Enhanced TDS

Identification & Functionality

- Chemical Family

- Manufactured By

- Industrial Additives Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

Applications & Uses

- Markets

- Applications

- Application Area

- Coating End Applications

- Use Level

- 50% (Coatings Industry)

- Application Information

Coatings Industry

Special Features and Benefits

The additive improves the orientation of effect pigments (e.g. aluminum, mica) and enhances the flip-flop effect. Short wave defects (mottling, Bénard cells) are minimized and leveling of the subsequent clear coat layer is improved. Settling in the container is also reduced.Recommended Use

Cerafak® 106 is recommended for solvent-borne base coats and one coat metallic top coats for automotive coatings.

Recommended Levels

50% additive (as supplied) based upon the solid binder.

The above recommended levels can be used for orientation. Optimal levels are determined through a series of laboratory tests.

Incorporation and Processing Instructions

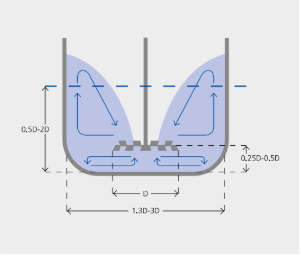

The wax additive must be homogenized before use with a dissolver (4 m/s) and then added to the binder solution under agitation. In systems with CAB, the CAB solution must first be incorporated homogeneously in the binder solution at high shear forces (> 5 m/s) before the stirred wax additive, the effect pigment slurry and the solvent can be added under agitation.

Properties

- Physical Form

- Typical Properties

Value Units Test Method / Conditions Non Volatile Matter 6 % - Viscosity (at 23°C) 10 mPa.s - Particle Size Distribution 20 μm Hegman Melting Point (Wax component) 105 °C - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Kinematic Viscosity (at 40°C) 7 mm²/s - Dynamic Viscosity 10 mPa.s - Density (at 20°C) 0.9 g/cc - Lower Explosion Limit 1 %V - Immiscible in Water - - Flash Point 24 °C 49 (Pensky-Martens), Closed Cup Initial Boiling Point 130 °C - pH Value Insoluble - - Odor Solvent-like - - Color White - - Appearance Dispersion - - Upper Explosion Limits 11 %V - - Note

Test method: Seeding

- The wax additive is homogenized with a dissolver for 5 min at 4 m/s, then diluted with 20% n-butyl acetate and stirred for a further 2 min at about 4 m/s. A draw down is then made on a glass panel with a 100 μm doctor blade. The resulting film must be clear and free of seeds during drying.

Test method: Particle Size Measurement with Grind-Gauge According to ISO 1524

- The wax additive is homogenized with a dissolver for 5 min at 4 m/s. A draw down is then made on a 50 μm grind-gauge. Result: 20 μm particle size.

- Composition

Ethylen-Vinylacetat-Copolymerwachsdispersion (EVA)

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

- OEM Specifications

Packaging & Availability

Storage & Handling

- Storage Conditions

Temperature sensitive. Do not store or transport above 35 °C. Stir before processing.