Enhanced TDS

Identification & Functionality

- Carrier

- Chemical Family

- Chemical Name

- Manufactured By

- CASE Ingredients Functions

- Fluids & Lubricants Functions

- Industrial Additives Functions

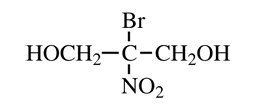

- Molecular formula

- C₃H₆O₄BrN

- Technologies

- Product Families

- Chemical Structure

Features & Benefits

- Industrial Additives Features

- Product Benefits

• Broad spectrum bacterial efficacy

• Controls Pseudomonas sp.

• Controls slime forming bacteria

• Controls anaerobic bacteria responsible for microbial induced corrosion

• Very effective in combination with other biocides.

Applications & Uses

- Applicable Processes

- Fluids & Lubricants Type

- Fluids & Lubricants End Use

- Industrial Additives End Use

- Product Application

Bionix® BP10 can be dosed directly either by open pouring or by metered pump, for cooling water applications open pouring is not permitted. The concentration required to give protection depends on several factors. These include the susceptibility of the system to microbiological degradation, the extent to which microorganisms can gain access, the species involved, pH, temperature and length of time for which protection is required. Bionix® BP10 can be used alone or in combination with other compatible biocides. The use of multiple preservatives provides additional protection against bacterial and fungal spoilage. The most popular combinations are those with 5-Chloro-2-methyl-4-isothiazolin-3-one and 2-methyl-4-isothiazolin- 3-one (CMIT/MIT). Bionix® BP10 is best added after any heating stage or when the product has cooled below 40°C.

Water Treatment

• Industrial recirculating water cooling towers and evaporative condensers, industrial and/or commercial air washer and/or air conditioning systems, industrial process water.

Pulp and Papermills

• Papermill process water, paper mill’s, bulk pulp.

General Perservative

• Adhesives, metalworking fluids, absorbent clays, paints, latex and other emulsion systems, hides and skins and leather.

Oil/Gas Production

• Oil and gas fluids, drilling muds, oil flooding waters/injection waters, injection fluids, enhanced oil recovery fluids, oil and gas pipeline and tank maintenance, water bottoms in oil or transportation tanks, well squeeze fluids, fracturing fluids, produced water.

Properties

- Physical Form

- Appearance

- Pale Yellow to Colorless

- Miscible in

- Water

- Physical Properties

Value Units Test Method / Conditions Specific Gravity (at 25°C) 1.06 - - Density 8.82 - - Freezing Point -15 °C - Boiling Point 266 °C - pH Value 4.05 - - Molecular Weight 199.99 - - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Appearance Colorless liquid - - Odor Characteristic Odor - - Melting Point 0 °C -

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Packaging & Availability

Storage & Handling

- Storage Information

• Keep container tightly closed in a dry and well-ventilated place. Avoid extreme temperatures. Do not expose to direct sunlight or ultraviolet light. Avoid sulfur containing rubber.

• Use personal protective equipment. Avoid breathing vapors, mist or gas. Ensure adequate ventilation. Evacuate personnel to safe areas. Wear respiratory protection.