Enhanced TDS

Identification & Functionality

- Chemical Family

- Manufactured By

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Benefits

Because it was developed with the customer in mind, Durastrength® 350 brings a wealth of benefits to compounders and manufacturers such as:

- Durastrength® 350 impact modifier provides superior long-term weather resistance while retaining impact resistance and color retention.

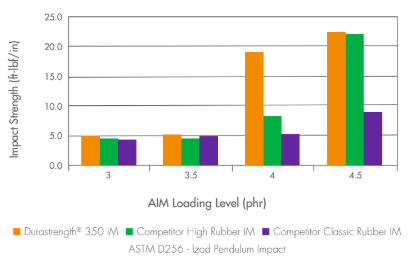

- Durastrength® 350 impact modifier imparts excellent room temperature impact resistance while maintaining industry required low-temperature impact resistance.

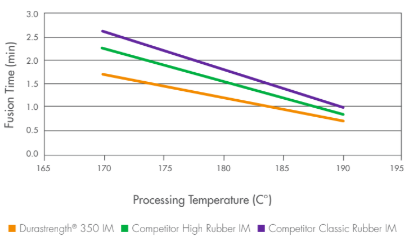

- Durastrength® 350 impact modifier provides a broad process window allowing flexibility in processing temperature and output.

- Durastrength® 350 impact modifier offers faster fusion over competitive acrylic impact modifiers without the need for additional process aids.

Izod Impact (Window Profile Formulation)

Fusion Time Versus Processing Temperature

Applications & Uses

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Suggested Use Levels

- Durastrength® 350 impact modifier is ideally suited for vinyl window profile, siding, fencing, decking, pipe, and conduit. The low melt viscosity and rapid fusion characteristics of Durastrength® 350 impact modifier are also ideal for difficult injection molding applications.

- Durastrength® 350 impact modifier is recommended for use in tin, lead, and mixed-metal stabilized profile applications where enhanced room and cold-temperature impact resistance is required. As with all impact modifiers for PVC, proper formulation is required to develop the proper shear and mixing during extrusion so that impact properties are optimized.

- Prospective customers should evaluate Durastrength® 350 impact modifier in their own laboratories to establish optimum conditions for use in their processes and applications. Arkema’s Technical Service Team is available to discuss your application requirements, provide formulation guidance and laboratory testing as needed.

- Starting Formulation Recommendations

Window Profile PVC Resin (K-65 to K-67) 100.0 phr Methyl Organotin Stabilizer 1.0 - 1.5 Calcium Stearate 1.0 - 1.5 Paraffin/Ester Lubricant 0.8 - 1.5 Oxidized Polyethylene 0.0 - 0.2 Durastrength® 350 Impact Modifier 4.25 - 5.25 Plastistrength® 530 / 550 Process Aid 0.3 - 1.01 Plastistrength® 770 Process Aid 0.2 - 0.5 Calcium Carbonate (0.7 pm)| 3.0 - 8.0 Titanium Dioxide 9.0 - 10.0

Custom Injection Molding

PVC Resin |K-55)| 100.0 phr Butyl Organotin Stabilizer 2.0 - 2.5 Paraffin Wax (165°F mpl 1.0 - 1.5 Calcium Stearate 1.5 - 2.0 Durastrength® 350 Impact Modifier 6.5 - 10.0 Plastistrength® 550 Process Aid 1.5 - 2.01 Plastistrength® 770 Process Aid 0.5 - 1.01 Calcium Carbonate (0.8pm) 0.0 - 5.0 Titanium Dioxide 2.0 - 5.0

Properties

- Physical Form

- Appearance

- White powder

- Physical Properties

Value Units Test Method / Conditions Particle Size on 50 Mesh max. 15 % - Percent Volatile max. 1.2 % - Bulk Density 0.45 g/cc - Specific Gravity 1.1 - - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Insoluble In Water - - Bulk Density 250 - 500 kg/m³ - Auto Ignition Temperature 752 °F - Odor Slightly acrylic - - Appearance White powder - - Physical Form Solid - -