Enhanced TDS

Identification & Functionality

- INCI Name

- Manufactured By

- Cosmetic Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Benefit Claims

- Labeling Claims

- Key Features

- Substantive to hair and skin without build up

- Imparts smooth feel to hair and skin

- Forms clear, glossy and tough films

- Improves wet combability

- Provides excellent high humidity curl retention

- Forms clear aqueous solutions

Applications & Uses

- Markets

- Applications

- Application Format

- Hair Care Applications

- Skin Care Applications

- Use Level

- 0.1 - 0.5% (cleansing applications), 0.5 - 3.0% (styling applications)

- Product Applications

Celquat® L-200 polymer is an excellent conditioning film former. Suggested applications include styling and conditioning mousses, creams, lotions, gels, conditioners, as well as skin creams and lotions.

- Formulation Guidelines

Solubility

Celquat® L-200 polymer is water soluble. It is recommended that the Celquat® L-200 polymer phase contain no more than 8% polymer by weight. For optimal results, prepare the Celquat® polymer solution as a separate phase. Slowly sift the powder into water while stirring. Sifting slowly will avoid the formation of fisheyes and gels. Heat and moderate agitation will increase the solubility rate of the polymer. The polymer is completely hydrated when the solution is clear and there are no insolubles present. Complete hydration is important to ensure homogeneity, viscosity stability, formulation stability, and clarity.

pH stability

Solutions of Celquat® L-200 polymer are subject to chemical hydrolysis at extreme pH. A pH range of 4 to 8 is recommended for optimal stability.

Thickening

Certain formulations based on Celquat® L-200 polymer may require additional thickening to improve their application or use. Commonly used cellulosic type thickeners are effective in raising the solution viscosity, including hydroxyethyl cellulose and hydroxypropyl methylcellulose. Blending with the higher viscosity Celquat-SC-230M polymer (Polyquaternium-10) can build viscosity. Finally, an effective associative thickener can raise the viscosity of solutions containing Celquat L-200 conditioning polymer.

Preservation

Aqueous solutions of Celquat polymers are subject to bacteriological growth and enzyme catalyzed degradation. Preservatives suggested for consideration are DMDM hydantoin, methyl p-hydroxybenzoate, propyl p-hydroxybenzoate, Germall® 115 and 2 nitro-2 bromo-1, 3 propanediol. The presence of alcohol will also minimize bacteriological growth.

Properties

- Physical Form

- Soluble In

- Typical Properties

Value Units Test Method / Conditions pH Value 4 - 8 - - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Minimum Ignition Energy 100 - 300 mJ - Dust Deflagration Index 52 m.b/s - Dust Explosion Class St1 - - Bulk Density 500 kg/m³ - Density 480 kg/m³ - Lower Explosion Limit 30000 mg/m³ - Flammability (Solid, Gas) Not classified as a flammability hazard - - Ignition Temperature min. 100 °C - pH Value (at 2 % solution) 6 - 8 - - Soluble in Water - - - Compatibility

Surfactant

Due to its higher cationic activity, Celquat® L-200 polymer is generally less compatible with surfactants than its analog Celquat® L-100 polymer. Celquat® L-200 is not recommended for use in clear systems with high amounts of anionic surfactant.

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Product Information

Celquat® L-200 polymer is one member of the Celquat family of polymers that are water soluble quaternary cellulose derivatives. Other Celquat polymers offered include:

- Celquat® H-100 polymer, Polyquaternium-4

- Celquat® SC-230M polymer, Polyquaternium-10

- Celquat® SC-240C polymer, Polyquaternium-10

Polyquaternium-4 conditioning polymers are formed by grafting dimethyl diallyl ammonium chloride groupsonto a cellulosic backbone. The Polyquaternium-4 polymers differ from the Polyquaternium-10 polymers in their comb-like distribution of the quaternized nitrogen charge rather than an even charge distribution. Celquat® L-200 polymer is a low viscosity Polyquaternium-4 variant.

It differs from the higher Celquat® H-100 polymer in not only molecular weight, but also in degree of cationic substitution. Celquat® L-200 polymer has approximately 2% nitrogen, which is double that of the Celquat® H-100 polymer.

Because of its lower molecular weight and higher cationic substitution, Celquat® L-200 polymer is recommended for use in low viscosity systems that require conditioning benefits, such as mousses. Celquat® L-200 polymer can be used in both styling and cleansing application areas, although the Celquat® L-200 polymer is the least tolerant of anionic ingredients of all the Celquat polymers.- Performance Properties

Styling applications

Celquat® L-200 polymer can have many applications in the hair care area, although the bulk of its use is in styling mousses. This polymer can be used in conditioning mousses, conditioning creams or lotions, and other styling aids.

Humidity Resistance

Celquat® L-200 polymer is an excellent film former. The polymer has good holding power in high humidity curl retention tests. In one test procedure, hair swatches were treated with various fixatives and were combed out, formed into curls, dried, and conditioned at 50% relative humidity. They were then mounted, unwound into a helix configuration, measured and placed in a chamber maintained at 21°C and 90% relative humidity. Curl height was determined as a function of time.

Percent curl retention is calculated by the following equation:

% curl retention = L - Lt / L - L0Where:

L = length of hair fully extended

L0 = length of hair before exposure

Lt = length of hair after exposure for time

Nine determinations were made with each sample. The results of the evaluation are given below:

PDMDAMC: Polydimethyldiallyl Ammonium Chloride HEC: Commercial Cationic Hydroxyethyl Cellulose Cationic VP: Cationic Vinyl Pyrrolidone Copolymer 70VP / 30VAC: 70 Vinyl Pyrrolidone/ 30 Vinyl Acetate Copolymer PVP: Polyvinylpyrrolidone

This data shows that the Celquat® L-200 polymer has superior high humidity curl retention when compared to cationic vinyl pyrrolidone copolymer, 70% vinyl pyrrolidone/30% vinyl acetate copolymer, polyvinylpyrrolidone, and poly dimethyl diallyl ammonium chloride.

The polymer also has slightly higher high humidity curl retention when compared to the Celquat® H-100 polymer and commercial hydroxyethyl cellulose after a two-hour time period.

Cleansing systems

The physical and sensory properties of the Celquat® L-200 polymer make it well suited for use in cleansing applications. However, the Celquat® L-200 polymer has some formula limitations due to the nature of its cationic charge. Some incompatibilities will occur when using the polymer with anionic surfactants.

Substantivity

The cationic charge on the Celquat® L-200 polymer makes it substantive to such keratinous substrates as hair and skin. The substantivity of Celquat® L-200 polymer has been defined using the Lumicrease Dye Test. In this experiment, dyeing wool swatches with an anionic polyazo sulfonate dye after they have been treated with the cationic polymer quantifies deposition of cationic conditioning polymers.

Wool is similar to human hair and skin in adsorptive and charge properties and can be used as an efficient substitute substrate for hair testing. The dye is attracted to the deposited cationic polymer. A colorimeter is used to measure the degree of adsorption on each sample via intensity of the dye.

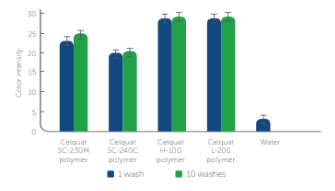

The swatches are tested for deposition after 1 wash (1) and 10 washes (10). The 1 wash data is indicative of substantivity, and a significantly higher value for the 10 wash reading over the 1 wash reading is indicative of build-up.

As is shown in the following graph, the Celquat® L-200 polymer is significantly more substantive than the two Polyquaternium-10 polymers, and is equally substantive as the Celquat® H-100 polymer. This data also shows that this polymer does not build-up on the wool swatches during repeated washings.

Substantivity of Celquat® conditioning polymers

Safety & Health

- Health and Safety

A health and safety summary for Celquat® L-200 polymer is available upon request. Information on Celquat® L-200 polymer relating to EU Cosmetic Directive 76/768/EEC is also available upon request.

This product may be used in spray applications having a droplet particle size greater than 50 microns. The product has not been properly evaluated for safety clearance for use in pumps and/or aerosols with particle sizes less than 50 microns.

The suitability of the final formulations should be confirmed in all respect by appropriate evaluation. The marketer is advised to evaluate the final formulation with regard to performance and health safety.

Packaging & Availability

Storage & Handling

- Storage Information

Celquat® L-200 polymer should be stored in a cool, dry location away from heat, sparks and fire. When not in use, the container should be kept closed to prevent moisture and dust contamination. We recommend that normal precautions be taken to avoid ingestion or contact with eyes. Respiratory protection should be used to avoid dust inhalation. Good industrial hygiene practices should be followed.