermocoll® EHM Extra can be stored for several years in a cool, dry place.

- In opened bags, the moisture content of Bermocoll® EHM Extra will be influenced by the air humidity.

- At temperatures above 250 °C (480 °F), charring of Bermocoll® EHM Extra will occur.