Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Manufactured By

- Pigment Type

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

Properties

- Color (Properties)

- Physical Properties

Value Units Test Method / Conditions Titanium Dioxide Content min. 96 wt% - - Typical Properties

Value Units Test Method / Conditions Resistance min. 4 k ohm-cm - pH Value 6.5 - - Specific Gravity 4.1 - - Organic Treatment 0.2 wt% - Alumina Content max. 3.2 wt% - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Oxidising Properties The substance or mixture is not classified as oxidizing. - - Explosive Properties Not Explosive - - Decomposition Temperature The substance or mixture is not classified self-reactive - - Relative Density 3.6 - 4.3 - - Insoluble in Water - - Flammability (Solid, Gas) Will not burn - - Initial Boiling Point 3000 °C - Melting Point 1843 °C - Odor Odorless - - Appearance White crystalline - - - General Properties

Opacity Strength High Undertone Tint Very Blue Dispersible in (Plasticized Vinyl) Very Good Dispersible in (Plasticizers) Fair Dispersible in (Dry Blending Operations) Good Dispersible in (Melt Compounding) Excellent Flocculation Resistance Very Good Discoloration Resistance Excellent Weathering Resistance Good - Properties

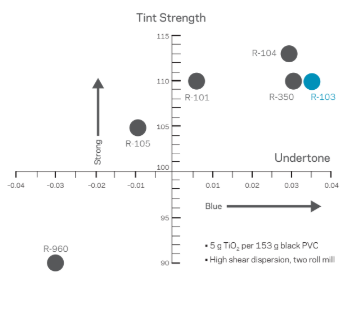

Figure 1. Optical Properties

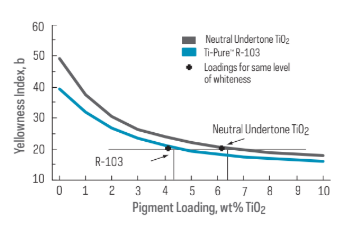

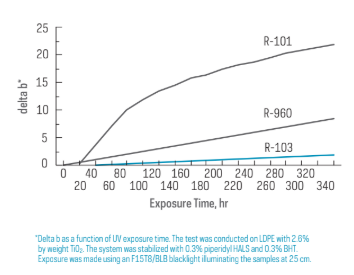

The exceptional blueness of Ti-Pure™ R-103 Titanium Dioxide Pigment is of particular value in naturally colored resin systems like ABS. As much as 30% less TiO₂ can be used to achieve finished product requirements compared to neutral undertone pigments (Figure 2). The unique alumina surface treatment of Ti-Pure™ R-103 Titanium Dioxide Pigment provides excellent discoloration resistance.

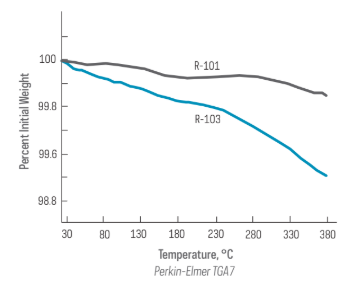

The volatility of Ti-Pure™ R-103 Titanium Dioxide Pigment allows acceptable processing in all applications except high temperature thin PE cast film or PE extrusion coating. For these demanding applications, Ti-PureTM grades R-101, R-104, or R-350 are recommended. Ti-Pure™ R-103 Titanium Dioxide Pigment is excellent in polyolefin or engineering resin applications requiring high opacity strength, very blue tint, excellent dispersion, and discoloration resistance. Ti-Pure™ R-103 Titanium Dioxide Pigment’s surface treatment allows its use in lead-stabilized PVC systems, while still providing controlled chalking in exterior PVC applications. Ti-Pure™ R-103 Titanium Dioxide Pigment surface treatment makes it a preferred choice in liquid systems such as plastisols, liquid colorants, etc. Its blue tinted value and high tint strength in plastics products coupled with its ease of dispersion into liquid systems makes Ti-Pure™ R-103 Titanium Dioxide Pigment a very good grade for liquid colorant concentrates, flexible PVC, and PVC plastisol applications.

Figure 2. Value of Blue Undertone in “Colored” Resin Exhibits Prepared in Cycloac® TD 1001 ABD

Figure 3. Ti-Pure™ R-103 Discoloration Resistance in HALS Stabilized LDPE

Figure 4. Thermo-Gravimetric Measurement of TiO₂ Volatility

Packaging & Availability

Storage & Handling

- Shipping Information

Ti-Pure™ R-103 rutile titanium dioxide is available in two recyclable package types to meet your needs:

- 25 kg polyethylene bags

- 1 metric ton (1,000 kg) flexible intermediate bulk containers

Ti-Pure™ R-103 is listed with NSF International for use in plastic pipe products.