Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Manufactured By

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Advantages

- Performance advantages

- Combines advantages of cellulose ethers with rheological properties of synthetic associative thickeners

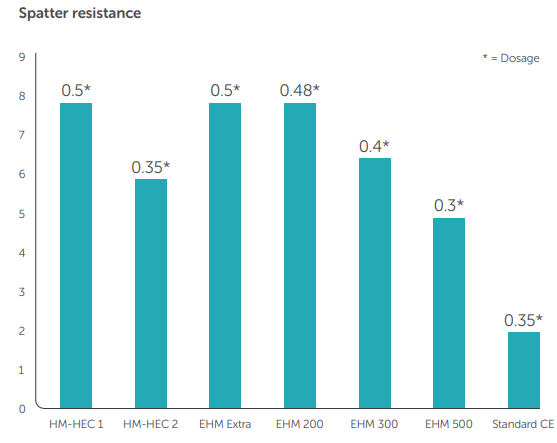

- Low spatter

- Good leveling

- Enhanced brushing viscosity

- Performance advantages

Applications & Uses

- Coating End Applications

- Use Level

- 0.3 - 0.5 %

- Application Information

- Bermocoll® EHM 300 is used as a thickener in all types of latex paints, intended for interior as well as for exterior use.

- Bermocoll® EHM 300 improves high shear viscosity, roller spatter, flow and levelling.

- Bermocoll® EHM 300 has a high resistance to enzymatic degradation.

- Normal dosage is 0.3 - 0.5 % calculated on the total paint weight.

- In order to facilitate dispersion in water, Bermocoll® EHM 300 has been treated to give a pH-dependent dissolving.

Properties

- Appearance

- Whitish powder

- Characteristics

Value Units Test Method / Conditions pH Value (1% solution) 5 - 7 - - Solution Appearance Opaque - - Surface Activity Weak - - Viscosity (at 20°C, 1% solution) 1700 - 3000 mPa.s Brookfield LV - Specifications

Value Units Test Method / Conditions Particle Size (≤ 500 μm) 98 % - Salt Content max. 4.5 % - Water Content max. 4 % - - Note

Bermocoll® EHM 300 is a hydrophobically modified ethyl hydroxyethyl cellulose.

Technical Details & Test Data

- Technical Information

Bermocoll® EHM is a non-ionic associative cellulose-based polymer with enhanced enzymatic resistance. We developed it in order to improve the rheological properties in latex paints. Bermocoll® EHM combines the performance of low viscosity cellulose with high thickening efficiency.

Safety & Health

- Safety and Handling

At high temperatures and in contact with an open flame, Bermocoll® EHM 300 will burn slowly with the characteristics of cellulose.

Packaging & Availability

- Country Availability

- Packaging and Transport

- Like many industrial processed powdery materials, cellulose ether dusts are combustible and can cause dust explosions.

- Dust formation must be avoided or kept to a minimum.

- Care should be taken to prevent ignition from heat, spark, open flames or hot surface.

- Bermocoll® EHM 300 is packed in in polyethylene bags. Net weight 20 kg.

- We recommend emptying the bags from the bottom.

- The empty bags can be recycled or burned.

Storage & Handling

- Storage Information

- In unopened bags, Bermocoll® EHM 300 can be stored for several years.

- In opened bags, the moisture content of Bermocoll® EHM 300 will be influenced by the air humidity.

- At temperatures above 250 °C (480 °F), charring of Bermocoll® EHM 300 will occur.