Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Manufactured By

- CASE Ingredients Functions

- Fluids & Lubricants Functions

- Industrial Additives Functions

- Plastics & Elastomers Functions

- Molecular formula

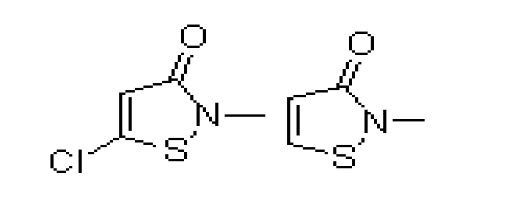

- C₄H₄ClNOS, C₅H₆CL₂N₂O₂

- Technologies

- Product Families

- Chemical Structure

Features & Benefits

- Labeling Claims

- Industrial Additives Features

- Product Benefits

• No VOC

• Effective use range pH 3 - 8

• Copper free stabilizer

• Aqueous solution readily incorporated into industrial formulations.

• Rapid inhibition of microbial growth and enzyme synthesis

• Formaldehyde free

• Biodegradable/non- persistent in the environment

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Fluids & Lubricants Type

- Adhesive & Sealant End Applications

- Coating End Applications

- Fluids & Lubricants End Use

- Industrial Additives End Use

- Product Application

Bionix® ISO2A can be dosed directly either by open pouring (not approved for cooling water treatment) or by metered pump either intermittently or on a continuous basis. Bionix® ISO2A is best added after any heating stage or when the product has cooled below 40°C. Care should be taken to ensure that the temperature and pH at the point of addition are suitable for the stability of the product.

Water treatment

• Air washers and industrial /recirculating cooling water towers, industrial recirculating closed loop water cooling systems, ultra filtration units and non-medical/no-potable reverse osmosis systems, brewery pasteurizers and can warmers.

Paper mills

• Paper mill slimicide. Typical addition points are the beaters, hydropulper or fan or broke storage pumps.

General preservative

• Paints and coating preservation, such as paper and wood coatings and paints used for architectural product finishes and special-purpose coatings, adhesive and tackifier preservation such as animal glues, vegetable glues, natural rubber, latices, polyvinyl acetate, stirene butadiene and acrylic latices, polymer latex preservation, including acrylic, stirene/butadiene, carboxylated styrene/butadiene, ethylene-vinyl acetate, biopolymers, zanthan gum, gum arabic, guar gum, protein-derived polymers, starches, casein derived polymers latices and solutions polymers, photoplate processing, fountain solutions and ink/ink components.

Oil/gas production

• Oilfield injection waters, enhanced recovery injection fluids, drilling, fracturing and completions fluids.

Properties

- Physical Form

- Soluble In

- Appearance

- Yellow-green liquid

- Physical Properties

Value Units Test Method / Conditions Soluble in Water - - Specific Gravity 1.27 - 1.33 - - Boiling Point 100 °C - pH Value 2.0 - 4.0 - - Molecular Weight MIT 115.1496 - - Molecular Weight CMIT 115.1496 - - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Odor Mild odor - - Vapor Pressure (Air) 23 mbar - Flash Point 200 °F ASTM D Closed Cup Boiling Point 212 °F - pH Value 2.0 - 4 - - Appearance Colorless to pale yellow liquid - - Physical Form Liquid - - Soluble in Water - - Specific Gravity (at 25°C, Water = 1) 1.015 - 1.035 - - - CFR Clearances

21 CFR 175.105 Adhesives 21 CFR 175.300 As an antimicrobial agent in emulsion-based silicon coatings at a level not to exceed 50 mg active ingredent/Kg in the coating formulation

21 CFR 175.320 As an antimicrobial agent in emulsion-based silicon coatings at a level not to exceed 50 mg active ingredient/Kg in the coating formulation

21 CFR 176.170 Cleared for use as antimicrobial agent for finished coatings and for additives used in the manufacture of paper and paperboard including fillers, binders, pigment slurries and sizing solutions not exceeding 25ppm active. Cleared for use as an antimicrobial agent for polymer latex emulsions in paper coatings not exceed ing 50ppm active in the coating formulation.

21 CFR 176.180 Cleared for use as antimicrobial agent for finished coatings and for additives used in the manufacture of paper and paperboard including fillers, binders, pigment slurries and sizing solutions not exceeding 25ppm active. Cleared for use as an antimicrobial agent for polymer latex emulsions in paper coatings not excced ing 50ppm active in the coating formulation.

Regulatory & Compliance

- Certifications & Compliance

Packaging & Availability

- Country Availability

- Packaging Type

- Packaging Information

Type Lbs Kg 55 gal. Drum 460 lbs 208 kg 275 gal. Tote 2,251 lbs 1021 kg