Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Manufactured By

- CASE Ingredients Functions

- Cleaning Ingredients Functions

- Fluids & Lubricants Functions

- Industrial Additives Functions

- Molecular formula

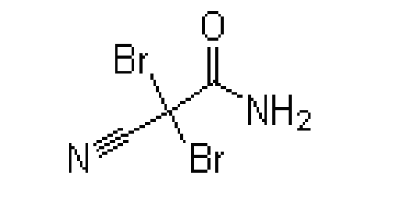

- C₃H₂Br₂N₂O

- Technologies

- Product Families

- Chemical Structure

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Fluids & Lubricants Features

- HII Features

- Industrial Additives Features

- Product Benefits

• Low environmental impact

• Fast acting microbiocide

• Rapid decomposition in aquatic environments with only carbon dioxide,ammonia and bromide ions remaining as end products

• Chlorine compatible

• Completely miscible with water and easily dispersed upon introduction into your system

• Broad spectrum microbiocide, effectively controlling bacteria, yeast, fungi and algae

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Fluids & Lubricants Type

- Adhesive & Sealant End Applications

- Coating End Applications

- Fluids & Lubricants End Use

- Home Care Applications

- I&I Cleaning Applications

- Industrial Additives End Use

- Product Application

Bionix® DB20 can be dosed directly either by open pouring (not recommended for cooling water treatment) or by metered pump either intermittently or on a continuous basis. Bionix® DB20 is best added after any heating stage or when the product has cooled below 40°C. This product is not registered for the use in the State of California.

Water treatment

• Air washers and industrial /recirculating cooling water, publicly-owned treatment works to control coliform and otherbacteria, brewery pasteurizer water, non-potable reverse osmosis systems.

Paper mills

• Pulp, paper mills and paper mills process water systems. Typical addition points are the beaters, jordan inlet ordiskharge, broke chests, furnish chests, savealls and/or white-water tanks.

General preservative

• This product is used to reduce contamination in raw materials and/or products such as: aqueous paints and coatings, polymers, slurries, adhesives, latex and resin emulsions, metalworking fluids, sizing, caulk, process water, along with specialty industrial products including: inks, polishes, waxs, detergents and cleansers.

Equipment cleaning• This product kills microorganisms present in solution or growing on the surfaces of process equipment such as reaction vessels, storage tanks and containers, piping and hoses.

Oil/gas production

• Oilfield and petrochemical systems, enhanced oil recovery systems and fracturing fluids.

Properties

- Physical Form

- Appearance

- Clear, yellow to amber

- Soluble in

- Water (at 20°C)

- Physical Properties

Value Units Test Method / Conditions Vapour Pressure (at 25°C) 18.9 mmHg - Specific Gravity (at 25°C) 1.25 - - Freezing Point -34 °C - Boiling Point 70 °C - pH Value (at 25°C) 2.83 - - Molecular Weight 242 - - - CFR Clearances

21 CFR 175.105 Adhesives 21 CFR 176.170 Cleared for use as antimicrobial agent in pigment and filler slurries used in manufacture of paper and paperboard (max. 500ppm product). Cleared for use in components of paper and paperboard in contact with aqueous and fatty foods (max. 500ppm product)

21 CFR 176.180 Components of Paper and Paperboard in contact with dry food (max. 500 ppm product)

21 CFR 176.300 Slimicides (max. 0. 1lb product/ton dry wt. fiber)

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Packaging & Availability

Storage & Handling

- Storage Information

• Product must be stored in closed, but vented, containers in an area with good general ventilation and out of direct sunlight to prevent build up of vapors over time. Product must not be stored at temperatures greater than 35°C. Avoid adiabatic conditions in pumps which have caused accidents; CO₂ evolution and pressure release. Aqueous solutions in plastic containers should not be left in direct sunlight.

• Always wear personal protective equipment (PPE) when handling Bionix® DB20. While the selection of PPE depends on the task to be performed, the environment and the engineering controls in place, the following is the minimum PPE to be worn when handling containers of the product: splash proof chemical goggles, chemical resistant gloves which extend about the wrist, long sleeve shirt and long pants, socks and chemical resistant footwear.