Enhanced TDS

Identification & Functionality

- INCI Name

- Manufactured By

- Cosmetic Ingredients Functions

- Technologies

- Product Families

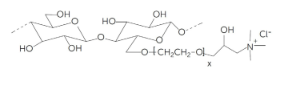

- Chemical Structure

Celquat® SC-240C polymer chemistry

Features & Benefits

- Benefit Claims

- Labeling Claims

- Key Features

- Substantive to hair and skin

- Surfactant compatibility

- Clarity

- Lubricity

- Imparts smooth, rich feel to hair and skin

- Forms clear aqueous solutions and non-tacky continuous films

- Improves wet combability

- Improves gloss and anti-static properties on hair

Applications & Uses

- Markets

- Applications

- Application Format

- Bath & Shower Applications

- Hair Care Applications

- Skin Care Applications

- Use Level

- 0.1 - 0.5% (cleansing applications)

- Product Applications

Celquat® SC-240C polymer has excellent conditioning properties and can be used in a range of hair and skin applications including shampoos, conditioners, body and facial washes, cleansers, styling aids, and creams and lotions.

- Formulation Guidelines

The choice of the appropriate Celquat conditioning polymer to use may depend on the end use. The high viscosity Celquat® SC-240C polymer is best suited for thicker pour out cleansing products, creams, and gels. Other Celquat polymers may be better suited for use in actuated products such as mousses and spritzes, as well as lower viscosity shampoo and pour out products.

Solubility

The Celquat® SC-240C polymer is water soluble. For optimal results, prepare the Celquat polymer solution as a separate phase. Slowly sift the powder into water while stirring. Sifting slowly will avoid the formation of fisheyes and gels. Heat and moderate agitation will increase the solubility rate of the polymer. The polymer is completely hydrated when the solution is clear and there are no insolubles present. Complete hydration is important to ensure homogeneity, viscosity stability, formulation stability, and clarity.

Surfactant systems containing the Celquat® SC-240C polymer can easily be prepared with the fully hydrated Celquat solutions (incompatibilities can result if the Celquat polymer is added directly to the surfactant solutions). The preferred method is to slowly add the surfactants to the fully hydrated Celquat® SC-240C polymer solution. Add the nonionic and amphoteric surfactants first and then add the anionic surfactants. Continue mixing until uniform, and then add the balance of ingredients. It is also possible to add a hydrated Celquat® SC-240C polymer pre-mix solution to the main batch with good agitation.

Celquat® SC-240C polymer is not soluble in such alcohols as ethanol and isopropanol. It can tolerate up to 65% alcohol as a diluent. To incorporate alcohol, solubilize the polymer in a water/alcohol blend or add alcohol to an aqueous polymer solution. At 2% polymer by weight, the Celquat® SC-240C polymer will thicken a 65% alcohol solution to a viscosity of approximately 10,000 cps (spindle #5, 50 rpm, 25°C).

pH stability

Solutions of the Celquat® SC-240C polymer are subject to chemical hydrolysis at extreme pH. For optimum stability, a pH range of 4 to 8 is recommended.

Thickening

Certain formulations based on the Celquat® SC-240C polymer may require thickening to improve their application or use. This polymer can tolerate electrolytes added to build viscosity of concentrated surfactant systems. Other materials can also be used to control viscosity. Commonly used cellulosic type thickeners are effective in raising the solution viscosity, including hydroxyethyl cellulose and hydroxypropyl methylcellulose. Blending with the higher viscosity Celquat® SC-240C polymer can build viscosity. Finally, effective associative thickeners can raise the viscosity of solutions containing the Celquat® SC-240C conditioning polymer can be used.

Preservation

Aqueous solutions of the Celquat® SC-240C polymer are subject to bacteriological growth and enzyme catalyzed degradation. Preservatives suggested for consideration are DMDM hydantoin, methyl p-hydroxybenzoate, propyl p-hydroxybenzoate, Germall® 115 and 2 nitro-2 bromo-1,3 propanediol. The presence of alcohol will also minimize bacteriological growth.

Properties

- Physical Form

- Soluble In

- Typical Properties

Value Units Test Method / Conditions Application pH Range 4 - 8 - - Viscosity (spindle #5, 50 rpm, 25°C) 10000 cPs - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Dust Deflagration Index 36 m.b/s - Dust Explosion Class St1 - - Bulk Density 500 kg/m³ - Lower Explosion Limit 30000 mg/m³ - Flammability (Solid, Gas) Not classified as a flammability hazard - - pH Value (at 1 % solution) 5 - 8 - - Soluble in Water - - - Compatibility

Surfactant

The Celquat® SC-240C polymer is an ideal way of adding conditioning functionality to a shampoo. The polymer was developed to be compatible with a wide variety of anionic, amphoteric, and non-ionic surfactants including:- Sodium Lauryl Sulfate

- Ammonium Lauryl Sulfate

- Sodium Laureth Sulfate

- Ammonium Laureth Sulfate

- Cocamidopropyl Betaine

- PEG-80 Sorbitan Laurate

- Sodium Lauroamphoacetate

- Olefin Sulfonate

- Cocamide MEA

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Performance Properties

Substantivity

The cationic charge on the Celquat SC-240C polymer makes it substantive to keratinous substrates such as hair and skin.

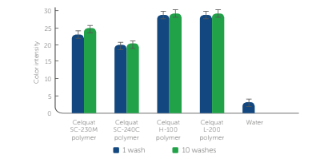

The substantivity of the Celquat SC-240C polymer has been defined using the Lumicrease Dye Test. In this experiment, dyeing wool swatches with an anionic polyazo sulfonate dye after they have been treated with the cationic polymer quantifies deposition of cationic conditioning polymers. Wool is similar to human hair and skin in adsorptive and charge properties and can be used as an efficient substitute substrate for hair testing. The dye is attracted to the deposited cationic polymer. A colorimeter is used to measure the degree of adsorption on each sample via intensity of the dye. The swatches are tested for deposition after 1 wash (1) and 10 washes (10). The 1 wash data is indicative of substantivity, and a significantly higher value for the 10 wash reading over the 1 wash reading is indicative of build-up.

As is in the graph below, Celquat SC-240C polymer is significantly less substantive than the Celquat L-200, Celquat H-100 and Celquat SC-230M polymers. The moderate substantivity of the Celquat SC-240C polymer is particularly useful in light conditioning systems such as baby and kids products. The data below also shows that this polymer does not build-up on the substrate during repeated washings.

Substantivity of Celquat conditioning polymers

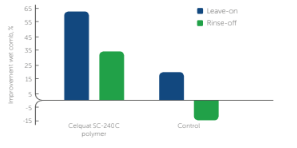

Wet comb performance

The conditioning properties for the Celquat SC-240C polymer are readily seen in wet comb force reduction studies. Leave- in and rinse-off wet combing properties were tested on damaged hair using the following model shampoo system:

Ingredient % Celquat polymer 0.5 Ammonium Laureth Sulfate 10.5 Cocamidopropyl Betaine 3.3 Cocamide MEA 0.5 Preservative 0.4 Ammonium Chloride 0.2 Water up to 100 The wet combing studies were performed using the Sintech MTS Synergie 200 tensile tester in a constant temperature humidity room. The reported values are the average data from three sets of tresses. Each tress set represents averaged data for three replicates. The results below show that the Celquat SC-240C polymer significantly reduces wet comb force in both the rinse-off and leave-on applications.

Wet comb force reduction

Packaging & Availability

- Country Availability

- Packaging Information

Celquat SC-240C polymer is one member of the Celquat family of polymers that are water soluble quaternary cellulose derivatives. Other Celquat polymers offered include:

- Celquat H-100 polymer, Polyquaternium-4

- Celquat L-200 polymer, Polyquaternium-4

- Celquat SC-230M polymer, Polyquaternium-10

Celquat SC-240C polymer is a low viscosity quaternized conditioning polymer. It is prepared by reacting a trimethyl ammonium substituted epoxide onto the hydroxyl groups of the hydroxyethyl cellulose backbone. This reaction yields a polymer with a dispersed series of cationic charges along the polymer chain. This polymer is a lower viscosity variant of its chemically similar sister product, the Celquat SC-230M polymer.

Storage & Handling

- Storage Information

Celquat SC-240C polymer product should be stored in a cool, dry location away from heat, sparks or fire. When not in use, the container should be kept closed to prevent moisture and dust contamination. We recommend that normal precautions be taken to avoid ingestion or contact with eyes. Respiratory protection should be used to avoid dust inhalation. Good industrial hygiene practices should be followed. Please read the MSDS before using this or any other chemical.