Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Manufactured By

- Pigment Type

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers Processing Methods

- Suggested Use Levels

Ti-Pure™ R-350 is optimized for polyolefin and ABS applications. R-350 allows a plastics formulator to design products that can be used in diverse applications ranging from general purpose plastics, durable/non-durable plastics and high quality products with critical end use applications. R-350 demonstrates excellent dispersion, marvelous processibility, exceptionally low volatility and enhanced durability. This combination of functions in one TiO₂ make R-350 the prime choice for high temperature cast films, exterior films and general purpose applications while providing excellent assurance against discoloration.

Chemours Titanium Technologies pioneered the development of products that provide high opacity and blue undertone. This optical performance is something that is expected from Ti-Pure™ TiO₂ products. R-350 continues Chemours Titanium Technologies’ commitment to produce a TiO₂ that can provide bright blue and clean appearance to plastics.

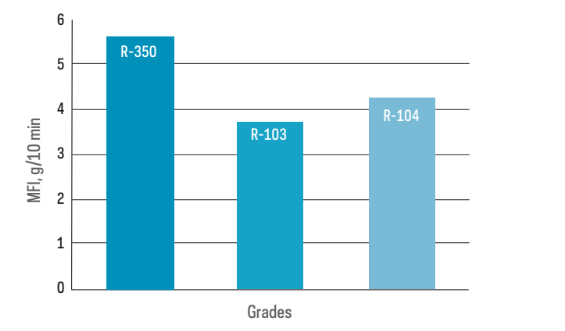

The Ti-Pure™ R-350 surface allows for exceptional processing even in highly loaded TiO2 PE systems. Unique R-350 chemistry permits the product to achieve desirable masterbatch viscosities in a wide variety of polyolefin based resins. This function allows a formulator to minimize the TiO₂ impact on melt properties during processing and end use applications (Figure 1).

Figure 1. Melt Flow Index (MFI)

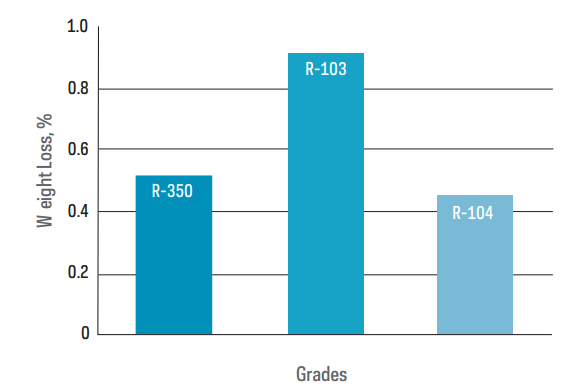

The unique surface of Ti-Pure™ R-350 minimizes volatile materials typically associated with TiO₂. Thermogravimetric Analysis (see Figure 2) highlights the low level of volatiles contained in R-350. This characteristic gives R-350 superior performance in high temperature, thin gauge extrusion applications such as polyolefin cast film or extrusion coating.

Figure 2. High Temperature Weight Loss

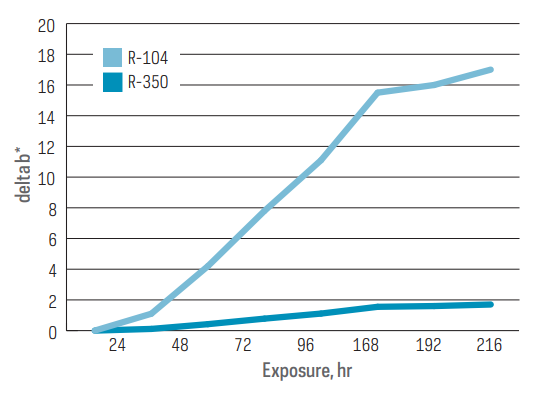

Another benefit from using Ti-Pure™ R-350 is the ability to use the TiO2 in combination with materials that tend to discolor. Certain polymer additives can interact with a TiO₂ surface. Under UV light illumination, this interaction can lead to discoloration. The R-350 chemistry minimizes the risk of discoloration. (see Figure 3).

Figure 3. Polyethylene Discoloration

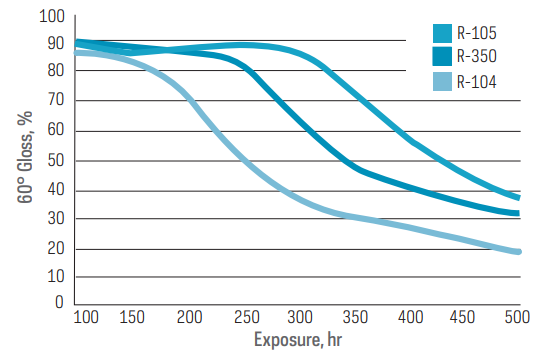

Ti-Pure™ R-350 has the ability to absorb ultraviolet light with minimal impact on the polymer matrix. A means of determining the impact is to monitor the change in surface gloss of a plastic article during ultraviolet exposure. Typically, the surface gloss of an article willdecrease as exposure time increases (see Figure 4). R-350 performs admirably in comparison to general purpose TiO₂ and provides the durability necessary for many polyolefin applications.

Figure 4. Polyolefin Gloss Retention

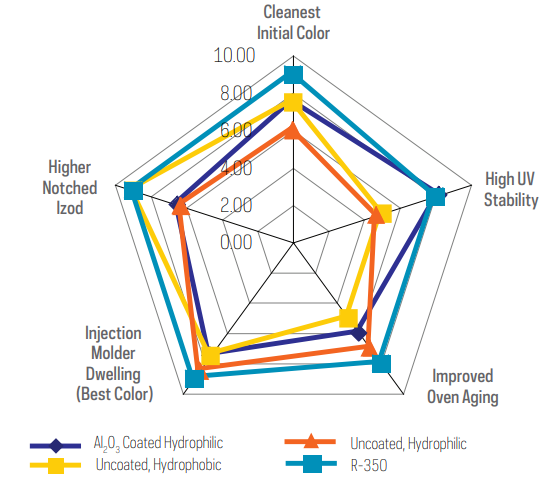

In ABS resin applications, R-350 provides a bright clean initial color. R-350’s unique surface treatment gives excellent thermal and UV stability, helping to maintain that brand new look. The superior dispersion of R-350 allows ABS to better retain mechanical impact properties in demanding applications. R-350 provides the optimal blend of performance in ABS

Figure 5. ABS Performance — Summary Data

R-350 provides the best-balanced performance in ABS attributes.

Properties

- Color (Properties)

- Physical Properties

Value Units Test Method / Conditions Loss on Ignition (at 1000°C for 2hr) 99 - - Specific Gravity 4.1 - - Titanium Dioxide Content min. 95 wt% - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Oxidising Properties The substance or mixture is not classified as oxidizing. - - Explosive Properties Not Explosive - - Decomposition Temperature The substance or mixture is not classified self-reactive - - Relative Density 3.6 - 4.3 - - Flammability (Solid, Gas) Not expected to form explosive dust-air mixtures. - - Flammability (Solid, Gas) Will not burn - - Insoluble in Water - - Initial Boiling Point 3000 °C - Melting Point 1843 °C - Odor Odorless - - Appearance White crystalline - -