Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Manufactured By

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Industrial Additives Features

- Advantages

- Performance advantages

- Advanced color compatibility and rheology control to enhance touch up properties

- Optimal rheology profile

- Versatile

- Performance advantages

Applications & Uses

- Coating End Applications

- Application pH Range

- max. 7

- Use Level

- 0.2 - 0.7 %

- Application Information

- Bermocoll® Prime 1000 can be used as a rheology modifier in all types of latex paints.

- Bermocoll® Prime 1000 is recommended when high in-can as well as enhanced application viscosity is required.

- Bermocoll® Prime 1000 offers enhanced color and heat stability, and provides excellent color acceptance even with colorants that are known to be problematic.

- Normal dosage is 0.2 - 0.7 % calculated on the total paint weight.

- Bermocoll® Prime 1000 is easily dispersed in cold water of pH 7 or less.

- Bermocoll® Prime 1000 can form lumps when added to an alkaline liquid.

- To avoid this, it should be added as a ready stock solution, as slurry in slight acid water or in an organic solvent, or as a dry mix with other powder materials.

- The dissolving time after dispersion is influenced by the water pH.

- Alkaline additives can be used to speed up the dissolving process.

Properties

- Physical Form

- Appearance

- Whitish powder

- Dispersible in

- Cold Water

- Characteristics

Value Units Test Method / Conditions pH Value (0.5% solution) 5 - 7 - - Surface Activity Weak - - Viscosity (at 20°C, 1% solution) 500 - 900 mPa.s Brookfield LV - Specifications

Value Units Test Method / Conditions Particle Size (≤ 500 μm) 98 % - Salt Content max. 6 % - Water Content max. 4 % - - Note

Bermocoll® Prime 1000 is a low viscosity grade of methyl ethyl hydroxyethyl cellulose.

Technical Details & Test Data

- Technical Information

-

Superior color stability and excellent color development

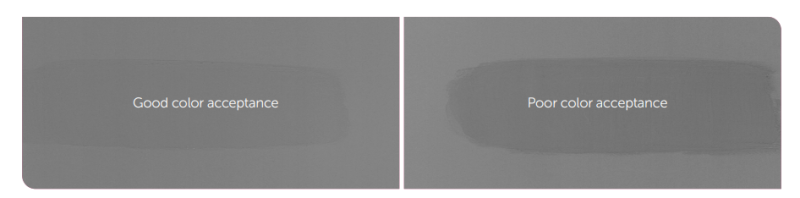

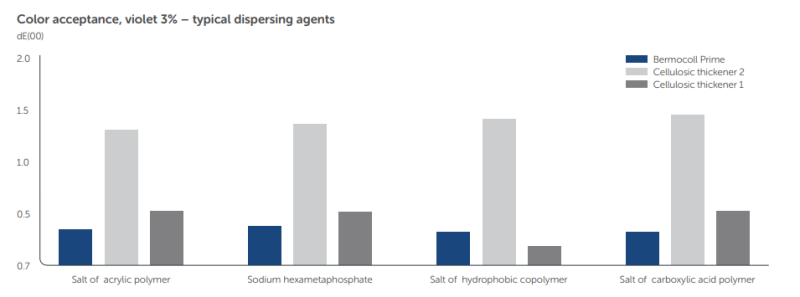

Excellent color stability is achieved with Bermocoll Prime within a wide range of colorants and latex binders. Bermocoll Prime is designed with particular attention to color acceptance and color development and offers reliable color performance. This means that the color appears in a uniform homogenous manner and at the expected color strength. Color acceptance is related to the compatibility, distribution and stability of the colorant in the base paint.

-

Efficient thickening and good stability at low addition rate

Paints formulated with Bermocoll Prime show very stable and constant viscosity even when stored at elevated temperatures and are very versatile with respect to compatibility with different kinds of binders.

Superior color stability and excellent color development

-

Flat paint formulation

Bermocoll Prime was tested in a system known to be sensitive with respect to color acceptance. The tinters used were of different color shades that are known to be problematic. A range of different dispersants were tested.

-

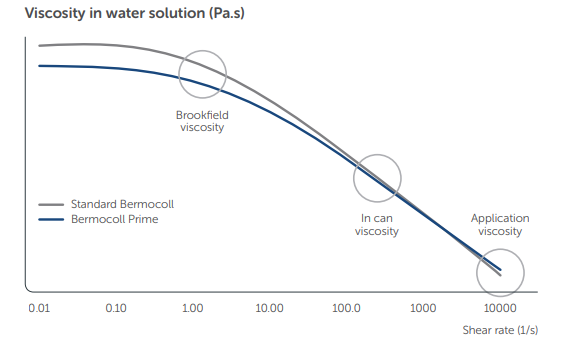

Optimal rheology profile

Bermocoll Prime is less shear thinning than Bermocoll Standard. With a comparable viscosity in paint Bermocoll Prime has lower Brookfield viscosity in water solution

-

Safety & Health

- Safety and Handling

At high temperatures and in contact with an open flame, Bermocoll® Prime 1000 will burn slowly with the characteristics of cellulose.

Packaging & Availability

- Country Availability

- Packaging and Transport

- Like many industrial processed powdery materials, cellulose ether dusts are combustible and can cause dust explosions.

- Dust formation must be avoided or kept to a minimum.

- Care should be taken to prevent ignition from heat, spark, open flames or hot surfaces.

- Bermocoll® Prime 1000 is packed in polyethylene plastic bags. Net weight 20 kg.

- We recommend emptying the bags from the bottom.

- The empty bags can be recycled or burned.

Storage & Handling

- Storage Information

- In unopened bags, Bermocoll® Prime 1000 can be stored for several years.

- In opened bags, the moisture content of Bermocoll® Prime 1000 will be influenced by the air humidity.

- At the temperatures above 250 °C (480 °F), charring of Bermocoll® Prime 1000 will occur.