Enhanced TDS

Identification & Functionality

- Manufactured By

- Industrial Additives Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Industrial Additives Features

- Product Benefits

The use of Plast Retard PE gives the possibility to control the setting in the range of minutes to several hours.

The use of Plast Retard PE in large and extensive production plants offers opportunities to reduce production costs, ensuring uniformity and product homogeneity.

The rate of setting and the hardening process can be adjusted advantageously to suit a long working cycle for materials applied on a big surface area. Using formulations containing Plast Retard PE, the operators will have the necessary time to apply, level and refine giving as a result a better bonding to the base.

Plast Retard PE ensures- A regular setting.

- A more homogeneous mixture.

- Improving of the quality of the gypsum surface.

- Increasing of the surface hardness.

- Minor risks of cracking.

Applications & Uses

- Industrial Additives End Use

- Different Uses of Plast Retard PE

Plast Retard PE can be used in plaster formulations for the following sector

- Molding plaster.

- Ceramics.

- Plasterboard.

- Dental plaster/Medical Plaster.

- Joint fillers.

- Adhesion Mortars.

- Gypsum blocks.

- Stucco, plastering, machine application plasters.

The gypsum ability to be retarded is strongly influenced by intrinsic characteristics, such as the calcium sulfate hemihydrate, semihydrate and anhydrite content, the presence of inorganic impurities and other salts, lime and the pH value.

Usage levels must be adjusted for each singular formulation according to the required retarding effect, related to the gypsum manufacturing process and the final application.

A suitable consistency/time graph can be obtained by adding particular additives compatible with Plast Retard PE.

The activity of Plast Retard PE depends on the type of gypsum used (natural or synthetic), for this reason specific tests should be performed in order to quantify the correct dosage for a given setting time.

Properties

- Color (Properties)

- Physical Form

- Appearance

- Ivory white colored powder

- Compatible with

- Plasticizers, Thickeners, Dispersing agents, Inert substances, Retarders, Water retentioners

- Soluble in

- Water

- SDS Physical and Chemical Properties

Value Units Test Method / Conditions Explosible Concentration min. 100 g/cc - Ignition Temperature (Layer 5 mm) min. 375 °C - Ignition Temperature (Dust Cloud) min. 450 °C - Minimum Ignition Energy min. 500 mJ - Dust Explosion Class (Kst) 1 - - Dust Explosion Value (Kst) 100 bar.m/s - Maximum Explosion Overpressure (Pmax) 8 bars-gauge - Thermal Stability min. 300 °C - Density 300 - 400 g/ml - Particle Characteristics (Median volume-equivalent diameter ) 44 - 64 mm Laser Diffraction Analyzer Auto Ignition Temperature (Cloud) 450 °C - Flammability (Solid, Gas) Combustible Dust - - pH Value (10% Solution) 7.0 - 8.5 - - Odor Characteristic - - Appearance Ivory-White/Yellow Colored Solid Powder - - - Specifications

Value Units Test Method / Conditions Active Substance min. 95 % w/w - pH Value 7.0 - 8.5 - - Volumetric Mass 300 - 400 g/l - Weight Loss max. 5 wt% - Water Content max. 5 wt% - Active Matter min. 95 %(w/w) - Solubility min. 1000 g/l - - Compatability Data

Compatibility

Plast Retard PE is compatible with inert substances, with the additives usually used in gypsum like plasticizers, surfactants and wetting agents in order to control properties like density, coverage and strength.

Technical Details & Test Data

- The Use of Setting Retarders in the Building Industry

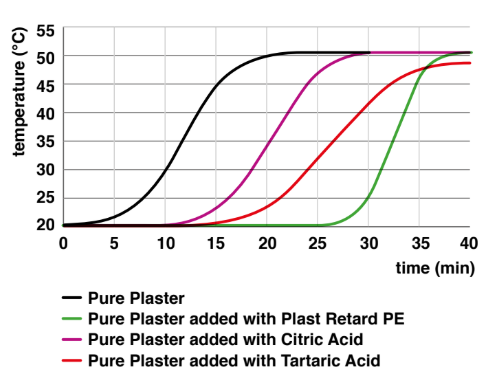

The ability of different retarders to specifically modify the setting kinetic of a certain plaster.

Additives Commonly Used in Plaster Production Industry

Plasters are applied in the building sites by craftsmen according to local traditions, which can vary considerably from one region to another.The workability of gypsums depends on a complex interplay of different parameters such as the origin of the gypsum (natural or artificial), the kind and the amount of impurities, the production (calcination process and grinding conditions) and the amount of water with which the gypsum is mixed as well the preparation and the application. Today, plasters are formulated products which contain at least one retarder, in order to provide a larger window of workability. The properties of the building materials, such as strength and porosity, depend on manufacturing techniques, the application of appropriate additives and the water/gypsum ratio. In particular, additives must be rigorously selected in order to give the best result relative to defined specifications.- PLAST RETARD PE can be used advantageously in neutral gypsum formulations avoiding the traditional use of lime. Lime is well known for modifying gypsum setting properties.

- Adding PLAST RETARD PE, on the other hand, does not modify the adherence power of gypsum formulations.

- PLAST RETARD PE is an ivory-white powder, completely soluble in water, easy to disperse in a homogeneous way for its fine and suitable granulometry.

- Parameters to be Observed when Selecting the Additives

Setting kinetics

- Open time without stiffening adapted to the kind of work.

- Slow progress in stiffening.

Rheological properties

- Easiness of distributing and planning.

- Stable Form (not flowing from the wall when worked on).

Finishing

- Crack free.

- Ability to be smoothened.

Reliability

- Stable water demand.

- Steady setting characteristics.

- Constant rheology.

Health aspects

- No toxic substances allowed.

- Skin irritants to be avoided.

Additionally, some requirements on the finished product are to be considered

- Requirements in adhesion on support.

- Requirements for hardness.

- Requirements for compression strength.

- Visual aspect.

The Retarder is one of the key additives in a plaster formulation, since it also controls the workability.- The Basics of Plast Retard PE

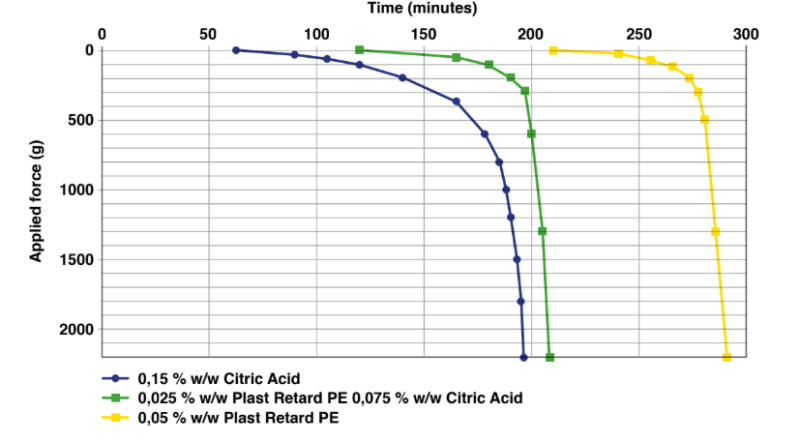

Plast Retard PE and Citric Acid

Setting Diagrams Obtained Using an Automatic Penetrometer Relative to Citric Acid/Plast Retard PE Mixtures

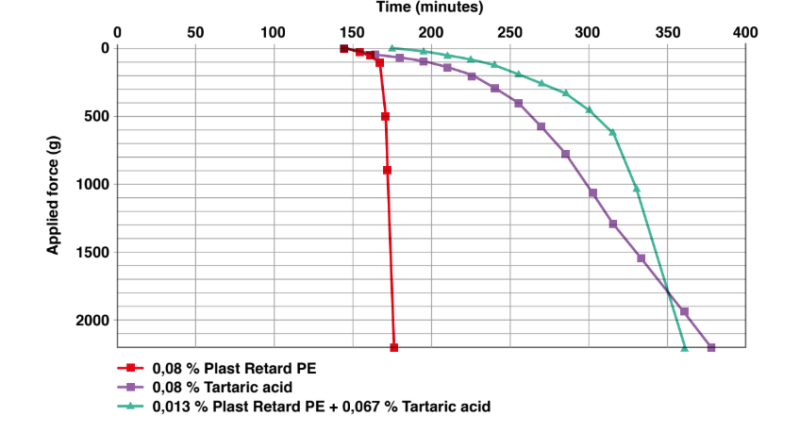

Plast Retard PE and Tartaric Acid

Setting Diagrams Obtained Using an Automatic Penetrometer Relative to Tartaric Acid/Plast Retard PE Mixture

- Activity at Different pH Values

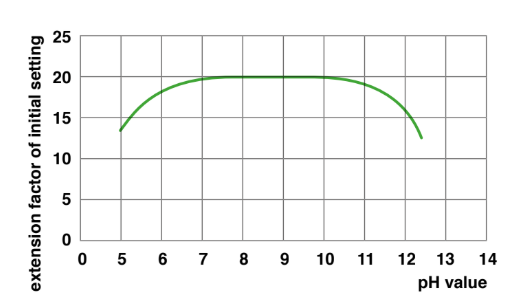

All retarders are sensitive to the pH value and some are active only at particular pH levels. Plast Retard PE is active in a pH range between 5 and 12.

Plast Retard PE shows its highest level of activity between pH 7 and 10

- Stability at Different Temperatures

Plast Retard PE can be used over a wide range of temperatures for its good thermal stability (until 300°C).

Plast Retard PE dosage (% w/w gypsum)

Conditions

Setting Time (Minutes) 0g Initial 600g Final 2200g 0 - 22 42 52 0.015 20°C 112 136 146 0.015 150°C for 20 minutes 113 137 147 0.015 170°C for 20 minutes 118 148 157 0.015 200°C for 20 minutes 120 145 154 - Proportional Correlation Between Dosage Rate and Retarding Effect

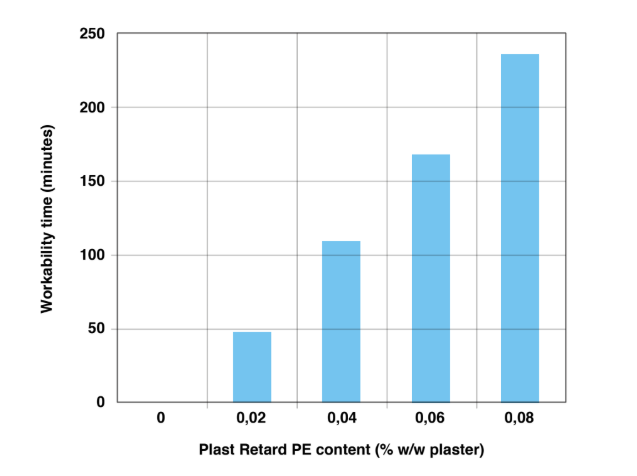

Plast Retard PE is a highly efficient setting retarder that increases the workability time proportionally to the dosage. The below figure shows an example of the linear relationship between dosage and setting time.

Workability Time Versus Plast Retard PE Dosage

- Stable Activity at Different Water Dosages

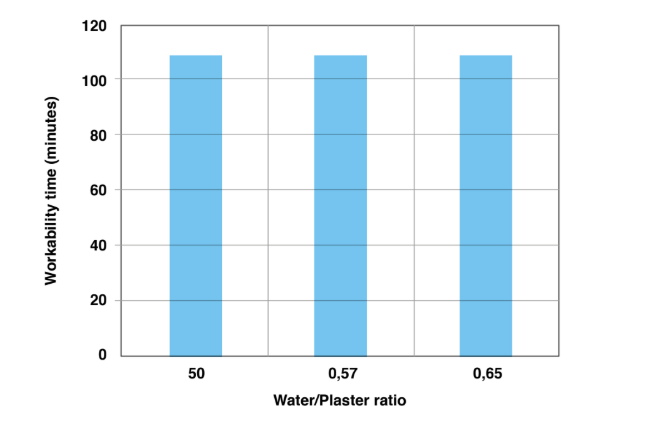

Plast Retard PE activity is not affected by the water/gypsum ratio, permitting to have a standardized quality gypsum in different working conditions.

Workability Time Versus Water/Plaster Ratio Relative to Plaster Containing 0.04% W/w Plast Retard PE

- Resistance Information

Plast Retard PE Does Not Affect Resistance

The effect of retarders on the resistance of hardened stuccoNo Retarder Plast Retard PE Plast Retard PE Retarder Content % of Plaster 0 0.08 0.4 Initial Setting Time VICAT Method (minutes) 24 40 165 Expansion (mm) 0.2 0.2 0.16 Flexural Strength (kg/cm²) 45 45 45 Compressive Strength (kg/cm²) 92 92 90

Safety & Health

- Toxicology & Health

By a toxicological point of view, Plast Retard PE is characterized by a LD50 superior to 5000 mg/Kg on male rat and it is not irritant according to 83/467/ CEE and so can be handled following the normal reasonable safety precautions according to good manufacturing procedures.

Ecology

Plast Retard PE is produced using materials of natural origin and is totally biodegradable. No special regulations apply to the transportation of Plast Retard PE.

Packaging & Availability

Storage & Handling

- Shelf Life

- 3 years (if kept sealed, in its original packaging)

- Storage Information

Plast Retard PE is a hygroscopic product. Attention is required in order to avoid the exposed surface with air humidity. The humidity adsorbed does not affect the properties as retarder, but the product is difficult to disperse when high amounts of water are adsorbed. Humidity can be avoided preserving the product in closed containers, preparing the possible pre-mixture just when it is used and avoiding high relative humidity values in the working area. Plast Retard PE does not contain preservatives and it is stable if stored in its original packaging or in

suitable sealed containers.