Enhanced TDS

Identification & Functionality

- INCI Name

- Ingredient Origin

- Manufactured By

- Cosmetic Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Benefit Claims

- Labeling Claims

- Product Benefits

- Equal performance to synthetics

- Nonionic - compatible with today's leading thickeners

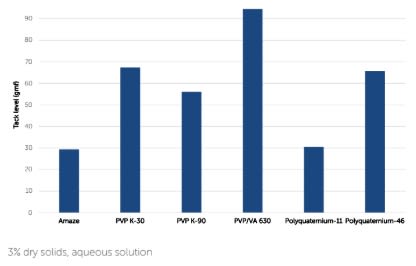

- Low tack on the hair and in the hand

- Light, clean feel

- Excellent humidity resistance

- Economical

- Pure, naturally based product

- Product Compatibility

The best plasticizers for Amaze™ are natural-based and/or cationic ingredients, which have similar polarity to the starch. A small amount of cationic improves the substantivity of Amaze™ to the hair. The use of hydrophobic and silicone-based plasticizers is not recommended, due to the possibility of increased flaking from the hair. Amaze™ works particularly well with proteins and cationic celluloses (such as polyquaternium-4 and -10 Celquat® polymers), because these ingredients are polymeric film formers and have a similar hydrophilic nature. When used in combination, they promote adhesion and minimize flake on hair.

Ingredient compatibility

Amaze™ is a nonionic starch and is compatible with anionic, cationic, nonionic and amphoteric surfactants. To thicken the Amaze starch, the following rheology modifiers are recommended:- Acrylates/C10-30 Alkyl Acrylate Crosspolymer.

- Structure® series (2001, 3001)

- Hydroxyethylcellulose (forms hazy, all-natural gel)

Preservative system - Using a 2% aqueous Amaze starch solution, the following preservatives were found to be most effective:

- 1% Germaben II (Propylene Glycol and Diazolidinyl Urea and Methylparaben and Propylparaben, Sutton Labs)

- 0.2% Dowicil 200 (Quaternium-15, Dow Chemical)

- 0.5% Glydant Plus Liquid (DMDM Hydantoin and Iodopropynyl Butylcarbamate, Lonza)

Other preservatives may be effective; however, microbial challenge testing is recommended.

Clarity - Either moderately heating the Amaze starch solution or raising the formula pH will help to improve the dispersion clarity. The combination of heat with an emulsifier at higher pH (approx. 8.0) can provide a solution that is close to crystal clear. Raising the pH of an Amaze/Carbomer gel will slightly improve the gel clarity. The gel will look clear in the hand.

Amaze™ performs well with several types of natural plasticizers, including:- Cationic celluloses (polyquaternium-4 and -10)

- Hydrolyzed proteins

- Quaternized proteins

- Quaternary ammonium compounds

- Amino acids (silk)

- Hydrolyzed keratin

- Hydrolyzed collagen

- Glycerin

- Glycols (propylene, butylene)

- Sorbitol

Applications & Uses

- Markets

- Applications

- Application Format

- Hair Care Applications

- Use Level

- 0.5 - 5% (Styling aids, depending on hold level)

- Applications and Uses

Mousses, gels, and styling lotions made with Amaze™ offer outstanding aesthetic properties on hair. While stiffness and hold match up to commercial alternatives, tack-time, flexibility and manageability are significantly improved with the use of Amaze™. In mousses, Amaze™ can be used to replace various nonionic polymers or extend cationic polymers for improved cost effectiveness. Gels can be produced that are high in performance and clear in the hand. In all cases, Amaze™ can create significant cost savings for the manufacturer. Amaze™ is also an excellent choice for marketers demanding high performance from a natural product. Amaze™ raises the standards of natural fixatives to the performance of a synthetic.

- Formulation Guidelines

More than ever, your customers demand performance and economy. Amaze™ delivers in a wide variety of formulations. Amaze™ can give you superior products and wide latitude to optimize your formulation costs. Amaze™ can be used in a wide variety of formulations, in the same way as most nonionic polymers. Typical use levels are 0.50-5.0%, depending on the hold level in any styling application.

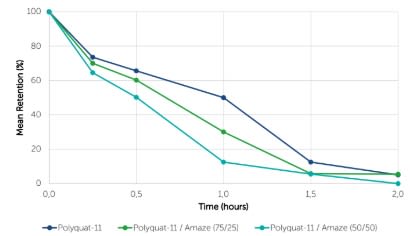

In mousses - Amaze™ can be used alone as a high performance, economical alternative to various non-ionic polymers. The result is naturally based formulations with performance similar to synthetic polymers. Amaze™ can be blended with synthetic cationic polymers like Polyquaternium-11 or Polyquaternium-16 to reduce the cost of the formulation. Better economies are achieved without sacrificing performance.

In gels - Amaze™ can be used as a direct substitute for nonionic polymers. This produces a high performance, natural gel with hand clarity. The low tack properties also offer an aesthetic advantage over synthetic alternatives. Amaze™ can be directly dispersed in water, and needs no neutralization. It can be handled as most dry personal care ingredients. Although Amaze™ is a water soluble polymer, it can tolerate ethanol in formulations. Some formulations can tolerate up to 30% ethanol. Shampoo removability is excellent. In addition Amaze™ can be used in place of nonionic synthetic polymers in a broad range of Personal Care products.

Properties

- Physical Form

- Soluble In

- Compatible with

- Anionic, Nonionic, Amphoteric surfactants, Cationic

- SDS Physical and Chemical Properties

Value Units Test Method / Conditions Density (at 25°C) 1500 kg/m³ - Explosive Properties Not Explosive - - Dust Deflagration Index 12 m.b/s - Dust Explosion Class St1 - - Lower Explosion Limit 125000 mg/m³ - Ignition Temperature min. 100 °C - pH Value (at 2 % solution) 5.5 - 7.5 - - Soluble in Water - - Color White Form Powder Odor Mild Flammability (solid, gas) Not classified as a flammability hazard. May form combustible dust concentrations in air during processing, handling or other means. Oxidizing Properties The substance or mixture is not classified as oxidizing.

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Product Performance Properties

- Amazing hold and control in styling aids - Amaze™ is a nonionic, natural polymer based on modified corn starch. It can be directly compared to most nonionic and cationic polymers. In most cases, Amaze™ provides a similar performance profile with improved aesthetic properties.

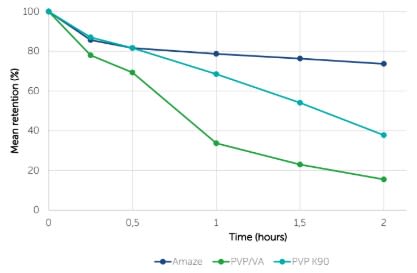

- Humidity Resistance - In gel systems, Amaze™ provides excellent curl retention versus today’s nonionics. In mousse systems, curl retention is similar to PVP/VA (60/40), as the surfactants in the mousse tend to plasticize the Amaze™. The degree to which this takes place is dependent on the final formulation.

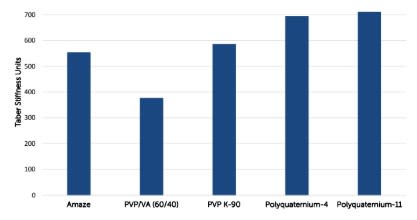

- Stiffness - The stiffness of Amaze™ is similar to other cationic and nonionic polymers. Certainly, the performance of any polymer is affected by the formulation, but in the same formulation, Amaze™ provides stiffness comparable to most products at equal dry solids levels.

- Test Data

Diastron tack test - Since Amaze™ is a natural polymer, it provides a clean, non-tacky feel. Diastron tack testing indicates it to be much lower than other synthetic products. This translates to more elegant formulations for your customer.

Safety & Health

- Health and Safety

This product may be used in spray applications having a droplet particle size greater than 50 microns. The product has not been properly evaluated for safety clearance for use in pumps and/or aerosols with particle sizes less than 50 microns.

Packaging & Availability

Storage & Handling

- Storage Conditions

Amaze™ is supplied in 90.7 kg (200 lb) drums. When not in use, the container should be kept covered to prevent dirt, dust, and moisture pick-up. Store in a cool, dry area.