Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Manufactured By

- Pigment Type

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

Applications & Uses

- Plastics & Elastomers End Uses

- Suggested Use Levels

Ti-Pure™ R-105 is recommended for outdoor plastics, especially PVC window profile applications. Ti-Pure™ R-105 utilizes silica encapsulation technology to minimize interaction of the TiO₂ surface with the surrounding environment. This minimizes “chalking,” crazing, and other surface deterioration frequently seen in outdoor applications. Ti-Pure™ R-105 surface treatment also is optimized for dry flow conveyability and dispersion within plastics.

Properties

- Color (Properties)

- Dispersible in

- Dry Blending Operations

- Physical Properties

Value Units Test Method / Conditions Specific Gravity 4 - - Carbon Content 0.2 wt% - Silica Content max. 3.5 wt% - Alumina Content max. 3.2 wt% - Titanium Dioxide Content min. 92 wt% - - Typical Properties

Value Units Test Method / Conditions Melt Compounding Operations Very Good - - Dispersible in Plasticized Vinyl - - Weathering Resistance Excellent - - Undertone Tint Neutral - - Opacity Strength Medium - - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Oxidising Properties The substance or mixture is not classified as oxidizing - - Explosive Properties Not Explosive - - Decomposition Temperature The substance or mixture is not classified self-reactive - - Relative Density 3.6 - 4.3 - - Insoluble in Water - - Flammability (Solid, Gas) Will not burn - - Initial Boiling Point 5432 °F - Melting Point 3349 °F - Odor Odorless - - Appearance White crystalline - -

Technical Details & Test Data

- Optical Properties

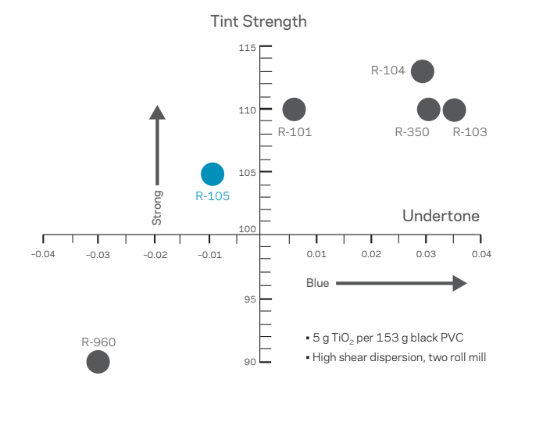

Ti-Pure™ R-105 optical performance is exceptionally useful for exterior PVC products. Ti-Pure™ R-105 has an excellent combination of brightness, neutral undertone

and moderate tinting strength..

- Durability

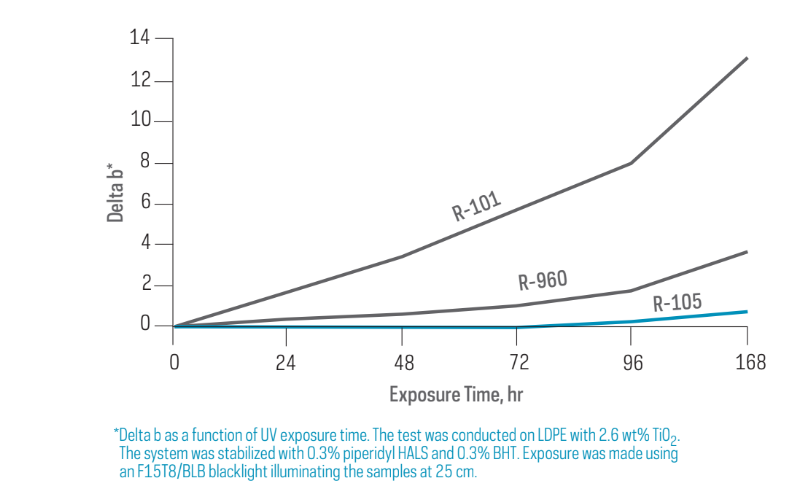

Ti-Pure™ R-105 technology has optimized SiO₂ encapsulation for durability. By providing a uniform, complete coating of the TiO₂ surface, the SiO₂ layer acts as a barrier to prevent the surface of the TiO₂ from reacting with the polymer or additives. This is especially important in outdoor applications where the UV energy absorbed by the TiO₂ particle may induce photocatalytic reactions. Ti-Pure™ R-105 provides excellent gloss retention in outdoor PVC applications.

Gloss Retention Lead Stabilized PVC Profile.

% Initial Gloss 18 months (Florida, USA) 18 months (Bandol, France)

R-103 (“chalking” grade) 14 15 R-105 100 64 - Discoloration Resistance

The combination of surface treatments used in Ti-Pure™ R-105 provides excellent resistance to photo-induced discoloration. Ti-Pure™ R-105 minimized lead graying in PVC systems and phenolic yellowing in polyethylene systems.

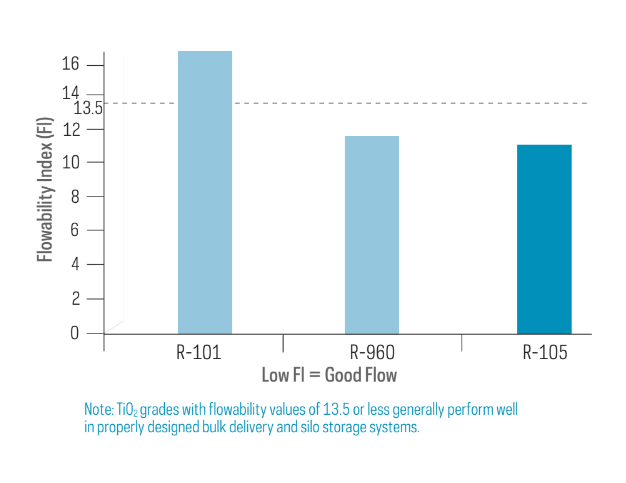

- Conveyability

Ti-Pure™ R-105 surface treatment allows for use in bulk delivery and conveying systems. The combination of inorganic and organic surface treatment optimizes R-105’s flowability.

Bulk Flow Performance

Packaging & Availability

- Country Availability

- Shipping Information

Ti-Pure™ R-105 rutile titanium dioxide is available in two recyclable package types to meet your needs:

• 25 kg polyethylene bags (Paper bag available in Asia Pacific only)

• 1 metric ton (1,000 kg) flexible intermediate bulk containers

Ti-Pure™ R-105 can also be delivered by bulk truck to European customers using silo systems. Please contact your local Ti-Pure™ account manager for details.