Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Manufactured By

- CASE Ingredients Functions

- Plastics & Elastomers Functions

- Technologies

- Product Families

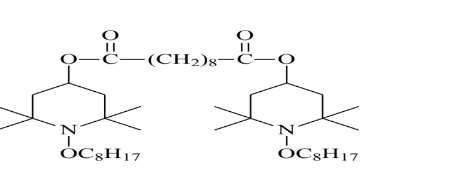

- Chemical Structure

Features & Benefits

- CASE Ingredients Features

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Cure Method

- Coating End Applications

- Advantages

- Low basicity.

- Provide no effect on initial color of substrates.

- Good solubility in most industrial solvents.

- Provide high synergistic effect with UV absorbers.

Properties

- Color (Properties)

- Physical Form

- Appearance

- Slightly yellowish liquid

- Physical Properties

Value Units Test Method / Conditions Density (at 20°C) 0.97 - - Viscosity (at 40°C) 550 - 650 cPs - Viscosity (at 20°C) 2700 - 3300 cPs - - Typical Properties

Value Units Test Method / Conditions Molecular Weight 737 g/mol - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point/Boiling Range min. 350 °C - Color Slightly yellow - - Flash Point 95 - 125 °C - Insoluble in Water - - Melting Point max. - 30 °C - Odor Odorless - - pH Value (1% suspension in water at 20 °C) 3.5 - - Physical Form Liquid - - Relative Density (at 20°C) 0.97 g/cc - Soluble in Solvents - - - Solubility Data

Value Units Test Method / Conditions Water Solubility (at 25°C) max. 0.1 g/100g solvent - 1-Methoxy-2-propylacetate Solubility (at 25°C) min. 50 g/100g solvent - Butyl Acetate Solubility (at 25°C) min. 50 g/100g solvent - Butylcarbitol Solubility (at 25°C) min. 50 g/100g solvent - Methyl Ethyl Ketone Solubility (at 25°C) min. 50 g/100g solvent - Xylene Solubility (at 25°C) min. 50 g/100g solvent -

Regulatory & Compliance

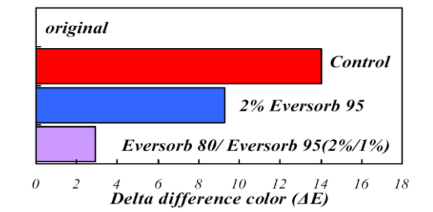

Technical Details & Test Data

- Techical Information

- Resin: Nitrocellulose(NC)

- Model: Q-U-V Accelerated Weathering Tester

- Test Model: ASTM G154-2(QUV with UVB-313 light bulb )

- Test Time: 1000 hours

- Dry Method: Drying 6 hours at room temperature

-

Packaging & Availability

Storage & Handling

- Storage and Handling Information

- Personal equipment for protection is recommended.

- Excess exposure to the product should be avoided.

- Wash thoroughly after handling.

- Eversorb® 95 should be kept in a dry, dark place without any light exposure.