Enhanced TDS

Identification & Functionality

- Chemical Family

- Manufactured By

- Industrial Additives Functions

- Technologies

- Product Families

Features & Benefits

- Product Benefits

- PlastRetard L is the most efficient and reliable retarder for plasterboard production.

- PlastRetard L can be easily dosed using conventional volumetric metering pumps.

- PlastRetard L can reduce the water requirement of the slurry.

- PlastRetard L pose no health or environmental hazards.

- PlastRetard L is completely soluble in water for maximum efficiency.

- PlastRetard L performances is unaffected by the water/gypsum ratio.

- PlastRetard L addition can enhance the bond of paper to the gypsum core.

- PlastRetard L is unaffected by pH values between 7 and 10.

- PlastRetard L is compatible with the common additives used in plasterboard production such as starches, plasticizers and foaming agents.

Applications & Uses

- Markets

- Applications

- Industrial Additives End Use

- Fields of Application

Stucco

Calcined gypsum commonly referred to as Plaster of Paris. Mixed with water into a slurry, it hardens to a solid mass.

Plaster

Calcined Gypsum of any type, generally formulated with functional additives and/or inert aggregates.

Water/Plaster ratio (W/P)

A measure of the amount of gaging water in a plaster slurry.

Hydration

The chemical recombination of water with stucco to form gypsum crystals.

Retarder

An additive that delays initial setting and/or slows the speed of setting.

Chemical Accelerator

The opposite of a retarder; an additive that shortens the initial setting time and speeds up the setting reaction; potassium sulfate for example.

Ball Milled Accelerator

Finely ground gypsum is used to initiate the setting reaction. The gypsum is often introduced to the ball mill in combination with grinding aids, preservatives and/or other additives (sugar or starch).

The use of PlastRetard L in Plasterboard production

There are two main applications for gypsum stucco:- As a base material for the molding of prefabricated products such as plasterboard or gypsum blocks.

- As a component of powdered products such as gypsum wall plaster.

PlastRetard is a powerful liquid retarding agent that is preferred for use in the manufacture of prefabricated products. It is particularly suitable for applications in wallboard plants. The dry variety of PlastRetard that is suitable for powdered admixtures is PlastRetard PE

Since plasterboard is by far the most economically important product made from gypsum, we will concentrate on the specifics of retarder use in plasterboard production.

The conditions for an economical plasterboard operation are:- A low water/plaster ratio to minimize drying costs and maximize output

- Low weight and minimized formulation costs.

- High quality final products with minimal generation of production waste.

- Maximized operating time with minimal production stops.

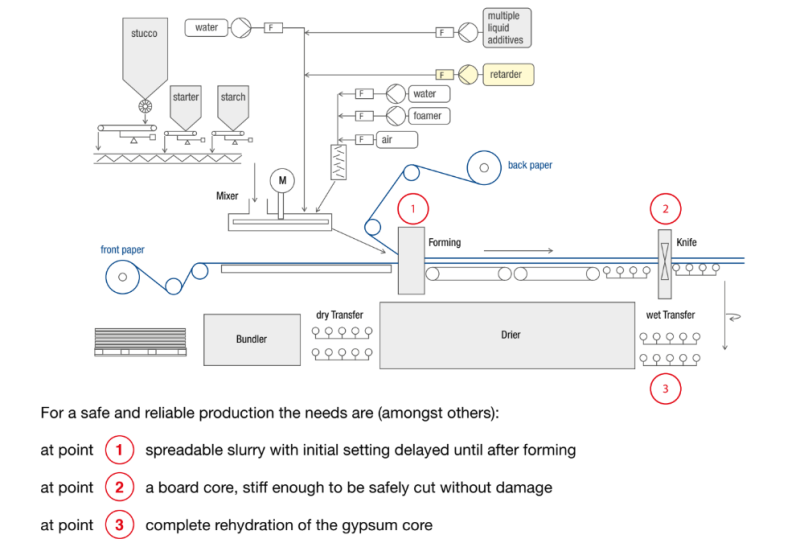

Schematic presentation of a common plasterboard production line

Those requirements translate into the following setting characteristics- Delayed stiffening

- Rapid setting speed

- Complete hydration

Applications.- PlastRetard is the most efficient and cost effective set retarder available to plasterboard manufacturers today.

- PlastRetard provides precise control of the setting reaction and helps operators to manage the production process in a better way.

- PlastRetard provides a certain amount of slurry fluidization and allows for water reduction of about 5% that translates into equivalent savings in drying costs and increases plant capacity.

- PlastRetard delays the initial setting time which helps to prevent the formation of set gypsum inside the mixer and keeps it clean. This results in a reduction of paper breaks and line stoppages and extends the net operating time of the production line.

- PlastRetard is supplied in liquid form that makes it easy to use and dose.

- PlastRetard does not contain any hazardous substances such as Nitrilotriacetic acid or Formaldehyde and is completely soluble and biodegradable.

Properties

- Physical Form

- Soluble In

- Appearance

- Brown coloured liquid

- Incompatible with

- Alumin. ium salts

- Soluble in

- Water

- Technical Data

Value Units Test Method / Conditions Solubility min. 1000 g/ml - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Auto Ignition Temperature 647 °C - Relative Density 1.22 0 - 1.25 - - Relative Vapor Density (water = 1) Same as water - - Vapor Pressure Same as water - - Flash Point min. 203 °F - pH Value 7.0 - 8.5 - - Odor Characteristic - - Appearance Brown liquid - - - Typical Composition Properties

Value Units Test Method / Conditions Viscosity 21 cPs - Water Content 55 - 57 % w/w - - Specifications

Value Units Test Method / Conditions Active Matter 43 - 45 % w/w - Density (at 20°C) 1.22 - 1.25 g/ml - Moisture Content 55 - 57 % w/w - pH (solution 10) 7.0 - 8.5 % w/w -

Technical Details & Test Data

- Product Information

PlastRetard L is carefully produced and controlled. Every step in the production process is monitored and evaluated by our laboratories to assure high quality standardized product.

Usage levels

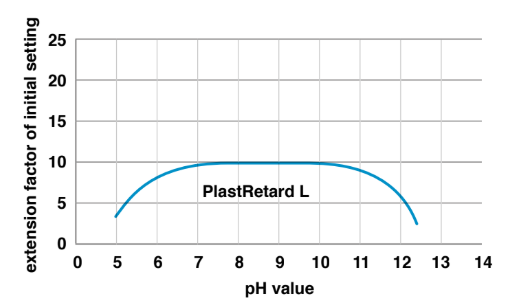

PlastRetard L can be used with any type of natural or by-product gypsum (e.g. from flue gas desulfurization, phosphoric acid, citric acid, titanium dioxide). PlastRetard L is effective over a pH range of 5 to 12. Maximum efficiency is realized between pH 7 and 10. The pH where plasterboard and other pre-fabricated products are prepared typically lies within this range.

Efficiency of PlastRetard L as a function of the pH value

Compatibility

Generally, PlastRetard L is used alone in gypsum formulations, but it is totally compatible with other retarders. It is also compatible with most other additives commonly used in plasterboard formulations. The only known incompatibility is with soluble Aluminum salts, which are not common in plasterboard production.

Safety & Health

- Toxicology & Health

Toxicology

On the basis of the results, obtained according to OECD n° 420 dated 17th December 2001, PlastRetard L is included in the category 5 of the GHS classification and consequently is non toxic. On the basis of the results and according to Italian Ministerial Decree dated 28th of April, 1997, PlastRetard L is classified not irritant for eyes and skin. PlastRetard L can therefore be handled following reasonable safety precautions and good manufacturing practices.

Ecology

On the basis of the obtained results, according to the screening method and guidelines reported in OECD n° 301/1992 and ISO 14593/1999 to which CE 648/2004 concerns, PlastRetard L is biodegradable under aerobic conditions.

No special regulations apply to transportation of PlastRetard L

Storage & Handling

- Shelf Life

- 3 years (if kept sealed, in its original packaging)

- Handling, Storage and Metering Information

PlastRetard L does not contain preservatives and it is stable when stored in its original packaging at temperatures that range from -10°C to 50°C. If diluted with water and stored over days. PlastRetard L may turn a bit gelatinous.

If dilution is required for accurate metering, it is recommended that during extended production stops any unused material be disposed and replaced with a fresh batch prior restarting production.

Alternatively, it is possible to add a preservative as Benzoic Acid in the retarder solution.

Metering is best done in undiluted form into the main process water feed using a one-way valve to prevent backflow of water. The most appropriate pump to be used is a positive displacement screw pump (eg. Netzsch, Seepex or similar).- Storage Information

Shelf life: 3 years (if kept sealed, in its original packaging)