Enhanced TDS

Identification & Functionality

- Chemical Family

- Manufactured By

- Plastics & Elastomers Functions

- Technologies

- Product Families

Applications & Uses

- Plastics & Elastomers End Uses

- Suggested Use Levels

- Plastistrength® 562 NA process aid is particularly recommended for highly filled substrate applications like luxury vinyl tile or vinyl siding substrate, PVC conduit, and semi-rigid or rigid PVC applications where enhanced fusion promotion is desired.

- Customers should evaluate Plastistrength® 562 NA process aid in their own laboratories to optimize conditions for use in their processes and applications.

Properties

- Physical Form

- Appearance

- White powder

- Typical Properties

Value Units Test Method / Conditions Percent Volatile max. 1 wt% - Particle Size (retained on 40 mesh) 2 % - Bulk Density 0.55 – 0.75 kg/m³ - Specific Gravity 1.11 - - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Auto Ignition Temperature 824 - 878 °F - Appearance White Solid Powder - - - Powder Properties

- Plastistrength® 562 NA process aid leverages Arkema expertise on optimization of additive powder properties for use in PVC processes.

Technical Details & Test Data

- Techical Information

- FILLER DISPERSION

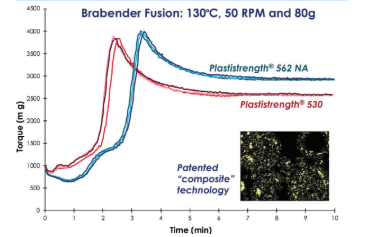

Thanks to its high molecular weight and innovative composition, Plastistrength® 562 NA process aid delivers optimum melt strength and fusion behavior to rigid and semi-rigid PVC formulations. This allows for better dispersion of inorganic fillers and additives within the PVC matrix, which improves melt processing and mechanical properties.

Component

phr PVC resin (0.82 IV) 100 Ca / Zn stabilizer 2.5 Stearic acid 0.2 Vikoflex® 7170 (ESO) 10 Plasticizer (DOTP) 20 Plastistrength® Process Aid 3 Calcium carbonate (3um) 250

Titanium dioxide2.5 - FORMULATION COST

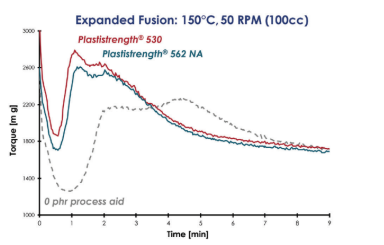

Because of its high molecular weight and unique composition, Plastistrength® 562 NA process aid offers an optimized balance between performance and formulation cost. Compared to standard process aids, Plastistrength® 562 NA process aid allows cost reduction without compromising melt processing performance.

Component

phr PVC resin (0.91 IV)

100 Ca / Zn stabilizer 2

Vikoflexª 7170 (ESO]2 Plasticizer (DOTP) 20 Plastistrength® Process Aid 0 or 1.5