Enhanced TDS

Identification & Functionality

- Chemical Family

- Manufactured By

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- Materials Features

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers Processing Methods

- Use Level

- max. 25 % (for Bioplastics), max. 40 phr (for PVC)

- Application Information

- Edenol® 2178 US is a polymeric plasticizer based to 100 % on renewable raw materials. It is perfectly suitable for the use in bioplastics such as PLA, PHA or blends thereof. Edenol® 2178 US can be used in conventional processing steps, for example extrusion, injection molding or film blowing.

- PLA or PLA/PHA blends are rather brittle materials. When Edenol® 2178 US is used as a primary plasticizer in these polymer blends, it improves the handling properties such as the elasticity. In PLA, Edenol® 2178 US provides a much better elasticity (elongation at break) compared with a polyadipate plasticizer with similar viscosity. In order to achieve a higher migration resistance, a combination with Edenol® 2192 US is recommended.

- Edenol® 2178 US can also be used in PVC formulations as a plasticizer to increase the renewable content. To avoid exudation the dosage should not exceed 40 phr.

Properties

- Physical Form

- Appearance

- Slightly yellowish liquid

- SDS Physical and Chemical Properties

Value Units Test Method / Conditions Color Slightly yellowish - - Density (at 20°C) 1.04 - 1.08 g/cc - Dynamic Viscosity (20°C) 650 - 750 mPa.s - Flash Point min. 225 °C Open cup Insoluble in Cold water - - Odor Neutral - - Physical State Liquid - - - Test Parameter

Value Units Test Method / Conditions Acid Value 0 - 2.0 mg KOH/g DIN EN ISO 2114 Refractive Index (at 20°C) 1.4575 - 1.4595 - DIN 51423 Viscosity (at 20°C) 650 - 750 mPa.s DIN 53019

Technical Details & Test Data

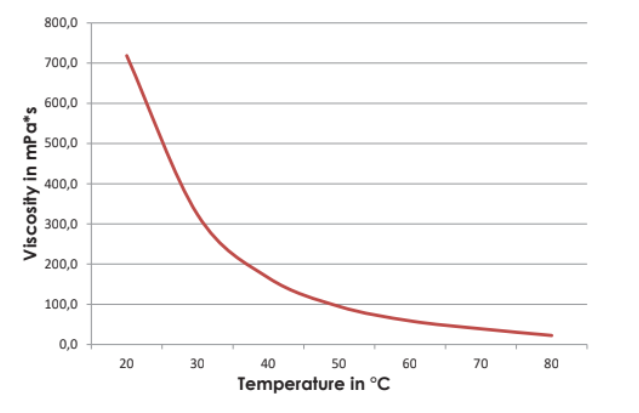

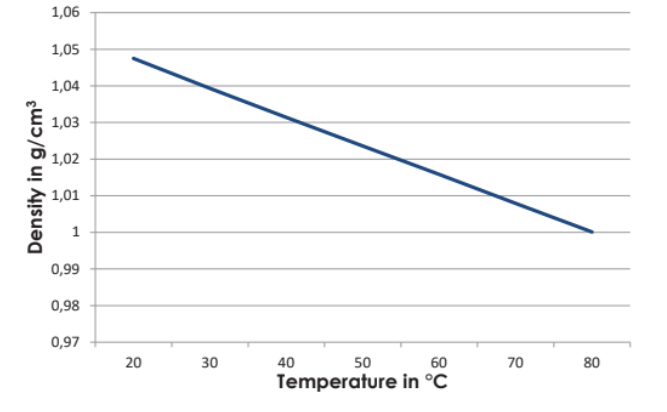

- Viscosity and Density Graph

Viscosity

Density

Packaging & Availability

- Country Availability

- Packaging Type

- Product Packaging

- IBC tote, liquid

- Drum, liquid

Storage & Handling

- Shelf Life

- 24 months

- Storage Conditions

It is recommended to store Edenol® 2178 US at room temperature and to protect the product against the effects of heat and frost. Due to its pour point, the product may deposit and become solid at temperatures below -3 °C. This physical property is specific to the product and will be reversible when heated under mixing. It has no influence on the effectiveness or its application properties. If stored in sealed original packaging, Edenol® 2178 US should be stable for at least 24 months from the date of manufacture.