Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Manufactured By

- Pigment Type

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

Properties

- Color (Properties)

- Physical Properties

Value Units Test Method / Conditions Resistance (aqueous Slurry) min. 2 k ohm-cm - pH Value (aqueous Slurry) 8.5 - - Mean Particle Size 0.29 μm - Specific Gravity 4.2 - - Organic Treatment 0.2 wt% - Alumina Content max.1.7 wt% - Titanium Dioxide Content min. 97 wt% - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Oxidising Properties The substance or mixture is not classified as oxidizing. - - Explosive Properties Not Explosive - - Decomposition Temperature The substance or mixture is not classified self-reactive - - Relative Density 3.6 - 4.3 - - Insoluble in Water - - Flammability (Solid, Gas) Will not burn - - Boiling Point 3000 °C - Melting Point 1843 °C - Odor Odorless - - Appearance White crystalline - - - Product Properties

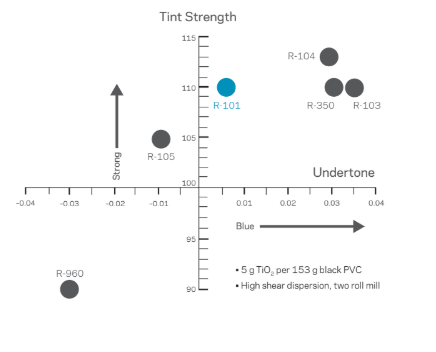

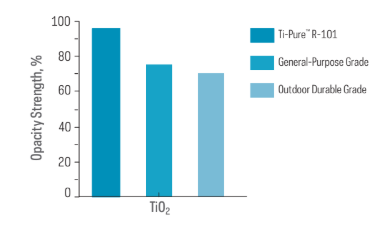

Ti-Pure™ R-101 is designed primarily for plastic applications. Ti-Pure™ R-101 provides high opacity with a neutral undertone

- Optical Properties

The low level of surface treatment on Ti-Pure™ R-101 gives it excellent dry blend dispersion.

- Dry Blend Dispersion Performance

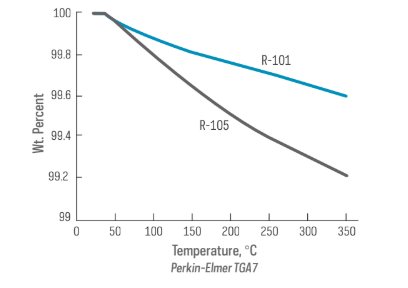

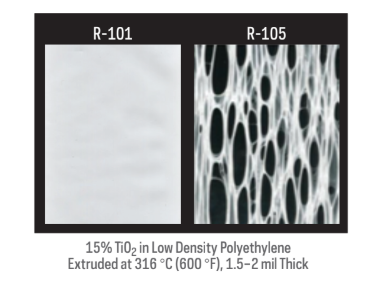

A major advantage of Ti-Pure™ R-101 is its low level of crystalline and surface adsorbed water. This characteristic gives superior performance in high-temperature polyolefin extrusion coating operations sensitive to lacing.

- Thermogravimetric Measurement of TiO2 Volatility

Ti-Pure™Titanium Dioxide Lacing Resistance

Regulatory & Compliance

- Certifications & Compliance