Enhanced TDS

Identification & Functionality

- INCI Name

- Manufactured By

- Cosmetic Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Benefit Claims

- Labeling Claims

- Product Benefits

- Naturally derived from renewable resource

- Durable hold

- Long lasting style

- Movable style with memory

- Flexible hold

- Fine, misty sprays

- Smooth, non-raspy feel

- Fast drying sprays

- Not sticky or tacky

- Curl definition

- Frizz control

Applications & Uses

- Markets

- Applications

- Application Format

- Hair Care Applications

- Use Level

- 1% - 10% (Styling aids such as creams, lotions, and pomades), 3% - 18% (Hair spray, depending on hold level)

- Recommended Applications

DynamX® styling polymer is for dynamic hairstyles. It has been developed to provide flexible, durable hold with memory performance from hairsprays, gels, mousses, lotions, pomades and other styling aids. In addition, DynamX® polymer imparts excellent curl definition and frizz control when used in styling formulations.

- Formulation Guidelines

Supplied as a liquid, DynamX® polymer is very simple to use. No heating is required and it goes into solution almost instantaneously. No neutralization is required as it is supplied fully neutralized. Shampoo removability can be optimized by formulating hairsprays at pH ≥ 8.75. Typical usage levels are 1-18%, on an as supplied basis.

Solubility

DynamX® polymer is supplied in hydroalcoholic solution and is, therefore, soluble in water and ethanol. It can be incorporated in both low and high (≤93%) VOC formulas.

Neutralization

DynamX® polymer is supplied fully neutralized with aminomethylpropanol, AMP-UltraTM PC 2000 grade. No additional neutralization is required.

Properties

- Soluble In

- Soluble in

- Water, Ethanol

- Typical Properties

Value Units Test Method / Conditions Volatile Organic Compound Content max. 93 % - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Oxidising Properties The substance or mixture is not classified as oxidizing. - - Explosive Properties Not Explosive - - Dynamic Viscosity max. 6,000 mPa.s - Auto Ignition Temperature min. 100 °C - Soluble In Water - - Bulk Density 979 kg/m³ - Density 0.938 g/cc - Relative Vapor Density (Air = 1) max. 1.6 - - Vapor Pressure (at 20°C) max. 53 hPa - Lower Explosion Limit (Ethanol) 3.3 %V - Explosion Limits (Upper, Ethanol) 19 %V - Self-Ignition 363 °C - Flammability (Liquids) Flammable liquid and vapor. - - Evaporation Rate max. 1.7 - - Flash Point 29 °C Pensky-Martens Closed Cup Boiling Point 78 °C - Melting Point -20 - 0 °C - pH Value 8.3 - 9.2 - - Odor Slight - - Appearance White powder - - - Compatibility

DynamX® polymer can be blended with other of our resins to tailor a formulation to your needs. It is compatible with acrylate (including the Amphomer®, Balance® polymer series) and acetate (Resyn® 28-2930) polymers. Polymer blend ratios can be controlled in order to optimize stiffness and high humidity curl retention without negatively affecting style memory. Although memory effects are optimized from hairspray systems, DynamX® polymer can be beneficial in gel and mousse applications. For use in gels, it is compatible with the following thickeners:

Rheology modifier Control Carbopol ETD 2020 Hazy; good hand clarity

Structure® 2001 Very slightly hazy; excellent hand clarity

Hydroxyethylcellulose Clear Xanthan Gum Very slightly hazy; excellent hand clarity

DynamX® polymer has been successfully formulated into prototype mousse formulations. Although it is anionic, it is compatible with small amounts of conditioning polymers, such as Polyquaternium-4 and Polyquaternium-11. It has also been found to be compatible with other ingredients common to styling products such as isopropanol, acetone, dimethylether, hydrocarbon and hydrofluorocarbon propellants, silicones, proteins, botanicals and UV absorbers.

Technical Details & Test Data

- Performance Properties

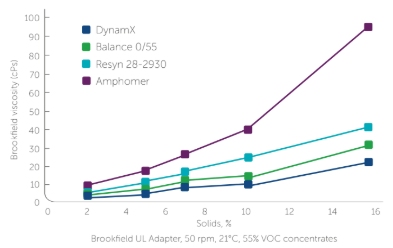

Viscosity Profile

DynamX® polymer changes the rules of hairstyling in a number of ways. To begin, hairsprays formulated with DynamX® polymer give a very small spray particle size, which allows for quick drying time from low VOC systems. The very low polymer solution viscosity provides good sprayability no matter what the VOC level of the formulation. And, it maintains a low viscosity at higher concentrations, which allows the formula to flow along the hair to efficiently form spot welds at the hair fiber junctures.

When hairspray is dispensed, the volatile solvent evaporates and the hairspray’s solids level increases as it travels to, and flows along the hair. Due to its inherent low viscosity, DynamX® hairsprays show a less dramatic increase in viscosity after dispensing compared to other resins. This allows the hairspray droplets to efficiently migrate down the hair to form spot welds at the hair fiber junctures.

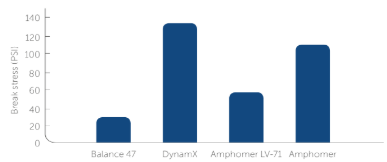

Molecular weight vs film toughness

Another game-changing attribute of DynamX polymer is the relationship between its molecular weight and film toughness. Film toughness is related to the integrity of the film. Tough films have elasticity, strength and require a high level of energy to break. Polymer films that are tough are more capable of withstanding the stresses typically experienced throughout the day (i.e. touch, movement) without an adverse effect on the style shape retention. Traditionally, as the molecular weight of a polymer increases, so does its film toughness.

Using a Sintech tensile tester, the stress required to break the polymer film can be measured.

Interestingly, as shown below, DynamX® polymer has a molecular weight of approximately 40,000 daltons, yet its film toughness is greater than other acrylate-type polymers of higher molecular weight. The polyurethane/acrylate technology of DynamX® polymer has been designed to optimize film toughness and breaks the toughness/molecular weight relationships of traditional styling polymers.

DynamX® polymer breaks the molecular weight trend, demonstrating a film toughness that is triple the level expected for a corresponding all-acrylate polymer.

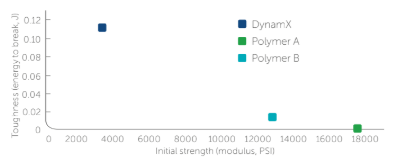

The evaluation of polymer films gives a good indication of the on-hair performance properties the polymer will give. For instance, polymer films that have a high initial strength, using traditional technologies, tend to provide a stiff, strong hold on the hair. Other conventional technologies give films with a low initial strength and thus a flexible hold, which traditionally have been weak.

In addition to the initial strength, the energy required to break the film further defines the performance. Films that are difficult to break are more capable of withstanding stress (i.e., touch, wind) and retaining the hairstyle.

Polymer film modulus vs energy to break

To better understand the film properties of DynamX® polymer and those of competitive polymers, a Sintech tensile unit was used to measure the modulus (initial strength) and the energy required to break the films (film toughness).

As seen in the next graph, the film properties of DynamX® polymer are unique in comparison to those of competitive polymers. Polymers A and B have high initial film strengths, yet very low energy is required to break their films. They are strong initially (stiff feel), but they are brittle and break easily.

The DynamX polymer film properties are nearly opposite in nature. It has a lower initial strength and requires a very high level of energy to break. It is elastomeric in nature, as it is easily transformed, but the film will actually stretch to a great degree before finally breaking.

The low modulus and high degree of toughness of DynamX® polymer films provides styling products with flexible, durable hold properties. Hairstyles can move naturally, without losing their shape.

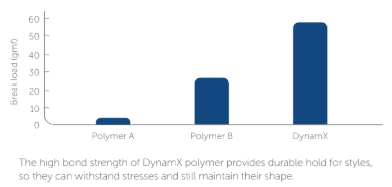

Adhesion to hair bond strength analysis

Another way DynamX® polymer changes the rules is through its adhesive properties. The adhesive film properties can be evaluated using a Diastron MTT, by measuring the force required to break a polymer spot weld between two hair fibers. The force required to break that weld is the bond strength.

Below shows that Polymer A has very low bond strength, indicating that the network of welds within a hairstyle will be easily broken, and the style will lose its shape. Polymer B has higher bond strength, offering better style retention than Polymer A.

The DynamX polymer bond strength is superior to all, as a great amount of force is required to break the spot weld. This confirms earlier results showing DynamX polymer provides a long lasting, durable hold.

The high bond strength of DynamX polymer provides durable hold for styles, so they can withstand stresses and still maintain their shape.

Dynamic curl memory

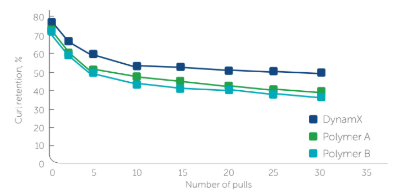

Film evaluations provide a good basis for understanding the benefits that will be experienced by the consumers. Hair tress evaluations offer the next level of knowledge, however. To better understand the memory benefit to a bundle of hair, the Dynamic Curl Memory test was developed. Using a curling iron, 10 inch tresses are rolled into curls, then sprayed with product and allowed to dry. Once equilibrated, the hair tresses are hung on retention boards and an initial curl length measurement is made. The tresses are then mechanically extended. This pulling motion is completed 30 times, with length measurements made at pulls 5, 10, 15, 20, 25 and 30.

The curl retention is then calculated in terms of percentage. The graph below shows the results of the Dynamic Curl Memory test, with DynamX polymer exhibiting significantly superior curl memory compared to Polymers A and B (90% confidence level).

The tough, flexible film provided by DynamX polymer gives hairstyles memory, so that they return to their original shape when disrupted. Consumers will perceive their styles to be moveable, yet last throughout the day.

Headbanger evaluation

In the end, however, it is the ‘on-head’ evaluations that offer the link between the objective measurements and what they mean in terms of performance. With this in mind, a Headbanger Evaluation was performed. Using a mannequin head, a hair spray containing DynamX polymer was applied to one side, and a commercial flexible hold spray was applied to the other. The mannequin head was vigorously inverted 20 times. In doing so, the hairstyle was exposed to the stress of movement, and the effectiveness of the hairspray was visually determined. Below the results of this study.

The hair treated with the DynamX® hair spray withstands the stresses of movement and retains its original shape. DynamX® polymer clearly demonstrates its ability to provide a flexible, durable hold with memory - a dynamic hairstyle.

Packaging & Availability

Storage & Handling

- Storage and Handling Information

DynamX® polymer can be stored under ambient conditions without undergoing decomposition or degradation. When not in use, the container should be kept covered to prevent dirt, dust, and moisture pick-up. Store in a cool, dry area.