Enhanced TDS

Identification & Functionality

- Manufactured By

- Agrochemical Functions

- CASE Ingredients Functions

- Cleaning Ingredients Functions

- Industrial Additives Functions

- Technologies

- Product Families

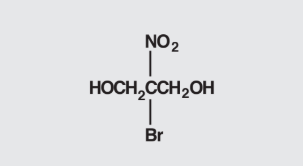

- Chemical Structure

Features & Benefits

- Benefits

- Efficacy against Pseudomonas

- Control of slime-forming bacteria

- Control of anaerobic organisms responsible for microbial-induced corrosion

- Control of Legionella pneumophilia

- Application approvals in numerous international markets

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Adhesive & Sealant End Applications

- Coating End Applications

- Home Care Applications

- Industrial Additives End Use

- Ink & Toner End Applications

- Application Information

Applications Purpose Suggested Concentrations of BIOBANᵀᴹ BP-PLUS Preservative How to Apply Pulp and Paper To control slime-forming bacteria

in process water and bulk pulp.10-250 ppm of BIOBANᵀᴹ BP-PLUS

preservative for process water.

50-250 ppm of BIOBANᵀᴹ BP-PLUS

Preservative for bulk pulp.Add to the hydropulper,

machine chest or

stock chest.Water Treatment To control slime-forming bacteria in

recirculating water cooling towers,

evaporative condensers, industrial

process water, and air scrubber, air

conditioner and humidifier systems.25-100 ppm of

BIOBANᵀᴹ BP-PLUS Preservative.Add directly into the

sump or basin at any point

where there is adequate

agitation to ensure

dissolution.Absorbent Clays,

Corn Cobs,

& Ground WoodTo inhibit the growth of

odor-causing bacteria.25-200 ppm of

BIOBANᵀᴹ BP-PLUS Preservative.Impregnate directly into

clay, cob, or wood in a

prepared solution.Adhesives For preservation of water-based

adhesives including dextrin,

clay and polyvinyl acetate

containing systems.100-5000 ppm of

BIOBANᵀᴹ BP-PLUS Preservative.Add to the final formulation. Starch and Pigment

SlurriesTo control bacteria in aqueous starch

suspensions and pigment slurries.100-500 ppm of

BIOBANᵀᴹ BP-PLUS Preservative.Add close to the end of the

manufacturing process.Paints, Latex and

Antifoam EmulsionsFor in-can preservation and

to prevent bacterial spoilage

during storage of latex emulsion

concentrates and latex emulsion-

based paints. Also, for the

preservation of silicone and other

antifoam emulsion systems.100-500 ppm of

BIOBANᵀᴹ BP-PLUS Preservative.Add as a final step

before packing into bulk

or sales packs.Inks and Fountain

SolutionsTo inhibit bacterial growth

during the storage and use

of water-based printing inks and

fountain solutions.For in-can applications dose

100 500 ppm of BIOBANᵀᴹ BP-PLUS

Preservative. In fountain reservoir

applications use 25-100 ppm of

BIOBANᵀᴹ BP-PLUS Preservative.For in-can preservation, add

as a final step. During use,

shock dose in the fountain

reservoir where there is

adequate flow or agitation.Oil and Gas Fluids To control aerobic and

anaerobic bacteria in oil and

gas-related production.25-200 ppm of BIOBANᵀᴹ BP-

PLUS Preservative in oil flooding/

injection water, enhanced oil

recovery fluids, produced water,

drilling fluids, workover fluids and

completion fluids, well squeeze

and fracturing fluids.Add at any convenient

point, in the process.Oil and Gas

Transportation

and StorageFor protection against bacterial

growth and microbial-induced

corrosion in pipelines and water

bottoms in tanks.25-200 ppm of Bioban™ BP-

PLUS Preservative for pipeline

maintenance. 50-100 ppm in water

bottoms of tanks.Add directly to

the water phase.Raw Materials To control bacteria in

raw materials.100-500 ppm BIOBANᵀᴹ BP-PLUS

Preservative based on the final

formulation volume.May be added at any time,

but ideally as a final step.Surfactants To control bacteria in

industrial surfactants.100-500 ppm BIOBANᵀᴹ BP-PLUS

Preservative based on the final

formulation volume.May be added at any time,

but ideally as a final step.Consumer, Household

and InstitutionalTo control bacteria in

consumer, household and

institutional products.100-500 ppm BIOBANᵀᴹ BP-PLUS

Preservative based on the

final formulation volume.May be added at any time,

but ideally as a final step.Agricultural Pesticide

ConcentratesTo control bacteria in water-based

agricultural pesticide concentrates.100-500 ppm BIOBANᵀᴹ BP-PLUS

Preservative based on the final

formulation volume.May be added at any time,

but ideally as a final step.Chemical Toilets

DeodorantsTo control odor causing bacteria

in chemical toilet application.100-500 ppm of

BIOBANᵀᴹ BP-PLUS Preservative.Incorporate into the

deodorant concentrate.- Uses

Bioban™ BP-Plus Preservative may be used in the following end-use applications.

Pulp and Paper

Bioban™ BP-Plus Pres may be used for the control of slime-forming bacteria in paper mill process water and bulk pulp. It can be added into the hydropulper, machine chest or stock check. The correct dose of active ingredient for these applications is 10-250 ppm Bioban™ BP-Plus Pres in paper mill process water and 50-250 ppm Bioban™ BP-Plus Pres in bulk pulp.Water Treatment

Bioban™ BP-Plus Pres may be used to control slime-forming bacteria in recirculating water cooling towers, evaporative condensers, industrial process water, and air scrubber, air conditioner and humidifier systems. BIOBANᵀᴹ BP-PLUS Preservative may be dosed directly into the sump or basin at any point where there is adequate agitation to ensure dissolution. The correct dose range of active ingredient is 25-100 ppm Bioban™ BP-Plus Pres.

Absorbent Clays, Corn Cobs and Ground Wood

Bioban™ BP-Plus Pres may be used in absorbent clays, corn cobs and ground wood to inhibit the growth of odor-causing bacteria. The suggested application rate of Bioban™ BP-Plus Pres in clay, corn cob, and ground wood applications, is 25-200 ppm impregnated on the materials generally in a prepared solution.

Adhesives

Bioban™ BP-Plus Pres is effective and compatible in most water-based adhesive formulations including dextrin, clay and polyvinyl acetate containing systems. A typical treatment level of 100-5000 ppm is recommended.Starch and Pigment Slurries

Bioban™ BP-Plus Pres is useful for the control of bacterial growth in aqueous system such as starch suspensions and pigment slurries. Add Bioban™ BP-Plus Pres at, or close to, the end of the manufacturing process, either as a solid or pre-dispersed in a quantity of the process water. Bioban™ BP-Plus Pres should be dosed at 100-500 ppm.

Paints, Latex, and Antifoam Emulsion Systems

Bioban™ BP-Plus Pres provides in-can preservation and prevents bacterial spoilage during shelf-life storage of styrene- acrylic, polyvinyl acetate and other latex emulsion concentrates and latex emulsion based paints. It is also effective for the preservation of silicone and other antifoam emulsion systems. Bioban™ BP-Plus Pres can be added at any convenient point during the manufacturing process. Ideally, it should be added as a final step just prior to packing the product into bulk or sales packs. Bioban™ BP-Plus Pres should be dosed at 100-500 ppm.

Water-Based Printing Inks and Fountain Solutions

Bioban™ BP-Plus Pres can inhibit the growth of spoilage bacteria during the storage and use of water-based printing inks and fountain solutions. For in-can preservation of inks, Bioban™ BP-Plus Pres should be added as a final step and should be dosed at 100-500 ppm. To control bacterial spoilage during the use of fountain solutions, Bioban™ BP-Plus Pres should be shock dosed at a suitable point in the fountain reservoir where there is adequate flow or agitation to insure quick dissolution. Bioban™ BP-Plus Pres may be shock dosed once or twice weekly as a normal routine. Where conditions indicate, more frequent shock dosing may be required. In fountain solutions, Bioban™ BP-Plus Pres should be shock dosed at 25-100 ppm.

Oil Production

Bioban™ BP-Plus Pres may be used to control aerobic and anaerobic bacteria, especially sulfate-reducing bacteria, in oil and gas-related production. Bioban™ BP-PLUS Preservative may be dosed at any convenient point in the process. The dose rate for oil flooding/injection waters, enhanced oil recovery fluids, produced water, drilling fluids, fracturing fluids and workover and completion fluids is 50-100 ppm Bioban™ BP-Plus Pres. The dose rate of active ingredient for well squeeze fluids and fracturing fluids is 25-200 ppm.

Oil and Gas Transportation and Storage

Bioban™ BP-Plus Pres may be used to control aerobic and anaerobic bacteria that contribute to corrosion in pipeline maintenance and water bottoms in oil or transportation tanks. The dose range for water bottom in oil or transportation tanks is 50-100 ppm in the aqueous phase. For pipeline maintenance the dose range is 25-200 ppm.

Properties

- Physical Form

- Soluble In

- Appearance

- Free flowing powder

- Insoluble in

- Aliphatic hydrocarbons

- Soluble in

- Glycols and other polyols, Water and lower alcohols

- Physical Properties

Value Units Test Method / Conditions Bulk Density 1.2 g/cc - Melting Point approx. 130 °C - pH Value (of 1% Solution at 20°C) 05 - 07 - - Purity min. 99 wt% - Water Content max. 0.5 wt% - - Microbiological Values

Value Units Test Method / Conditions Enterobacter aerogenes 25 ppm - Escherichia coli 12.5 - 50 ppm - Klebsiella pneumoniae 25 ppm - Legionella pneumophilia serotype 25 - 50 ppm - Pseudomonas aeruginosa 12.5 - 50 ppm - Pseudomonas cepacia 25 ppm - Pseudomonas fluorescens 25 ppm - Pseudomonas putida 25 ppm - Pseudomonas stutzeri 25 ppm - Staphylococcus Aureus Count 12.5 - 30 ppm - Staphylococcus epidermidis 50 ppm -

Technical Details & Test Data

- Formulating Considerations

The active ingredient in Bioban™ BP-Plus Pres, bronopol, is compatible with a range of materials used in water treatment, pulp and paper and other process applications. The materials include compounds such as scale inhibitors, pitch stabilizers, sizing agents, retention aids, flocculants and other biocides. However, strong reducing agents such as bisulfite (>50 ppm), oxidizing agents such as free residual chlorine (>5 ppm) and secondary amines should be avoided. It is also recommended that Bioban™ BP-Plus Pres not be subjected to temperatures greater than 40°C/104°F in order to avoid its decomposition. For formulations that will be repeatedly exposed to microbial challenges during storage and use (user opening and closing product container) the optimum pH range of use is below 8; however, products that are greater than pH 8 can still be preserved with Bioban™ BP-Plus Pres. Testing should be performed to confirm that Bioban™ BP-Plus Pres Preservative meets the preservation requirements outlined for the product. Bioban™ BP-Plus Pres can be used alone or in combin- ation with other biocides. The use of multiple preservatives provides additional protection against bacterial and fungal spoilage. In addition, combination systems are often more cost effective. Multiple biocide combinations help prevent the establishment of populations of organisms resistant to a single biocide. Bioban™ BP-Plus Pres can be used with a wide variety of biocides. The most popular combinations are those with 5 chloro-2-methyl-4-isothiazolin-3-one and 2-methyl-4- isothiazolin-3-one (CMIT/MIT) or 1,2-benzisothiazolin-3-one (BIT). The dosage levels of CMIT/MIT, typically 25-30 ppm active ingredient for preservation applications, can be reduced to 7.5 to 15 ppm active ingredient when combined with 100-200 ppm (active ingredient) Bioban™ BP-Plus Pres. The benefits of the combination of these two actives are as follows:

- Synergistic activity has been reported between bronopol and isothiazolinones in both the USA and Japan.

- Pseudomonas efficacy – BIOBANᵀᴹ BP-PLUS Preservative demonstrates excellent efficacy against Pseudomonas, a weakness of isothiazolinone chemistry.

- BIOBANᵀᴹ BP-PLUS Preservative is more effective in the presence of reducing agents as compared to isothiazolinones. In addition, BIOBANᵀᴹ BP-PLUS Preservative can improve the stability of CMIT/MIT in the presence of reducing agents.

Packaging & Availability

Storage & Handling

- Storage And Handling Information

At normal use rates Bioban™ BP-Plus Pres is compatible with a wide range of metals. However, the solid or its concentrated solutions can be corrosive to some metals if left in contact for prolonged periods. Care must be taken, therefore, to wipe up and/or wash down all spills where these may lead to prolonged contact with metals. Store the product in its original container, tightly closed in a safe place away from foodstuffs. Wash out the empty container thoroughly and dispose of safely. Minor spillages may be flushed away with plenty of water. Major spillages must be treated with a suitable absorbent carrier which may then be swept up and contained for disposal in accordance with local requirements.