Enhanced TDS

Identification & Functionality

- Manufactured By

- Technologies

- Product Families

Features & Benefits

- Industrial Additives Features

- Product Features and Benefits

- Significant increases in compressive and flexural strength, especially early age strengths

- Enhanced concrete durability

- Reduction or elimination of ASR and efflorescence

- Reduced permeability

- Enhanced resistance to chemical attack

- Improved handling and color matching

- Product Features and Benefits

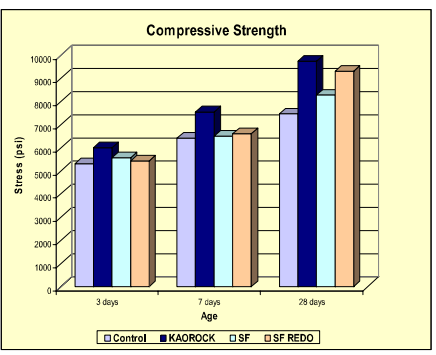

Increased Compressive strength- KAOROCK™ increases strength in all stages of the cur- ing process. It reacts with the free calcium hydroxide (lime) produced during the cement hydration process to form additional cementitious material (see Figure 1).

Figure 1: Both KAOROCK™ and silica fume showed increased strength in this laboratory test. Preliminary data on silica fume showed indicated a decrease at 1-day strength. As a result, a new silica fume sample was acquired and the test repeated.

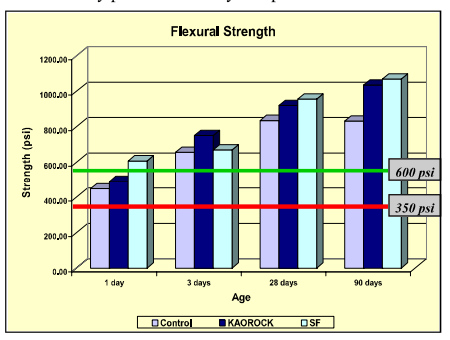

Increased Flexural Strength KAOROCK™ increases flexural strength during the cur- ing process, especially at early stages. During testing, concrete prisms were subjected to four-point bending with a water to cement ratio of 0.4 (see Figure 2). In looking at the results, metakaolin and silica fume reached 600 psi in one day indicating relevance to pavements. Metakaolin could be used to shorten the time needed before newly paved roads may be opened to traffic.

Figure 2: Average peak flexural strength (modulus of rupture) versus concrete age for w/cm of 0.40.

Reduction or Elimination of Efflorescence-Water enters the masonry struc- ture through absorption and through cracks and joints. This water dissolves the available calcium hydroxide (lime) that is produced during cement hydration. This water migrates to the surface and evaporates leaving behind the lime, which can show up as a crystalline or powdery, unattractive deposit. KAOROCK™ helps to eliminate this effect by re- acting with the free lime to form additional cement and by lowering the permeability of the structure; thereby, making it more difficult for water to move to the surface

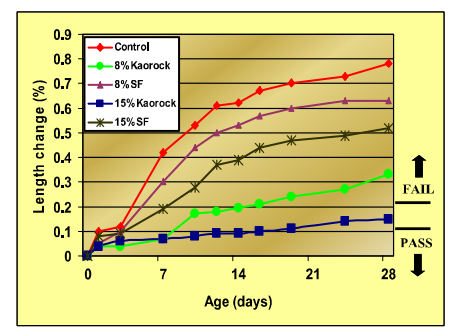

Reduction or Elimination of Alkali- Silica Reactivity (ASR)-Silica is present in concrete due to the cement hydration process, and will react with the different aggregates found in concrete. As a result, this silica can dissolve and produce a gel. When moisture is present, the gel expands and results in stresses on the structure which can lead to cracks in the concrete. KAOROCK, with its structure and re- activity, greatly reduces ASR. Since it reacts with lime, KAOROCK lowers the alkalinity of concrete, decreasing the reactivity of the silica (see Figure 3).

Figure 3: Expansion due to alkali-silica reacation, w/cm = 0.47, was measured according to the accelerated mortar bar method (ASTM C 1260). This method has proven reliable for evaluating the effective- ness of SCM's in suppressing ASR. KAOROCK™ passed while the control and samples made with silica fume failed.

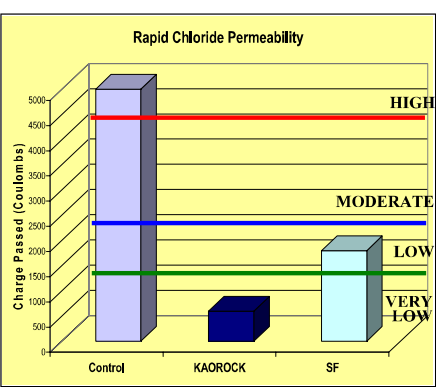

Reduced Permeability-Due to its particle shape and size, KAOROCK™ can greatly reduce the per- meability of a concrete mix. It is very effective in reduc- ing chloride ion ingress, with values in the low or very low (below 2000 Coulombs) range.

Figure 4: Experimental test data on rapid chloride permeability shows KAOROCK™ with a remarkably lower permeability than the control and silica fume.

Applications & Uses

- Industrial Additives End Use

- Product Applications

- Architectural Concrete Since KAOROCK™ is white, it will not darken the appearance of concrete. In fact, it improves the consistency of color in your concrete because the color of KAOROCK™ will always be the same. When appearance is important, as with certain precast concrete structures such as countertops and floors, KAOROCK™ is the perfect choice.

- High Performance Concrete (HPC) - KAOROCK™ has been found to meet or exceed the benefits of silica fume. It significantly increases both flexural and compressive strength, while at the same time improves the durability of the finished structure. Specifically,

- KAOROCK™ is an excellent candidate for:

- Marine environments-bridges, dams and piers

- Public roads Fast-track paving

- Concrete structures-parking areas, garages, buildings Precast concrete applications.

- Swimming Pools-KAOROCK™ produces for- mulations that are very easy to handle during application and during finishing. In addition, the particle structure of KAOROCK™ reduces permeability and eliminates efflorescence making it more durable in the chemical environment of pools.

Properties

- Typical Properties

Value Units Test Method / Conditions Loss on Ignition 0.5 % - Particle Size (Finer than 2 Microns) 65 % - Retained Fineness (325 mesh) 0.1 % - Bulk Density (Loose) 18 lbs/ft³ - Median Particle Size 1.5 microns - G.E. Brightness (Dry) min. 80 % - Surface Area 11 m²/g -