Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Manufactured By

- CASE Ingredients Functions

- Industrial Additives Functions

- Molecular formula

- C₉H₁₀Cl₂N₂O

- Technologies

- Product Families

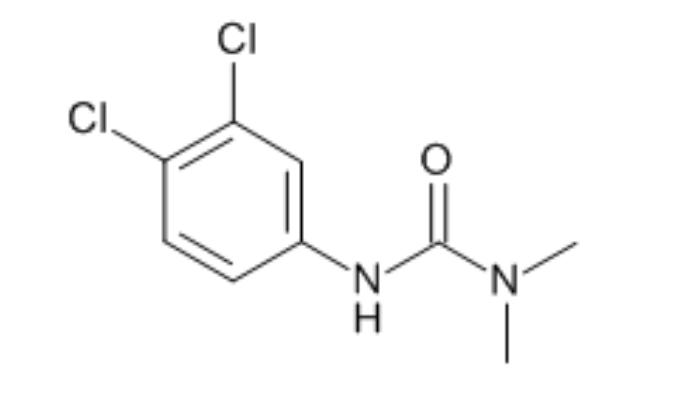

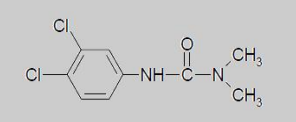

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

- Product Features and Benefits

- Technical grade of diuron (urea-derivative).

- Broad spectrum algicide which is highly effective against algae found in the air and on masonry paints.

- For the formulation of algicidal coatings and plasters for exterior applications.

- Algicidal active for the production of biocidal products.

- Modifier in epoxy resins.

- Chemical Structure

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Industrial Additives End Use

- Use Level

- -0.025, 0.015 - 0.240 % (Stains), 0.020 - 0.500 % (Silicon resin plasters), 0.050 - 0.225 % (Caulks, Sealants, Stuccos, Joint cements), 0.050 - 0.250 % (Roof coatings)

- Application information

Preventol® A 6 Preservative is a broad-spectrum algicide which is highly effective against algae found on the surface of coatings, e. g. exterior paints and plasters. It is non-volatile and not light-sensitive, has low solubility in water, good toxicological properties and low ecotoxicity in the matrix. These favorable properties, combined with the effectiveness of the product, make it ideal for use in exterior paints and plasters.

Since coatings for exterior applications are subject to both algal attack and fungal infestation, Preventol® A 6 Preservative is prevalently combined with an effective fungicide. Possible fungicidal combination partner is Preventol® MP 400-D containing the active substance 3-iodo-2-propinylbutyl carbamate (IPBC).

The excellent effectiveness of Preventol® A 6 Preservative generally allows its implementation at low dosages. A homogeneous incorporation into the coating to be protected is indispensable in order to ensure a reliable and uniform action. Typically, formulations containing Preventol® A 6 Preservative do not influence the color shade of a coating.

Okay, here is the text extracted from the image you sent:

To ensure homogeneous distribution in the finished product (particularly in paints, plasters/renders etc.), Preventol ® A 6 Preservative can be added in an early stage of the production process, e. g. by adding the preservative together with the pigments and fillers into the grind phase of the coating making operation or near the end of the manufacturing process at a point where good agitation is achieved and after the final pH adjustment is made.

Apply good agitation to ensure an even distribution of the active ingredient in the product to be protected which is necessary to guarantee a reliable biocidal effect. Moreover, LANXESS in-can preservatives should be additionally incorporated into the aq. formulation to inhibit microbial degradation during shelf storage.

In cases, where the addition of Preventol ® A 6 Preservative in an early production stage is not favored, it might also be added at the end of production process, provided it is homogeneously pre-dispersed in water and/or glycols together with an appropriate wetting and dispersing agent beforehand.

It is recommended to conduct preliminary tests on compatibility and biological effectiveness for each new application.

The approved dosage levels ranges are provided in the chapter "Directions for use" further below, but variables such as pH, temperature, initial germ count or intended storage time of the product to be preserved should be taken into account. 1

- Product Usage

It is a violation of Federal law to use this product in a manner inconsistent with its labeling.

This product must be used in a way that will prevent contact with workers and other persons.

Application levels presented below are laboratory evaluations and are typical for the use area indicated. The application ranges 1 are based on a weight/weight of Preventol® A 6 Preservative.

Preventol® A 6 Preservative should be added to paint, coating or other formulations near the end of the manufacturing process at a point where good agitation is achieved and after the final pH adjustment is made.

Properties

- Physical Form

- SDS Physical and Chemical Properties

Value Units Test Method / Conditions Appearance Powder - - Physical State Solid - - Odor Amine-like - - Melting Point 154 - 159 °C - Flammability (solid, gas) May form explosive dust - air mixture - - Self-Ignition 401 °C - Burning Number (at 20°C) 3 - VDI 2263-1 Vapor Pressure (at 20°C) max. 0.00014 hPa - Density (at 20°C) 1.453 g/cm³ - Bulk Density 280 - 370 kg/m³ - Solubility in Water 0.0285 - 0.029 g/L - Ignition Temperature 250 °C - Decomposition Temperature min. 200 °C - Dust Explosion Class St1 - Physico-Chemical Properties

Value Units Test Method / Conditions Active Ingredient approx. 98.4 % - Appearance Powder - - - Microbiological Values

Value Units Test Method / Conditions Desmodesmus communis 0.1 ppm - Nostoc commune 0.1 ppm - Phormidium tergestinum 0.01 ppm - Scenedesmus vacuolatus 0.01 ppm - Stichococcus bacillaris 0.1 ppm - Trentepohlia anulata 1 ppm - - Characteristics

Value Units Test Method / Conditions pH Value (at 1%) approx. 7.0 - - Bulk Density approx. 17.5 - 23.1 lb/ft³ - Vapor Pressure (at 25°C) approx. 2.0 - 10 hPa - Initial Melting Point approx. 309 - 318 °F - Relative Self-Ignition Temperature min. 753 °F - Solubility in Water 0.0285 - 0.029 g/L - Solubility in Acetone 47.2 g/L - Solubility in Xylene 1.47 g/L - Solubility in Butyl glycol 62 g/L -

Regulatory & Compliance

- Grade

Safety & Health

- Health and Safety Information

Appropriate literature has been assembled which provides information concerning the health and safety recautions that must be observed when handling the LANXESS products mentioned in this publicatio or materials mentioned which are not LANXESS products, appropriate industrial hygiene and othe safety precautions recommended by their manufacturers should be followed. Before working with any of these products, you must read and become familiar with the available information on their hazards, proper use, and handling. This cannot be overemphasized. Information is available in several forms, e.g.. material safety data sheets and product labels. Consult your LANXESS Corporation representative or contact the LANXESS Product Safety and Regulatory Affairs Department in Pittsburgh, PA.

Packaging & Availability

Storage & Handling

- Shelf Life

- 2 years

- Storage Conditions

Preventol® A 6 Preservative hydrolyses in strong acids and alkalis. At temperatures above 680 °F / 200 °C beginning pyrolysis. If correctly stored and kept in the original sealed container, the shelf life is at least 24 months.