Enhanced TDS

Identification & Functionality

- Carrier

- Chemical Family

- Manufactured By

- Agrochemical Functions

- CASE Ingredients Functions

- Cleaning Ingredients Functions

- Fluids & Lubricants Functions

- Industrial Additives Functions

- Technologies

- Product Families

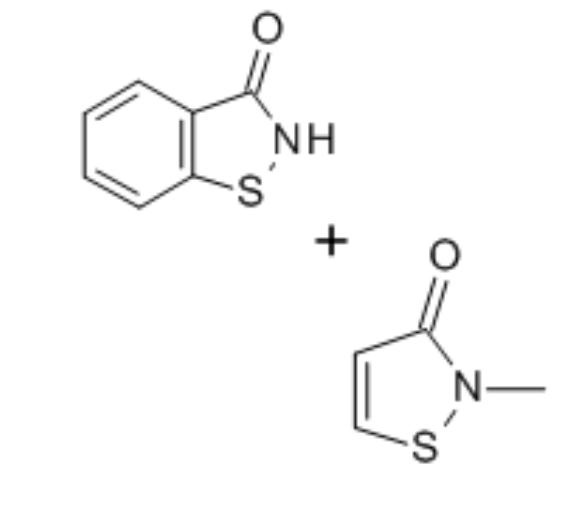

- Chemical Structure

Features & Benefits

- Labeling Claims

- Product Features and Benefits

- Aqueous solution of 1,2-Benzisothiazolin-3-one (BIT) and Methylisothiazolin-3-one (MIT).

- For the preservation of aqueous technical preparations such as aqueous paints and coatings, polymer emulsions, plasters, knifing fillers, pigment pastes, paper coatings, inks, synthetic and natural adhesives, cleaners and detergents, and similar products.

- Broad spectrum of antimicrobial activity, particularly against bacteria.

- VOC- and solvent-free.

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Fluids & Lubricants Type

- Coating End Applications

- Fluids & Lubricants End Use

- Home Care Applications

- I&I Cleaning Applications

- Industrial Additives End Use

- Application information

Preventol® BM 5 is water based in-can preservative containing benzisothiazolinone (BIT) and methisothiazolinone (MIT). This combination offers a broad spectrum against bacteria and fungi.

Preventol® BM 5 is an aqueous solution that is free of solvent or VOC components. The product is stable in alkaline conditions (pH up to approx.10). Preventol® BM 5 is especially effective in applications (e.g. interior paints and polymer emulsions) where the microbial protection of the low or no VOC products is needed. Preventol® BM 5 can used in the industrial product manufacturing up to processing temperature of 140 °F / 60 °C.

For most material preservation formulation, Preventol® BM 5 can be added at any stage of the manufacturing process but it is best to add it in the feed water. Adding to the feed water provides microbial control from the earliest stage of production. In higher temperature greater than 140 °F / 60 °C or pH values >10, Preventol® BM 5 should be added at the end of the manufacturing process when temperature have been cooled below 140 °F / 60 °C. Once the Preventol® BM 5 is added, the formulation should be stirred until uniformly distributed.

The product is compatible with most raw materials and contains no bivalent metal salts. Preventol® BM 5 can be incorporate directly into a ready-to-use formulations. Incompatibility problems may occur in the presence of strongly oxidizing or reducing agents (e.g. persulfates, sodium meta-bisulfite, dithionites, etc.). The approved dosage level ranges are provided in the chapter “Direction for use” further below, but variables such as pH, temperature, initial microbial load or intended storage time of the product to be preserved should be taken into account.

Material Compatibility

Material Compatibility Preventol® BM 5 is compatible with storage tanks made using high quality stainless steel. Compatibility tests are recommended for other metallic materials Plastic materials like PE, HDPE PTFE are compatible and suitable for handling and storage of Preventol® BM 5. As with any product, use of the products mentioned in this publication in a given application must be tested (including field testing, etc.) by the user in advance to determine suitability.- Product Usage

Directions for use

It is a violation of Federal law to use this product in a manner inconsistent with its labelling. The following guidance is given as an approximation for each use pattern, but field-testing is recommended to achieve optimum effectiveness.

Material PreservationKey (Application) Value (Dosage %)

Adhesives and Tackifiers 0.10 - 0.50% Paints, Coatings and Stains 0.10 - 0.50% Electrodeposition Systems up to 0.60% 6000 ppm

Electrodeposition Systems - Tankside Addition up to 0.60% 6000 ppm (weekly)

Electrodeposition Systems - Maintenance Addition up to 0.60% 6000 ppm (weekly)

Electrodeposition Systems - Treatment of Paint Components up to 0.50% Pigments, Dyes and Filler Suspensions 0.03 - 0.30% Consumer, Household, and Institutional Products 0.012 - 0.40% Polymer Emulsion 0.10 - 0.50% Building Material Preservation 0.10 - 0.50% Inks and Fountain Solutions 0.10 - 0.50% Concrete Admixtures 0.10 - 0.50% Metalworking Fluids - Tankside 0.15 - 0.50% Water Based Agricultural Pesticide Concentrates 0.05 - 0.50% For the In-Can preservation of building materials, adhesives and tackifiers, paints and coatings, electrodeposition systems, pigments, dyes and filler suspensions, consumer, household and institutional products, inks and fountain solutions, concrete admixtures, metalworking fluids, and water based agricultural pesticide concentrates.

Properties

- Physical Form

- Soluble in

- Water

- SDS Physical and Chemical Properties

Value Units Test Method / Conditions Appearance Clear to slightly hazy liquid. - - pH Value (at 10% concentration) 8 - 9 - - Melting Point 30 °F - Vapor Pressure (at 20°C) 18.75 mmHg - Vapor Pressure (at 50°C) 84 mmHg - Vapor Pressure (at 55°C) 108.75 mmHg - Density 1.015 - 1.04 g/cm³ - Density 68 g/cm³ - - Physico-Chemical Properties

Value Units Test Method / Conditions Active Ingredient approx. 5 % - Appearance Aqueous solution - - - Characteristics

Value Units Test Method / Conditions Density 1.015 - 1.040 g/cm³ - Dynamic Viscosity 1.4 mPa.s - Kinematic Viscosity 1.4 mm²/s - Boiling Point (at 1013 mbar) 212 °F - Flash Point min. 212 °F Closed Cup Vapor Pressure (at 20°C) 25 hPa - Vapor Pressure (at 50°C) 112 hPa - Ignition Temperature min. 932 °F - pH Value (at 10%) 8 - 9 - -

Packaging & Availability

Storage & Handling

- Shelf Life

- 1 year

- Storage Conditions

Product should be stored in the original sealed package. The shelf life of the Preventol® BM 5 is at least one year. Avoid storing the product in temperature below 32 °F / 0°C and above 104 °F / 40 °C.