Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Manufactured By

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Product Advantages

- Excellent compatibility with epoxy A/B offering homogeneous distribution during processing.

- High resistance to UV degradation.

- It is suitable for the amine cured EPOXY and does not affect initial color of the system.

Applications & Uses

- Compatible Polymers & Resins

- Use Level

- 0.5 - 3.0 wt% based on epoxy (A+B)

- Recommeded Applications

Eversorb® EP4 can be used in amine-based epoxy systems. In general, it is recommended to be used at 0.5 to 3.0wt% based on epoxy (A+B).

Properties

- Physical Form

- Appearance

- Clear, slight yellow liquid

- Typical Properties

Value Units Test Method / Conditions Melting Point 26 - 28 °C - Viscosity approx. 9000 cPs - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Solubility in Water (at 20°C) max. 0.1 % - Density (at 20°C) 1.13 g/cc - Vapor Pressure (at 20°C) 1.0E-⁴ Pa - Ignition Temperature min. 400 °C - Flash Point min. 100 °C - Boiling Point min. 400 °C - Melting Point 27 -28 °C - Odor None - - Color Slight Yellow - - Physical Form Liquid - -

Regulatory & Compliance

Technical Details & Test Data

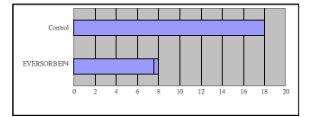

- UV-resistant Test

- USE Epoxy

- A-PART:CHANG CHUN GROUP 188

- B-PART:YUN TEH INDUSTRIAL 905-3SH-1 (Modified Cyclo-aliphatic amine)

- A:B=2:1(wt%) 50°C thermal curing 24hrs

- Sample: 3mm thick plastic block / epoxy

- Exposure: QUV 340nm (70°C*1.35W/m2)

- Test Time: 48hrs

- Additive: 0.5 wt% base on epoxy A+B (incorporated in hardener B)

- Measurement: Delta yellowness index (∆YI)

Packaging & Availability

Storage & Handling

- Storage Conditions

- Eversorb® EP4 should be stored in a close system and be kept in a dry, dark place without any light exposure.

- It’s advised to store this material above 28°C to maintain liquid form for the ease of handling.

- In the case of solid formation, Eversorb® EP4 can be re-melted by heating at 50°C waterbath.