Enhanced TDS

Identification & Functionality

- INCI Name

- Manufactured By

- Cosmetic Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Benefit Claims

- Labeling Claims

- Key Features

- Readily water soluble Shorter mixing time in production

- Alcohol tolerance up to 40% Broad range of use for several regions

-

Superior performance to PVP/VA Excellent formulating latitude, broad range of use, easy to incorporate into existing product formulations

-

Natural derivation Improved sustainability and renewability versus synthetic polymers, friendly INCI name for product labels, acceptable for use in certified natural formulations

-

Compatible with commonly used formulation ingredients Robust and reliable performance

-

Requires no neutralization Streamlines formulating

Applications & Uses

- Markets

- Applications

- Application Format

- Hair Care Applications

- Use Level

- Waxes and Pomades 1 - 6%, Creams and Lotions 1 - 6%, Mousse 1 - 6%, Non-Aerosol Hairspray 1 - 6%

- Application Information

- Amazeᵀᴹ SP polymer is a unique, hair styling product derived from plant based sources. Amaze™ SP is a naturally derived homopolymer of itaconate. The polymer is polymerized in the presence of base under green conditions with water as the only solvent. The green processing uses very low energy and produces zero waste or by-products. As the itaconate source is non-GMO, this styling polymer is suitable for use in natural certified formulations. It is supplied as a 100% active powder which can easily be incorporated into any aqueous based formulations while also offering compatibility with ethanol. The polymer is anionic and quite polar, so some special considerations should be taken when formulating with the product. Being 100% naturally derived, Amaze™ SP delivers performance similar to PVP/VA or BIOSTYLE™ polymers with some additional benefits.

- Use in Emulsion

- Due to the nature of the material,Amaze™ SP polymer can cause some compatibility issues when formulated into emulsions. However,Amaze™ SP polymer shows an increased stability in these systems when the pH is brought to a more neutral range.

- Thermal Protection

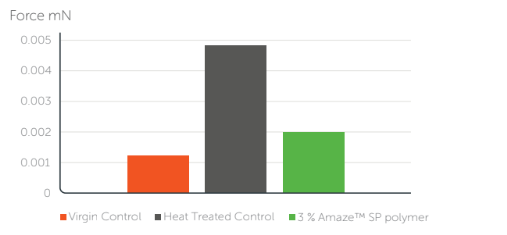

- Thermal Protection ofAmaze™ SP polymer vs. heated blank

- ThatAmaze™ SP polymer offers a substantial amount of protection from heated styling tools up to temperatures of 450°F (232°C). When compared to a heat-treated control withno thermal protection, Amazeᵀᴹ SP provides an improvement of nearly 80%

Properties

- Physical Form

- Soluble in

- Water and Ethanol

- SDS Physical and Chemical Properties

Value Units Test Method / Conditions Minimum Ignition Energy min. 9,999 mJ - Dust Explosion Class St2 - - Explosive Properties Not Explosive - - Flammability (Solid, Gas) May form combustible dust concentrations in air during processing, handling or other means. Not classified as a flammability hazard - - pH Value (10% in water) 4.8 - 5.6 - - Odor Odorless - - Color Off-White - - Appearance Powder - - Soluble in Water - - - Performance Properties

- Subjective evaluations were performed by a group of trainedpanelists on hair tresses to determine the performance of Amaze™ SP polymer compared to PVP/VA in pump hair sprayformulations. As can be seen in the study below, tresses weretreated with 3% and 6% Amazeᵀᴹ SP polymer and compared to3% PVP/VA. The tresses were then dried before panelists evaluatedthe swatches in a forced comparison to determine any differencein the performance attributes. The data below is a result of thiscomparison and is reported at a 95% confidence level.

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Neautralization

- Amaze™ SP polymer does not require neutralization. However, other polymers in the final formulation may require neutralization and should be done as recommended by the manufacturer.

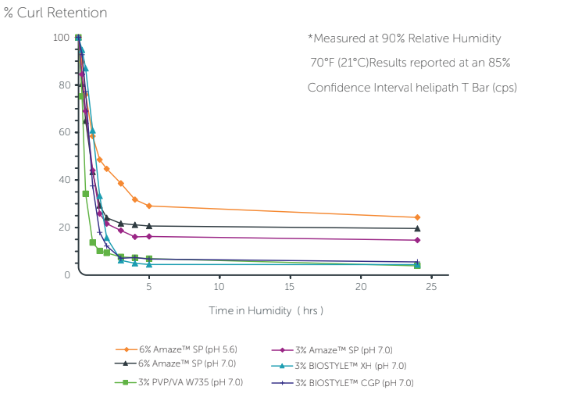

- High Humidity Curl Retention of Amazeᵀᴹ SP polymer vs. PVP/VA and BIOSTYLETM polymers

- Amaze™ SP polymer offers a statistically superior difference in humidity resistance when compared to PVP/VA Copolymer and BIOSTYLE™ polymers, as measured by curl retention after 24 hours. Additionally, there was no significant difference observed when varying the amount ofAmaze™ SP polymer from 3% to 6% in application, nor was there a difference in applying the product as is or with a more neutral pH.

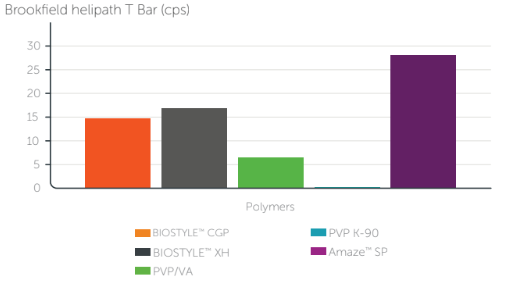

- Volume Enhancement

- The degree of volume enhancement offered by Amaze™ SP polymer compared to PVP/VA and BIOSTYLE™ polymers can truly be seen. While the BIOSTYLE™ polymers are known to build volume,Amaze™ SP polymer presents even more volume generation when applied to fine hair; these samples were evaluated at 3% polymer loadings at 50% Relative Humidity | 72° F (22°C).

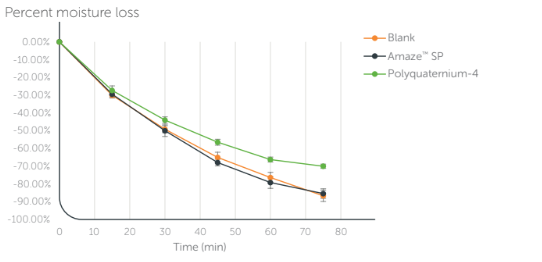

- Accelerated drying time

- Amaze™ SP polymer has been observed to dry significantly faster than other hair styling film formers. These observations are evident both objectively as well as subjectively. While the faster dryingAmaze™ SP polymer can be felt with heated styling tools, the difference in drying times is most obvious in air dried applications. The reason for this is because of the polymer behavior on hair. As opposed to a traditional film forming polymer which creates an even continuous film,Amaze™ SP is observed to interact at specific sites along the hair shaft. This behavior allows for the hair to remain partially exposed to the environment, and thus release\ excess moisture on the hair into the air.

- Basic Aerosol Mousse Formulation – 3% Polymer

*Measured at 30% Relative Humidity | 70°F

Packaging & Availability

Storage & Handling

- Shelf Life

- 24 months

- Storage Information

- Amaze™ SP polymer should be stored under ambient conditions; under these conditions, the product has a 24-month shelf life. The product is supplied in either a cardboard box or a fiber drum and should be kept tightly sealed and in a cool location to prevent unintended microbial contamination or yellowing.