Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Manufactured By

- CASE Ingredients Functions

- Fluids & Lubricants Functions

- Industrial Additives Functions

- Molecular formula

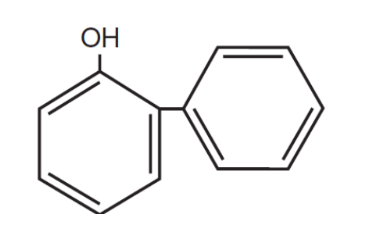

- C₆H₄(C₆H₅) OH

- Technologies

- Product Families

- Chemical Structure

Applications & Uses

- Markets

- Applications

- Fluids & Lubricants Type

- Adhesive & Sealant End Applications

- Fluids & Lubricants End Use

- Industrial Additives End Use

- Key Applications

Glues and Adhesives To protect from deterioration during manufacture, storage and service life Glues: Bone/plant - 0.1 - 0.15%

Leather, Skin & Fish - 0.15 - 0.4%

Gelatin based - 0.15 - 0.3%

Starch based liquid - 0.1 - 0.25%

Starch based solid - 0.15 - 1.0%

Albumin containing - 0.2 - 0.4%

Adhesives: cellulose/dextrin - 0.1 - 0.3%

Polymer dispersion based - 0.1 - 0.3%

Casein containing - 0.2 - 0.4%Add to organic portion of the ingredients, mix then add to the formulation

Gaskets To preserve felt gaskets 1% by wt. of organic solvent Saturate felt with solution of DOWICIDE 1E Antimicrobial in a volatile solvent such as alcohol or Stoddard solvent.

Concrete Admixtures To control the growth of fungi and bacteria in concrete admixtures 0.01 - 0.6% by weight of admixture Add at a suitable point during the manufacture of the admixture. Conversion to a water dilutable alkaline concentrate, using sodium hydroxide, is recommended.

Slurries To control the growth of fungi and bacteria in aqueous based slurries and dispersed pigments, such as clay, calcium carbonate, kaolin and other filler suspensions 0.05 - 0.9% by weight of slurry Add at a suitable pint during the manufacture, container loading/filling or shipment of the slurry. If needed, add caustic to make a water dilutable alkaline concentrate.

Ceramics To prevent decomposition of ceramic glazes and clay slips 0.05 - 0.1% by wt. of glaze or slip formulation Add to ingredients of formulation as they are charged into ball mill.

Metalworking Fluids To prevent de-composition of fluids prepared from water-emulsifiable oil concentrates 0.1 - 1.5% by wt. of diluted concentrate Add to water-emulsifiable oil concentrate during formulating. process.

Leather To impart temporary mold resistance to shoe liners, hat bands, gloves, etc. 1.5% by wt. of leather Apply from petroleum and vegetable oil formulation.

Properties

- Physical Form

- Soluble In

- Sales Specifications

Value Units Test Method / Conditions Active Ingredient (o-phenylphenol) 99 % - Boiling Point 286 °C - Bulk Density 35 - 41 lb/ft³ - CARBOWAX PEG400 180 - - Ethanol Content (95%, F2B) 580 - - Ethylene Glycol Content 140 - - Fire Point 149 °C Cleveland Open-Cup Flash Point 124 °C Cleveland Open-Cup Freezing Point 57 °C - Glycol Ether Content (DOWANOL PM) 420 - - Inert Ingredients 1 % - Isopropanol Content 460 - - Methanol Content 870 - - Molecular Weight 170.2 - - Polyglycol P1200 Content 140 - - Polyglycol P400 Content 180 - - Propylene Glycol Content 280 - - Specific Gravity (at 25°C) 1.2 - - Vapor Pressure (at 100°C) 1.13 hPa - Vapor Pressure (at 140°C) 7 - - Vapor Pressure (at 20°C) 0.0017 mmHg - Vapor Pressure (at 50°C) 0.0326 mmHg - Water (at 25°C) 0.08 - - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Auto Ignition Tempertaure 530 °C - Boiling Point (at 760 mmHg) 286 °C - Color Off - white - - Flammability (Solid, Gas) May form combustible dust concentrations in air - - Flash Point 124 °C Closed cup, Setaflash Closed Cup, ASTM D3828 Lower Explosion Limit (Vapour Literature) 0.5 vol% - Melting Point 56.9 °C - Odor Mild Phenolic - - Partition Coefficient (N - octanol/water, Log Pow) 3.09 Upper Explosion Limit (Vapour Literature) 9.5 vol% - Vapor Pressure (at 25°C) 0.00162 mmHg - Physical State Flakes - Solubility Data

Value Units Test Method / Conditions CARBOWAX PEG400 Solubility (at 25°C) 180 g/100g - DOWANOL* PM glycol ether. Solubility (at 25°C) 420 g/100g - Ethanol 95%, F2B Solubility (at 25°C) 580 g/100g - Ethylene Glycol Solubility (at 25°C) 140 g/100g - Isopropanol Solubility (at 25°C) 460 g/100g - Methanol Solubility (at 25°C) 870 g/100g - Polyglycol P1200 Solubility (at 25°C) 140 g/100g - Polyglycol P400 Solubility (at 25°C) 180 g/100g - Propylene Glycol Solubility (at 25°C) 280 g/100g - Water Solubility (at 25°C) 0.08 g/100g - Water Solubility (at 60°C) 0.16 g/100g -

Safety & Health

- Safety Information

Toxicological Properties

DOWICIDE 1E Antimicrobial is an eye irritant. The product is capable of causing moderate to severe conjunctival redness, moderate to severe swelling, slight to moderate iritis and slight to moderate corneal injury. It is neither a primary skin irritant nor a skin sensitizer. It is not absorbed through the skin in toxic amounts. The dusts are irritating to the upper respiratory tract.

Handling Precautions for Cleaning Up Spills or When Gross Contact is Likely

- Eyes - Wear goggles or face shield when handling.

- Skin - Avoid skin contact. Wear protective clothing as required by circumstances to prevent skin contact.

- Inhalation - Avoid breathing dusts. If dusty atmospheres are encountered, wear a NIOSH-approved dust/mist respirator. Airborne concentrations should be maintained to levels below the recommended DuPont Industrial Hygiene Guide of 1 mg/m³

First Aid Measures

- Eye Contact - Contaminated eyes should be washed promptly and thoroughly with flowing water for at least 30 minutes. Medical attention should be obtained.

- Skin Contact – Immediately wash any size exposure with non- abrasive soap and large quantities of water for 30 minutes while removing contaminated clothing and shoes. Items that cannot be decontaminated, such as shoes, should be destroyed.

- Inhalation – Anyone experiencing any noticeable ill effects from breathing the dust of this material should be removed to fresh air. Consult a physician.

Packaging & Availability

Storage & Handling

- Handling Information

Handling Precautions for Cleaning Up Spills or When Gross Contact is Likel

Eyes - Wear goggles or face shield when handling. Skin - Avoid skin contact. Wear protective clothing as required by circumstances to prevent skin contact. Inhalation - Avoid breathing dusts. If dusty atmospheres are encountered, wear a NIOSH-approved dust/mist respirator. Airborne concentrations should be maintained to levels below the recommended DuPont Industrial Hygiene Guide of 1 mg/m3