Enhanced TDS

Identification & Functionality

- Chemical Family

- Manufactured By

- Technologies

- Product Families

Applications & Uses

- Markets

- Applications

- Coating End Applications

- Use Level

- 30% additive (based upon the solid binder)

- Product Applications

Coatings Industry

Special Features and Benefits

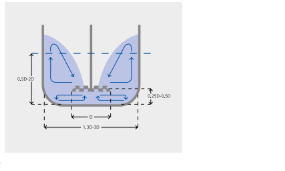

The additive improves the orientation of effect pigments (e.g. aluminum, mica) and enhances the flip-flop effect. Short wave defects (mottling, Bénard cells) are minimized and leveling of the subsequent clear coat layer is improved. Settling in the container is also reduced.

Recommended Use

CERAFAK 100 is recommended for solvent-borne base coats and one-coat metallic top coats in industrial coatings.

Recommended Levels

30% additive (as supplied) based upon the solid binder. The above recommended levels can be used for orientation. Optimal levels are determined through a series of laboratory tests.

Incorporation and Processing Instructions : The wax additive must be homogenized before use with a dissolver (4 m/s) and then added to the binder solution under agitation. In systems with CAB, the CAB solution must first be incorporated homogeneously in the binder solution at high shear forces (> 5 m/s) before the stirred wax additive, the effect pigment

slurry and the solvent can be added under agitation.

Properties

- Physical Form

- Typical Properties

Value Units Test Method / Conditions Viscosity (at 23°C) 13 mPa.s - Particle Size 25 μm Hegman Melting Point (Wax component) 105 °C - Xylene/butyl Acetate (as carrier) 1/1 - - Non Volatile Matter 10 % - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Appearance Dispersion liquid - - Kinematic Viscosity (at 40°C) 3 mm²/s - Dynamic Viscosity 13 mPa.s - Immiscible In Water - - Density (at 68°F) 0.9 g/cc - Lower Explosion Limit 1 %V - Flash Point 75 °F 49 (Pensky-Martens), Closed Cup Initial Boiling Point 266 °F - Odor Aromatic - - Upper Explosion Limits 8 %V - - Special Note

Special Note

Test method: Seeding

The wax additive is homogenized with a dissolver for 5 min at 4 m/s, then diluted with 20% n-butyl acetate and

stirred for a further 2 min at about 4 m/s. A draw down is then made on a glass panel with a 100 μm doctor blade.

The resulting film must be clear and free of seeds during drying.

Test method: particle size measurement with a grind-gage according to ISO 1524

The wax additive is homogenized with a dissolver for 5 min at 4 m/s. A draw down is then made on a 50 μm

grind-gage. Result: 25 μm particle size.- Composition

Ethylene vinyl acetate copolymer wax dispersion (EVA)

Regulatory & Compliance

- Chemical Inventories

Packaging & Availability

Storage & Handling

- Storage Information

Temperature sensitive. Do not store or transport above 35 °C. Stir before use.