Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Manufactured By

- Pigment Type

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

Applications & Uses

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Uses

- Ti-Pure™ R-104 Titanium Dioxide Pigment is designed primarily for plastic applications.

- The properties ofTi-Pure™ R-104 Titanium Dioxide Pigment are especially valuable where high concentrations of pigment are desired in thermoplastic masterbatches and where minimal effect is desired on melt flow.

- This, combined with the following, makesTi-Pure™ R-104 Titanium Dioxide Pigment a valuable asset to the color formulator.

- Ti-Pure™ R-104 Titanium Dioxide Pigment has a unique surface treatment that causes it to have minimal effect on the melt flow properties of masterbatches.

- This allows the masterbatch producer to achieve high loadings in relatively low melt index resins and still have a melt processible material.

Properties

- Color (Properties)

- Physical Form

- Dispersible in

- Dry Blending Operations, Weathering Resistance, Lacing Resistance, Effect on Melt Flow, Thermoplastics

- Physical Properties

Value Units Test Method / Conditions Specific Gravity 4.2 - - Organic Treatment (carbon) 0.3 wt% - Alumina Content max. 1.7 wt% - - Typical Properties

Value Units Test Method / Conditions Undertone Tint Very Blue - - Opacity Strength High - - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Oxidising Properties The substance or mixture is not classified as oxidizing. - - Explosive Properties Not Explosive - - Decomposition Temperature The substance or mixture is not classified self-reactive - - Relative Density 3.6 - 4.3 - - Flammability (Solid, Gas) Not expected to form explosive dust-air mixtures. - - Flammability (Solid, Gas) Will not burn - - Insoluble in Water - - Initial Boiling Point 3000 °C - Melting Point 1843 °C - Odor Odorless - - Appearance White crystalline - - - Melt Index

Melt Index Effects in Three Resins

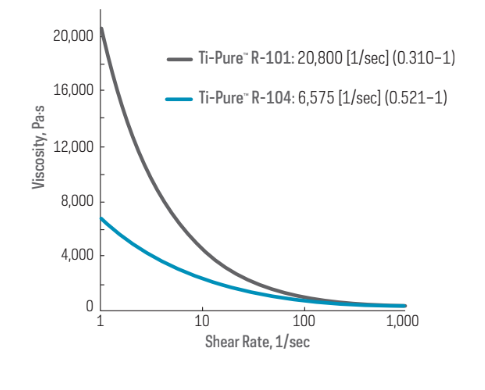

Pigment wt% 12 22 70 R-101 50 7.4 R-104 50 9.3 R-101 60 4.0 R-104 60 8.1 R-101 70 nil nil R-104 70 5.4 10.2 R-101 80 nil R-104 80 10.6 While melt index is a good measure of relative performance, the method does not reveal much about actual process conditions. Capillary melt flow measurements fill this gap, allowing viscosity to be measured over the normal range of processing equipment.

Technical Details & Test Data

- Techical Information

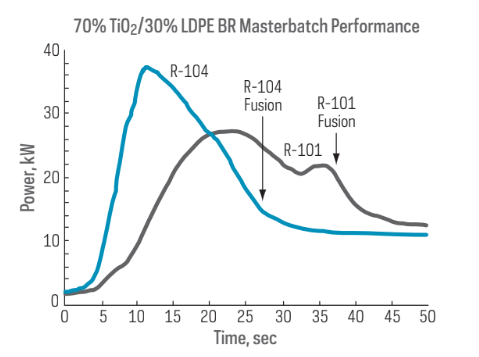

Figure.1 shows the profound reduction in viscosity that can be achieved with Ti-Pure™ R-104 Titanium Dioxide Pigment in a 70% low density polyethylene masterbatch. Ti-Pure™ R-104 Titanium Dioxide Pigment easily “wets” with the surface of the thermoplastics and can dramatically increase process rates during preparation of thermoplastic masterbatches in certain types of compounding equipment. A typical internal mixer power curve is shown in Figure 1, which compares Ti-Pure™ R-104. It is apparent that cycle time reductions of up to 25% can be readily achieved.

Melt Rheology of 70% TiO2 Masterbatch (12 MFI LDPE at 190 °C)

Figure 2, which compares Ti-Pure™ R-104 Titanium Dioxide Pigment. It is apparent that cycle time reductions of up to 25% can be readily achieved.

Internal Mixer Power Curve (R-104 versus R-101 Standard)