Enhanced TDS

Identification & Functionality

- Chemical Family

- Manufactured By

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Product Advantages

- Easily handing

- Improve gloss retention

- Excellent color retention

- Improve coating durability

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Coating End Applications

Properties

- Physical Form

- Appearance

- Amber to yellowish liquid

- Typical Properties

Value Units Test Method / Conditions Dynamic Viscosity 6000 - 7000 mPa.s - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Boiling Point min. 250 °C - Color Amber to Yellow - - Density (at 20°C) 1.1 g/cc - Dispersible in (at 20°C) Water - - Flash Point min. 115 °C - Ignition Temperature min. 350 °C - pH Value (1% suspension in water at 20 °C) 7.2 - - Physical Form Liquid - - Vapor Pressure (at 20°C) 1.00X10⁻⁴ Pa - - Solubility Data

Value Units Test Method / Conditions 1-Methoxy-2-propylacetate Solubility (at 25°C) min. 50 g/100g solvent - Xylene Solubility (at 25°C) min. 50 g/100g - Butyl Acetate Solubility (at 25°C) min. 50 g/100g - Butylcarbitol Solubility (at 25°C) min. 50 g/100g - Methyl Ethyl Ketone Solubility (at 25°C) min. 50 g/100g - Water Solubility (at 25°C) max. 20 g/100g -

Regulatory & Compliance

Technical Details & Test Data

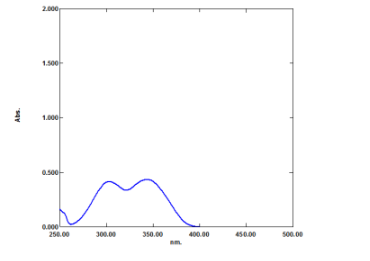

- UV Visible Spectrum Graph

UV-Vis. Spectrum λmax.=343nm & 302nm (20ppm in THF)

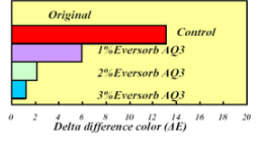

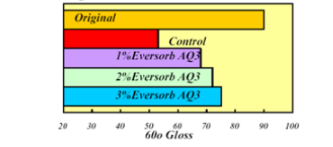

- Experiments

- Resin: Polyurethane (PU) Waterborne Clear Coating

- Application: SprayPreparations: Air dry for 6 hours

- Film Thickness: 85 microns (wet); 35 microns (dry)

- Exposure Unit: Q-U-V with UVB-313 light bulb

- Test Methods: ASTM G154

- Gloss Retention and Yellowness Index: ASTM G 154

- Exposure Time: 1000 hours

- Dosage: 1~3% Solid content

Fig.2-1-1 Delta color difference (4E)

Fig.2-1-2 60o Gloss

Packaging & Availability

Storage & Handling

- Storage Conditions

Eversorb® AQ3 should be kept in a dry, dark place without any light exposure.