Enhanced TDS

Identification & Functionality

- INCI Name

- Manufactured By

- Cosmetic Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Benefit Claims

- Product Benefits

Features Benefits Film-formation Proven water resistance and SPF retention at low use levels

Resistant to rub offAesthetics Lightweight feel during and after application Low viscosity, polymer emulsion Easy to incorporate into emulsion sunscreens and low viscosity pump spray formulations Globally approved Useful in a wide range of systems

Suitable for use in all regions

Applications & Uses

- Markets

- Applications

- Application Format

- Skin Care Applications

- Sun Care Applications

- Use Level

- 1.0 - 5.0% active (creams and lotions), 1.0 - 20.0% active (color cosmetics), 2.22 - 5.0% active (tinted sunscreens), 2.22 - 3.0% active (spf daily wear moisturizer), 2.22 - 5.0% active (sun protection)

- Application Information

- High performance sport SPF 50+ lotions

- Mineral sunscreen formulations

- Daily wear moisturizer with SPF

- Color cosmetics

- Face, body, hand and foot creams and lotions

- Formulation Guidelines

- Supplied as a low viscosity liquid aqueous emulsion, Dermacryl® X film-forming polymer is easily dispersed in the water phase of oil-in-water emulsions and is easy to work with in lab and large-scale manufacturing settings.

- Dermacryl® X polymer can either be added into the water phase prior to forming the emulsion or post added after the emulsion is formed.

- It requires no heat or neutralization and can be used in either hot or cold emulsification processes.

- The material can be used at typical sunscreen formulation pH ranging from pH = 5 to 8.

- Lasting protection

- Dermacryl® X polymer provides effective and lasting film formation, enabling the formulation of reliable, high SPF systems.

- This polymer is well suited for high performance products that depend on excellent durability in both rub and global water resistance test methods.

Properties

- Insoluble in

- Di/cyclomethicone, 1,2 propanediol

- Compatibility

Sunscreen actives:

- Dermacryl® X film-forming polymer performs well in the typical sunscreen formulations and has excellent compatibility with commonly used sunscreen actives, including Ethylhexyl

- Salicylate (Octisalate), Homosalate, Octocrylene, Avobenzone, Ethylhexyl Methoxycinnamate (Octinoxate), Benzophenone-3 (Oxybenzone), Titanium Dioxide and Zinc Oxide.

Other:

- Dermacryl® X film-forming polymer is also compatible with a wide range of commonly used cosmetic ingredients:

- Carbomer, Xanthan Gum, Acrylates/C10-30 Alkyl Acrylate Crosspolymer, and other frequently used thickeners and polymeric emulsifiers.

- It is recommended that Dermacryl X polymer be incorporated after emulsification and neutralization has taken place when formulations include Acrylates/C10-30 Alkyl Acrylate

- Crosspolymer at levels above 0.3%.

Technical Details & Test Data

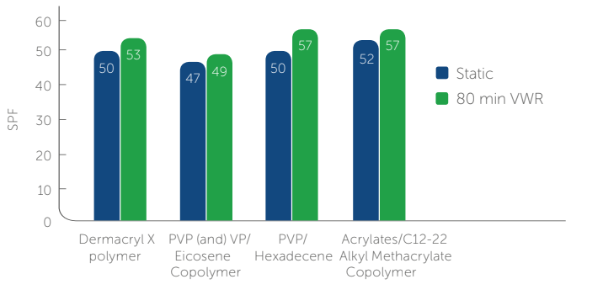

- Dermacryl® X vs competitive benchmarks

In-vivo water resistance

FDA method, 5 panelist screener

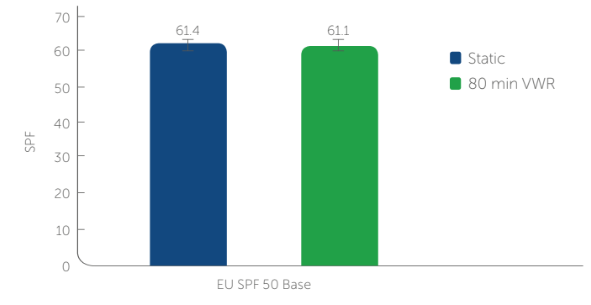

- Dermacryl X in EU base SPF 50 system

In-vivo water resistance

5 panelist screener ISO 24444:2010 and COLIPA guidelines

Packaging & Availability

Storage & Handling

- Shelf Life

- 12 months

- Storage Information

- Dermacryl X polymer should be protected from freezing.

- Avoid extreme temperatures during storage.

- Good industrial hygiene practices should be followed when working with this polymer.