Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Manufactured By

- CASE Ingredients Functions

- Fluids & Lubricants Functions

- Industrial Additives Functions

- Plastics & Elastomers Functions

- Molecular formula

- C₃H₈O₂

- Technologies

- Product Families

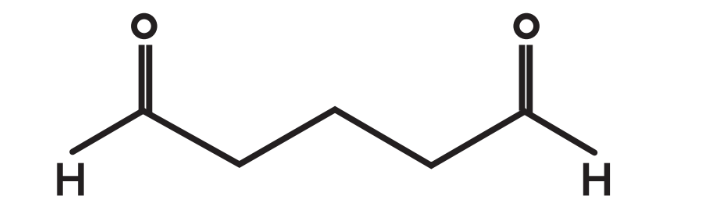

- Chemical Structure

Features & Benefits

- Labeling Claims

- Industrial Additives Features

- Product Benefits

• Broad spectrum antimicrobial

• Functional over a broad pH and temperature range

• Fast-acting

• Does not contain or release formaldehyde

• Compatible with commonly used “wet-end” additives

• Compatible with anionic, nonionic and cationic dispersant’s

• Not affected by the presence of hard water

• Low in toxicity and easy to handle

• Can be diluted or deactivated easily

• Contains no heavy metals

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Compatible Substrates & Surfaces

- Coating End Applications

- Fluids & Lubricants End Use

- Industrial Additives End Use

- Product Application

Bionix® GA50 can be dosed directly either by open pouring (not approved for cooling water treatment) or by metered pump. Bionix® GA50 is best added after any heating stage or when the product has cooled below 40°C. Not for the control of algae in the State of California.

Water treatment

• Air washers and industrial scrubbing systems/recirculating cooling and process water, service water and auxiliary systems, heat transfer systems, industrial wastewater systems, beet sugar mills and beet sugar mill process water systems

Paper mills

• Paper mills and paper mills process water systems, pigments and filler slurries for paper and paperboard, water based coatings for paper and paperboard

General preservative

• Non-food contact for industrial, institutional and consumer non-food contact products, mineral slurries, paints, plastics, pigments, lattices, printing inks, laundry detergents, cleaning products, concentrates, concrete admixtures, reverse osmosis membranes water based conveyor lubricants, preservative for concentrates. Food contact for preservation of food contact adhesives and minerals slurries used in papermaking.

Oil/gas production

• Water floods, drilling, completion and workover fluids, packer fluids, oil products and transmission pipelines and systems, gas production and transmission pipelines and systems, gas storage wells and systems, hydrotesting, pipeline pigging and scraping operations, injections waste fluids.

Properties

- Appearance

- Colorless to light yellow, transparent liquid

- Miscible in

- Water

- Physical Properties

Value Units Test Method / Conditions Flash Point min. 302 °F - Density 9.42 - - Specific Gravity 1.13 - - Pour Point -18 °C - Boiling Point 100.5 °C - pH Value 3.0 - 5.0 - - Molecular Weight 100 - - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Odor Pungent - - Molecular Formula & Weight Solution 0.0 - - Decomposition Temperature 110 °C - Specific Gravity (Water = 1) 1.08 - 1.18 - - Flash Point 302 °F Closed cup Boiling Point 101 °C - Melting Point -18 °C - pH Value 3.0 - 5.0 - - Appearance Colorless to yellow Liquid - - Physical Form Liquid - - Soluble in Water - - - CFR Clearances

21CFR 172.230 Cleared for use as a cross linking agent

21CFR 173.320 Chemicals for Controlling Microorganisms in Beet-Sugar Mills (max. 250ppm active)

21 CFR 173.357 Fixing agent in the immobilization of glucose isomerase enzyme preparations or use in manufacture of high fructose corn syrup

21 CFR 175.105 Adhesives 21 CFR 176.170 Cleared for use as antimicrobial agent in pigment and filler slurries used in manufacture of paper and paperboard (max. 300ppm active)

21 CFR 176.180 Components of Paper and Paperboard in contact with dry food (max. 300 ppm active)

21 CFR 176.300 Slimicides

Regulatory & Compliance

Packaging & Availability

Storage & Handling

- Storage Information

• Under proper conditions, aqueous glutaraldehyde solutions may be stored for extended periods of time with no adverse effects. The material should be stored at or below room temperature whenever possible in order to minimize decomposition. Glutaraldehyde solutions show no change in concentration after one year storage at 25°C and 37°C.

• Handle Bionix® GA50 in well ventilated areas and wear appropriate protective equipment for the task. At a minimum, this includes proper gloves, splash-proof chemical goggles or both safety glasses with side shields and a wrap-around full-face shield, coveralls and boots.