Enhanced TDS

Identification & Functionality

- Chemical Family

- Manufactured By

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

- Product Benefits

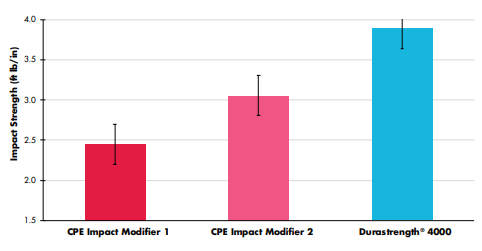

1. Excellent impact resistance that is equivalent to or better than alternative non-acrylic impact modifiers.

Typical Impact Resistance [Izod Impact Performance (Siding Substrate Formulation @ 4.5phr Modifier)]

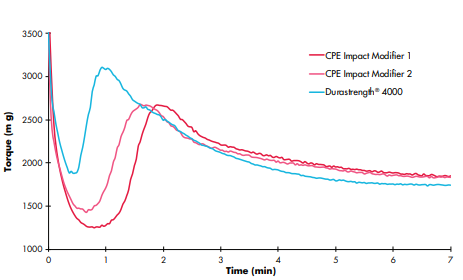

2. Faster fusion than alternative non-acrylic impact modifiers without the need for additional processing aids.

Typical Torque Rheometer Fusion

Torque Rheometer Curves Settings: 175°C, 75 RPM and 100 cc sample size Impact modifiers evaluated at 4.5 phr

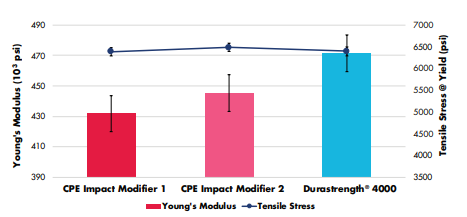

3. Substrate applications utilizing Durastrength® 4000 impact modifier maintain important mechanical properties for final PVC product performance.

Typical Mechanical Property Performance (Tensile Evaluation)

Evaluation followed ASTM D-638 Impact modifiers tested at 4.5 phr

4. Durastrength® 4000 impact modifier has traditional acrylic characteristics such as a low melt viscosity which when employed in a vinyl formulation results in good stability, smooth processing, and high output rates.

Applications & Uses

- Plastics & Elastomers End Uses

- Suggested Use Levels

Durastrength® 4000 impact modifier is recommended for applications requiring impact properties in addition to ease of processing such as siding, fence and deck substrate. As with all impact modifiers for PVC, proper formulation is required to develop the necessary shear and mixing during extrusion so that impact properties are optimized.

Prospective clients should evaluate Durastrength® 4000 impact modifier in their own laboratories to establish optimum conditions for use in their processes and applications. Arkema’s Technical Service Team is available to discuss your application requirements, provide formulation guidance, and laboratory testing as needed.- Typical Starting Formulation Recommendations

Rigid Siding Substrate Use Level (phr) PVC Resin |K-65 to K-67) 100 Butyl Organolin Stabilizer 0.8 - 1.2 Calcium Stearatel 1.0 - 1.5 Paraffin Wax (165 m.p.) 1.0 - 1.5 Oxidized Polyethylene Wax 0.1 - 0.2 Durastrength® 4000 Impact Modifier 4.0 - 5.0 Calcium Carbonate (0.7 um) 10.0 - 20.0 Titanium Dioxide 0.5 - 1.5

Ribbed Pipe Use Level (phr) PVC Resin |K-65 to K-67) 100 Buryl Organotin Stabilizer 0.6 - 0.8 Calcium Stearate 0.6 - 0.8 Paraffin Wax (165 m.p.) 10-1.2 Oxidized Polyethylene Wax 0.1 - 0.2 Durastrength® 4000 Impoct Modifier 3.5 - 4.5 Plastistrongth® Procoss Aid 0.0 - 0.6 Calcium Carbonate (0.7 um] | 4.0 - 6.0 Titanium Dioxide 1.0 - 2.0

Properties

- Physical Form

- Appearance

- White powder

- Physical Properties

Value Units Test Method / Conditions Particle Size on 50 Mesh max. 15 % - Percent Volatile max. 1.2 % - Particle Size max. 15 % - Bulk Density 0.55 g/cc - Specific Gravity 1.47 - - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Insoluble In Water - - - Note

*The mechanical property and rheology property data listed are considered to be typical properties, not specifications.

Regulatory & Compliance

- Chemical Inventories