Enhanced TDS

Identification & Functionality

- Chemical Family

- Manufactured By

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Coatings Industry Special Features and Benefits

GARAMITE-2578 is a rheology additive that can be used in all solvent-borne and solvent-free coating systems as a result of its very broad compatibility.

GARAMITE-2578 has the following special features and benefits:

- Pseudoplastic flow

- Improved sag resistance

- Improved anti-settling

- Supports orientation of effect pigments

As a result of its high bulk density, it is easy to use, and displays no shear sensitivity.

Applications & Uses

- Markets

- Applications

- Coating End Applications

- Coatings Industry Application

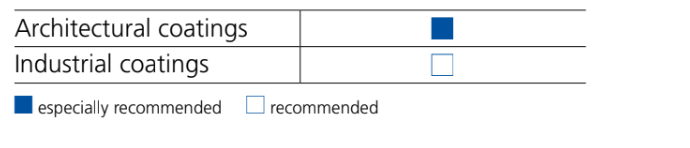

GARAMITE-2578 is recommended for the following applications.

Recommended Levels

- 0.3-2% additive (as supplied) based upon the total formulation.

- The above recommended levels can be used for orientation. Optimal levels are determined through a series of laboratory tests.

Incorporation and Processing Instructions

The additive can be incorporated in different ways. Either disperse GARAMITE-2578 directly in the millbase or add it as a 10-15% paste in solvent to the millbase or letdown. The additive should be incorporated into the solvent at sufficient shear force. When adding during the milling process, we recommend pre-dispersing in the binder and solvent at moderate shear force before adding the pigments and fillers. The effect of GARAMITE-2578 can be further increased by adding a booster or small quantities of a polar solvent or water.

Properties

- Physical Form

- Typical Properties

Value Units Test Method / Conditions Specific Weight 1.5 - 1.7 g/cc - Water Content max. 6 % - Bulk Density approx. 90 kg/m³ -

Packaging & Availability

Storage & Handling

- Storage Information

To be stored and transported at a temperature below 40°C.