Enhanced TDS

Identification & Functionality

- INCI Name

- Manufactured By

- Cosmetic Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Benefit Claims

- Labeling Claims

- Benefits and Features

Broad compatibility

- Compatibility with other ingredients offers formulation flexibility.

- Can be used with a wide range of other raw materials such as oils, emollients, silicones, UV filters, vitamins, botanical extracts, alpha and beta hydroxy acids, dihydroxyacetone, fragrances and dyes.

Tapioca starch

- Aluminum-free modified natural polymer.

- Biodegradable, based on non-genetically modified starch.

- Low protein content for sensitive skin and reduced allergy concerns.

- Free-flowing. Soft, powdery feel.

- Non-whitening on the skin.

- Talc replacement.

- Easily dispersed in cold water.

- Cost effective additive for a variety of skin care products.

- Improves aesthetics of a broad spectrum of formulations.

Oil-adsorber

Mitigates greasiness of lotions, creams, and ointments

Applications & Uses

- Markets

- Applications

- Application Format

- Hair Care Applications

- Skin Care Applications

- Use Level

- max. 30% (Ointments), 5 - 95% (Powders), max.10% (Traditional Creams and Lotions), 1% sprays(Emulsions)

- Formulation Guidelines

- Processing requirements

- For use in the powder form, Dry-Flo TS/TS Pure starches can be handled like any other natural starches.

- For use in emulsion and hydroalcoholic systems, the starches should be added as a powder directly to the emulsion with proper mixing.

- Care must be taken to incorporate the starch at 45°C or below when used in aqueous systems.

- If temperatures above 45°C are encountered, the starch granule may begin to swell, reducing its effectiveness as an aesthetic enhancer and could potentially increase the formulation viscosity.

- Dry-Flo TS/TS Pure starches may also be slurried in glycols or glycerin and incorporated into the formula with proper mixing at temperatures below 45°C.

- While the biopolymer is tolerant to shear, it should not be extensively homogenized due to potential degradation of the starch.

- Compatibility

- Dry-Flo TS/TS Pure starches are compatible with a wide range of commonly used cosmetic raw materials, including anionic, non-ionic, and cationic ingredients.

- In addition, these polymers can be used with skin care actives such as sunscreens (organic and inorganic).

- Dry-Flo TS/TS Pure starches can also be used in combination with other thickeners and emulsifiers.

Properties

- Physical Form

- SDS Physical and Chemical Properties

Value Units Test Method / Conditions Oxidising Properties The substance or mixture is not classified as oxidizing - - Explosive Properties Not Explosive - - Slightly Soluble In Water - - Odor Characteristic - - pH Value (at 20% solution) 5 - 7.5 - - Appearance White powder - - - Specifications

Value Units Test Method / Conditions pH Value 4 - 8 - - - Product Properties

- First, since an aluminum salt is not used in the production of Dry-Flo TS/TS Pure starches, these products are aluminumfree.

- Second, Dry-Flo TS/TS Pure starches are modified with polymethylsilsesquioxane, which imparts a velvety and soft after-feel to the skin.

- Due to their desirable feel properties, Dry-Flo TS/TS Pure starches can be utilized to cost effectively improve aesthetics in a variety of cosmetic products.

- Useful as effective talc replacements, Dry-Flo TS/TS Pure starches are natural polymers which can adsorb oil and do not produce undesirable whitening on the skin.

- Perhaps the most distinctive property of these unique products is its ability to impart a pleasant light, dry, and silky after-feel to finished formulations.

- Dry-Flo TS/TS Pure starches have the ability to mitigate greasiness – even in formulations containing high levels of oil.

- Performance Properties

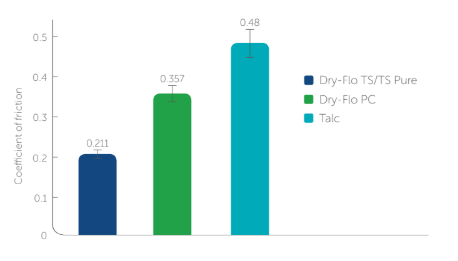

Friction

- Friction testing is a measurement of surface friction, i.e. the frictional force required to pull a material sample, at a specified speed, for a specified distance over a horizontal surface.

- In frictional force testing (COF testing), the sample is normally wrapped around a metal block of specific dimensions and mass - called a ‘sled’, and another sample of the material is attached to a horizontal table.

- The less friction the product displays, the more slippery and smoother it feels.

- The coefficient of friction (COF) results for Dry-Flo TS/TS Pure starches compared to other commercially available aesthetic enhancers are displayed in the figure below.

Coefficient of friction results for various aesthetic enhancers

Dry-Flo TS/TS Pure starches provides less friction (COF), which translates to a smoother feel on skin, compared to other aesthetic enhancers

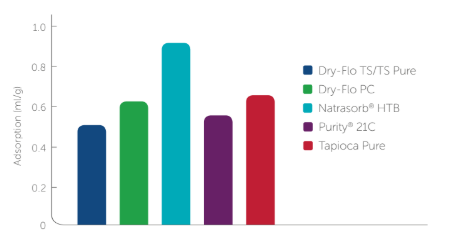

Oil-adsorption

- The oil adsorption of a powder is defined as the number of grams of synthetic sebum oil absorbed by 0.1-1.0 grams of the powder.

- Thus this test is a measure of the ability of a powder to hold onto oil.

- Dry-Flo TS/TS Pure starches were compared for oil adsorbency vs. other starches, with the results displayed in the figure below.

Oil adsorption of various starch technologies

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Safety & Health

- Health and Safety

- Dry-Flo TS/TS Pure starches are readily biodegradable and not genetically modified.

- In addition, Dry-Flo TS/TS Pure starches contain very low protein content which makes them suitable for sensitive skin or other products where allergens are of concern.

- The suitability of the final formulations should be confirmed in all respect by appropriate evaluation.

Packaging & Availability

Storage & Handling

- Storage Information

- Dry-Flo TS/TS Pure starches are a finely divided organic particulate.

- When handling, avoid generation of dust.

- Use in a well ventilated area.

- Use of a dust mask is recommended.

- Avoid contact of the Dry-Flo TS/TS Pure starches powder or dust with heat, sparks, or open flame.

- Dry-Flo TS/TS Pure starches should be stored in a cool, dry location away from heat, sparks, or fire. Good industrial hygiene practices should be followed when working with this starch.