Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Manufactured By

- Agrochemical Functions

- CASE Ingredients Functions

- Cleaning Ingredients Functions

- Industrial Additives Functions

- Molecular formula

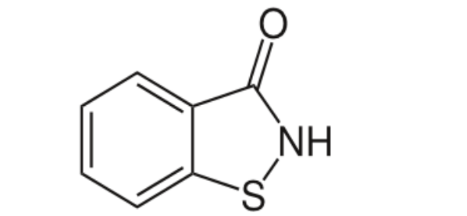

- C7H5NOS

- Technologies

- Product Families

- Chemical Structure

Features & Benefits

- Labeling Claims

- Product Benefits

- Formaldehyde free

- pH stable from 4 - 12

- Temperature stable up to 100°C

- FDA approved for various applications

- Broad spectrummicrobiocide, effectivelycontrolling bacteria, yeast,and fungi

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Adhesive & Sealant End Applications

- Coating End Applications

- Home Care Applications

- I&I Cleaning Applications

- Industrial Additives End Use

- Product Application

Bionix® BIT20W can be dosed directly either by open pouring or by metered pump. The concentration required to give protection depends on several factors. These include the susceptibility of the system to microbiological degradation, the extent to which microorganisms can gain access, the species involved, pH, temperature and length of time for which protection is required. Bionix® BIT20W is best added after any heating stage or when the product has cooled below 40oC..

PAPER MILLS:Paper coating compositions, Pulp, paper mills and paper mills process water systems.

Properties

- Physical Form

- Appearance

- Opaque

- Physical Properties

Value Units Test Method / Conditions Specific Gravity (at 20°C) 1.07 - - Boiling Point 100 °C - pH Value 6 - 8 - - Molecular Weight 151.18 - - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Viscosity (at 20°C) 700 - 1500 cPs - Percent Volatile 80 %V - Boiling Point min. 100.00 °C - Melting Point 0 °C - pH Value 6.0 - 8.0 - - Appearance Opaque - - Physical Form Liquid - - - CFR Clearances

21 CFR 175.105 Adhesives 21 CFR 176.170 As a preservative for paper coating compositions, at a level not to exceed 0.01 mg/in2 of finished paper or paperboard in contact with fatty and aqueous food.

21 CFR 176.180 As a preservative for paper coating compositions, at a level not to exceed 0.02 mg/in2 of finished paper or paperboard in contact with dry food.

21 CFR 176.300 Slimicides (max. 0.06lb product/ton dry wt. fiber)

21 CFR 177.2600 Uncured latex rubber

- General Preservatives

This product is used to reduce contamination in raw materials and/or products such as: natural and synthetic latices, emulsions paints and stains, oil-in-water emulsions, adhesives, inks and dyes, aqueous mineral slurries, pigment dispersions, photographic emulsions, building and constructions compositions, fresh animal hides and skins, leather processing solutions

- Oil/gas Production

Oil recovery systems, drilling fluids, packer fluids, completion fluids, subsurface injection waters, such as polymer and micellar/polymer waterfloods.

- Pesticide Formulations

For product preservation. For ultimate use-dilution protection. This product is exempt from tolerance under 40CFR180.920, materials exempted from the requirements of a tolerance when used in accordance with good agricultural practice as inert ingredients in pesticide formulations applied to growing crops only.

- Specialty Products and Household Products

Home cleaning products, floor cleaners, floor waxs and polishes, surface cleaners, window cleaners, dish detergents, liquid laundry detergents, fabric softeners, stain removers, car care products.

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Packaging & Availability

Storage & Handling

- Storage Information

- Keep container tightly closed in a dry and well-ventilated place. Avoid extreme temperatures. Do not expose to direct sunlight or ultraviolet light. Avoid strong oxidizing agents, mild steel, aluminum, copper and other materials. Protect from frost. If frozen, allow to thaw and stir well before use.

- Use personal protective equipment. Avoid breathing vapors, mist or gas. Ensure adequate ventilation. Evacuate personnel to safe areas. Wear respiratory protection.