Enhanced TDS

Identification & Functionality

- Chemical Family

- Manufactured By

- CASE Ingredients Functions

- Industrial Additives Functions

- Technologies

- Product Families

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Coating End Applications

- Industrial Additives End Use

- Use Level

- 5 - 10%, 2 - 4%, 30 - 60%

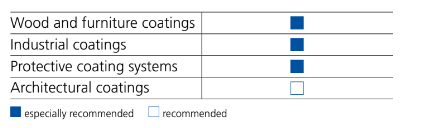

- Coatings Industry Application

Special Features and Benefits:

- The additive is used to produce highly concentrated matting agent pastes.

- Such pastes are fluid, stable upon storage, easy to utilize, and capable of being automatically dosed into the system.

- These matting agent pastes can also be post-added to adjust the degree of matting.

- The gloss reduction of matting agent pastes produced with DISPERBYK® 103 may be lower than that of matting agents utilizing dry incorporation.

Recommended Use:

Incorporation and Processing Instructions:

- For optimum performance, the additive must be incorporated into the millbase.

- Prepare paste resin, mix with the solvent and the additive, then add the matting agent.

- Example: Grinding resin (60% solution), 30 parts;DISPERBYK® 103, 12 parts; solvent, 40 parts; matting agent, 18 parts.

Properties

- Typical Properties

Value Units Test Method / Conditions Flash Point 47 °C - Solvents Methoxypropylacetate - - Non-Volatile Matter (10 min, at 150°C) 40 % - Density (at 20°C) 1.06 g/ml - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Ignition Temperature min. 392.00 °F DIN 51794 Miscible In Water - - Density (at 68°F) 1.06 g/cc 4 (Oscillating U-tube, at 20°C) Lower Explosion Limit 1.5 %V - Explosion Limits (Upper) 7 %V - Flash Point 116.6 °F 48 (Abel-Pensky) Vapor Pressure (at 68°F) 3 hPa Derived Initial Boiling Point 294.8 °F Derived Melting Point max. 32 °F Derived pH Value (at 20°C, 10% Concentration) 6 - - Odor Ester-like - - Appearance White liquid - - - Compatibility

- Solution of a copolymer with filler affinic groups

Packaging & Availability

Storage & Handling

- Storage and Transportation

- At temperatures below 10 °C, DISPERBYK® 103 has a tendency to cloud and separate.

- In this case, please heat the product to a temperature of approx. 35 °C and then stir.