Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Manufactured By

- Plastics & Elastomers Functions

- Technologies

- Product Families

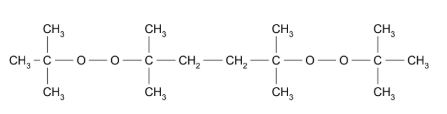

- Chemical Structure

Applications & Uses

- Compatible Polymers & Resins

- Application Information

Trigonox 101 is an efficient peroxide for the degradation of polypropylene (CR-PP) in the temperature range of 200-250°C.

Controlled rheology polypropylene

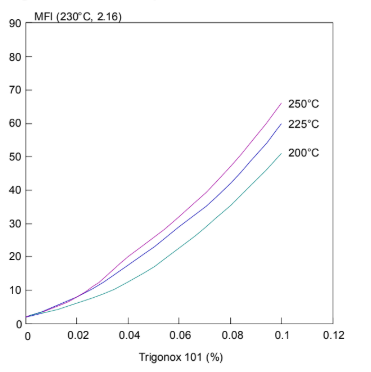

Trigonox 101 allows polypropylene producers great flexibility in controlling a polymer’s Melt Flow Index (MFI). Small changes in either peroxide concentration or process temperature can produce significantly different MFI’s. Examples of this can be seen in Figure 1 where the relationship between MFI and peroxide concentration is shown at three temperatures.The experiments represented in this figure were conducted using a Brabender Plasti-Corder ® PLE-330 and a Brabender Extrusiograph® 25D/ 19 mm, with a 4:1 3-zone screw (mixing part 10D, 3D, 9D/3D). Melt flow indices were determined using a Davenport melt flow indexer, model number 3, according to ASTM D 1238, condition L (230°C/2.16 kg). The polypropylene used was stabilized with 0.1% butylated hydroxytoluene (BHT).

Figure 1. Effect of peroxide concentration on MFI

Polymerization of styrene

Trigonox 101 can also be used as chaser catalyst to reduce residual monomer in the mass polymerization of styrene.

Properties

- Physical Form

- Appearance

- Clear liquid

- SDS Physical and Chemical Properties

Value Units Test Method / Conditions Active Oxygen Content min. 10.14 % - Organic Peroxides min. 92 % - Oxidising Properties The substance or mixture is not classified as oxidizing. - - Explosive Properties Not Explosive - - Kinematic Viscosity (at 20°C) 8.54 mm²/s - Dynamic Viscosity (at 20°C) 7.35 mPa.s - Self-Accelerating Decomposition Temperature 80 °C SADT Decomposition Temperature SADT - Self accelerating decomposition temperature - - Partition Coefficient (at 20°C, N-octanol/water, log Pow) 7.34 - - Immiscible in Water - - Relative Density (at 20°C) 0.872 - - Vapor Pressure (at 20°C) max. 0.01 hPa - Flammability (Liquids) Combustible liquid - - Flash Point (at 1013 hPa) 68 °C - Boiling Point Decomposes below the boiling point - - Melting Point 1 - 10 °C - Odor Characteristic - - Soluble in Organic solvent - - Appearance light yellow, clear liquid - - - Specifications

Value Units Test Method / Conditions Active Oxygen Peroxide Content 11.02 % - Melting Range 1 - 10 °C - Viscosity 6.4 mPa.s - Active Oxygen Content min. 10.14 % - Density 0.87 g/cc - Hydroperoxides as (2,5-dihydroperoxy-2,5-dimethylhexane) max. 0.3 % - Assay Content min. 92.0 % - Color max. 50 - Pt-Co / APHA Molecular Weight 290.4 - - - Half-life Data

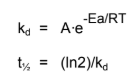

The reactivity of an organic peroxide is usually given by its half-life (t1/2) at various temperatures. For Trigonox 101 in chlorobenzene:

- 0.1 hr at 156°C (313°F)

- 1 hr at 134°C (273°F)

- 10 hr at 115°C (239°F)

The half-life at other temperatures can be calculated by using the following equations and constants:

- Ea = 155.49 kJ/mole

- A = 1.68E+16 s-1

- R = 8.3142 J/mole·K

- T = (273.15+°C) K

- Thermal stability

Organic peroxides are thermally unstable substances, which may undergo self-accelerating decomposition. The lowest temperature at which self- accelerating decomposition of a substance in the original packaging may occur is the Self-Accelerating Decomposition Temperature (SADT). The SADT is determined on the basis of the Heat Accumulation Storage Test.

For Trigonox 101 - SADT : 80°C (176°F)

The Heat Accumulation Storage Test is a recognized test method for the determination of the SADT of organic peroxides (see Recommendations on the Transport of Dangerous Goods, Manual of Tests and Criteria - United Nations, New York and Geneva).- Major Decomposition Products

Acetone, Methane, tert-Amyl alcohol, tert-Butanol, Ethane

Regulatory & Compliance

Safety & Health

- Safety Information

- Keep containers tightly closed. Store and handle Trigonox 101 in a dry well-ventilated place away from sources of heat or ignition and direct sunlight. Never weigh out in the storage room.

- Avoid contact with reducing agents (e.g. amines), acids, alkalis and heavy metal compounds (e.g. accelerators, driers and metal soaps).

Packaging & Availability

- Country Availability

- Packaging Information

- In North America Trigonox 101 is packed in non-returnable, 5 gallon polyethylene containers of 35 lb net weight and 15 gallon drums of 100 lb net weight.

- In other regions the standard packaging is a 30-liter HDPE can (Nourytainer®) for 25 kg peroxide solution.

- Both packaging and transport meet the international regulations. For the availability of other packed quantities contact your Akzo Nobel representative.

- Trigonox 101 is classified as Organic peroxide type D; liquid, Division 5.2; UN 3105.

Storage & Handling

- Shelf Life

- 3 months

- Storage Information

Due to the relatively unstable nature of organic peroxides a loss of quality can be detected over a period of time. To minimize the loss of quality, Akzo Nobel recommends a maximum storage temperature (Ts max.) for each organic peroxide product.

For Trigonox 101

- Ts max. = 40°C (104°F) and

- Ts min. = 10°C ( 50°F)

When stored under these recommended storage conditions, Trigonox 101 will remain within the Akzo Nobel specifications for a period of at least three months after delivery.