Enhanced TDS

Identification & Functionality

- Chemical Family

- Manufactured By

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Product Applications

- Plastistrength® 562 process aid is particularly recommended for vinyl siding, window sills, wall panels, pipes and any other kind of rigid PVC application.

- Customers should evaluate Plastistrength® 562 process aid in their own laboratories to optimum conditions for use in their processes and applications.

- Plastistrength® 562 process aid leverages Arkema expertise on optimization of additive powder properties for use in PVC processes.

- General Information

Filler Dispersion

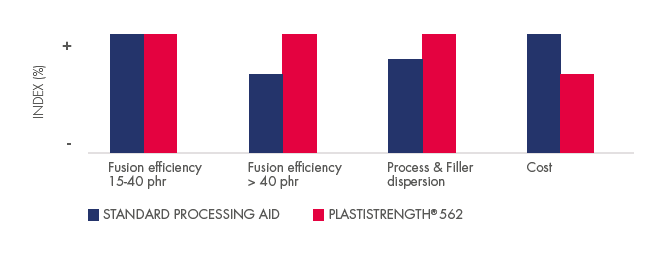

- Thanks to its high molecular weight and innovative composition, Plastistrength® 562 process aid delivers optimum melt strength and fusion behaviour to rigid PVC formulations.

- This allows for better dispersed particles within the PVC matrix, which improves mechanical properties as well as the surface finish quality.

Properties

- Physical Form

- Appearance

- White powder

- Typical Physical Properties

Value Units Test Method / Conditions Bulk Density 0.5 g/cc - Particle Size 2 % - Percent Volatile 1 wt% - Specific Gravity 1.11 - - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Auto Ignition Tempertaure approx. 824 - 878 °F - Color White - - Form Powder - - Odor Very faint, ester - like - - Particle Size (retained on 40 mesh) min. 10 μm - Physical State Solid - - Thermal Decomposition Temperature approx. 572 °F -

Regulatory & Compliance

Technical Details & Test Data

- Formulation Cost

- Because of its high molecular weight and unique composition, Plastistrength® 562 process aid offers an optimized compromise between performance and formulation cost.

- Compared to standard process aids, Plastistrength® 562 process aid allows significant dosage reduction.

- Product Benefits