Enhanced TDS

Identification & Functionality

- INCI Name

- Manufactured By

- Cosmetic Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Benefit Claims

- Labeling Claims

- Product Benefits

Features Benefits Low tack Smooth, non-raspy feel Low glass transition temperature Good flexible hold, curl retention and shape High film strength Excellent duration of hold Elasticity Provides control and manageability of several hair types

Exceptional performance in low VOC systems Broad range of formulation latitude Suitable for a wide range of product types Humidity resistant Long-lasting style, frizz control Thermal protection Enhanced styling performance

Applications & Uses

- Markets

- Applications

- Application Format

- Hair Care Applications

- Use Level

- 1% - 10%(Gel, mousse, pomade, creams and other styling products)

- Recommended Applications

DynamX® H₂O polymer is intended for use in styling products including gels, mousses, non-aerosol spritzes and thermal protection products, pomades, styling creams and ethnic styling products. It is not intended or recommended for use in aerosol hair sprays. It is designed to provide flexible, durable hold and high humidity curl retention across a broad range of styling product forms.

- Formulation Guidelines

Supplied as a liquid, DynamX® H₂O polymer is very simple to use. The product is a low viscosity liquid which goes readily into solution with no heating required. No neutralization is required as it is supplied fully neutralized. DynamX® H₂O polymer is easily removed from the hair with normalshampooing.

Compatibility

DynamX® H₂O polymer can be blended with other styling polymers in order to tailor formulations to your specific needs. For use in gels, it is compatible with the following rheology control polymers.

Rheology modifier Control

Structure® 2001 polymer Very slightly hazy; excellent hand clarity

Hydroxyethylcellulose Clear

Xanthan Gum Very slightly hazy; excellent hand clarity

DynamX® H₂O polymer is recommended for use in 6% VOC aerosol mousse formulations, as well as for non-aerosol mousse products. It is compatible with both Polyquaternium-4 and Polyquaternium-11, which are recommended for use in conjunction with DynamX® H₂O polymer in order to provide optimal wet styling properties.

DynamX® H₂O polymer is compatible with other styling product additives such as silicones, proteins, UV absorbers, panthenol.

Properties

- Physical Form

- Soluble In

- SDS Physical and Chemical Properties

Value Units Test Method / Conditions Odor Slight - - Appearance Colorless, light yellow liquid - - Oxidising Properties The substance or mixture is not classified as oxidizing. - - Explosive Properties Not Explosive - - Dynamic Viscosity max. 1,000 mPa.s - Soluble In Water - - Relative Density ca. 1 - - Vapor Pressure (at 20°C) max. 23 hPa - Boiling Point 100 °C Derived Melting Point 0 °C - pH Value 8.7 - 9.3 - -

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Performance Properties

The power behind DynamX® H₂O polymer is a unique, patented composition based on polyurethane and acrylate technology. The unique polymer structure of DynamX® H₂O polymer is specially designed to enhance performance in products designed for dynamic styling properties. The urethane portion of the product helps to provide hold, elasticity and flexibility for soft, touchable hair feel (without tack), while the acrylic functionality provides strength, humidity resistance and easy shampoo removability. The combination of these two polymer chemistries gives the overall product properties of strength, flexibility, and durability, which lead to truly dynamic styles.

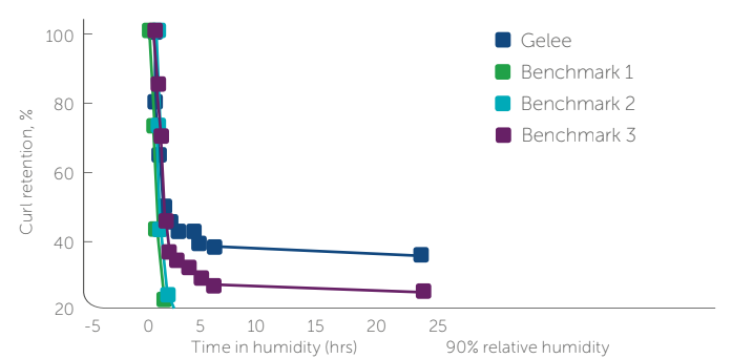

High humidity curl retention

DynamX® H₂O polymer can be used in the creation of products with excellent humidity resistance and lasting duration of hold. The polymer was incorporated into a clear hair gel at a level of 2% polymer solids and compared to commercially available styling gels for high humidity curl retention. As shown in the graph below, the product formulated with the DynamX® H₂O polymer had much greater humidity retention (at all time intervals measured) than any of the commercial benchmarks to which it was compared.

High humidity curl retention - DynamX® H₂O polymer “hair gelee” versus competitive benchmarks

DynamX® H₂O polymer can be effectively used in products to control frizz and define curls. When incorporated into a curl control and defining cream at a use level of 0.25%, the product was more effective than commercial benchmarks at controlling frizz. 16” curly Caucasian tresses were prepared with 0.75g of product applied to each. Tresses were left in a CTH room over night to dry, and then placed in a chamber at 90°F/90% RH for 24hrs. Photos were taken initially and 4 hours and 24 hours.

Initial

1. Blank ; 2. DynamX® H₂O ; 3. Benchmark 1 ; 4. Benchmarks 2 ; 5. Benchmark 3

4 hours

1. Blank ; 2. DynamX® H₂O ; 3. Benchmark 1 ; 4. Benchmarks 2 ; 5. Benchmark 3

24 hours

1. Blank ; 2. DynamX H2O ; 3. Benchmark 1 ; 4. Benchmarks 2 ; 5. Benchmark 3

Thermal protection

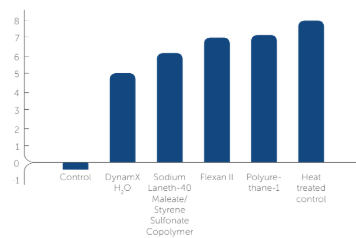

DynamX® H₂O polymer can also be incorporated into products designed to protect hair from the damaging effects of heating appliances, such as flat irons. In a test of thermal protection, DynamX® H₂O polymer was used in the formulation of a non- aerosol spritz and tested for its thermal protection properties via wetting force analysis. Wetting force analysis is an effective way to measure the effect of treatment temperature on the deposition and substantivity of polymers applied to the surface of hair. Wetting force is correlated with the contact angle of water on the surface of a hair fiber. This is implicitly correlated with the degree to which a single hair fiber is damaged. Hair fibers are more hydrophilic when damaged. The larger the wetting force, the more damaged the hair fiber.

The process involved 12 cycles of applying appropriate polymer spray, applying heat via flat iron at highest setting (410°F) – 5 min, washing and drying hair tress. A control sample was run without polymer applications. Each sample was evaluated for wetting force and image analysis by Scanning Electron Microscopy (SEM) Prior to the heating / application process each hair swatch sample was submerged in water for 5 min to completely hydrate the hair.

Average wetting force (mN)

In the data showed in the Average weeting force test, it can be seen that DynamX® H₂O polymer offers the best thermal protection performance as seen by the lowest wetting force of all products testing, indicating that the hair is less hydrophilic and therefore less damaged.

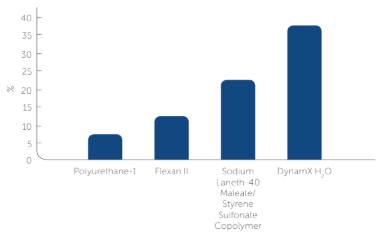

Improvement in wetting force (%)

The chart above shows a comparison of polymer technologies and their ability to protect hair from heat damage relative to a heat-treated control to which polymer protection was not applied. Results are expressed as % improvement in wetting force relative to the control sample. It can be seen that DynamX® H₂O polymer provides the highest wetting force improvement relative to heat control and DynamX® H₂O polymer delivers the best protection relative to other technologies.

Safety & Health

- Health and Safety

This product has not been properly evaluated for safety clearance for use in pumps/aerosols with particle sizes less than 50 microns.

A health and safety summary for DynamX® H₂O polymer is available upon request. Information on DynamX® H₂O polymer relating to EU Cosmetic Directive 76/768/EEC is also available upon request.

Packaging & Availability

Storage & Handling

- Storage and Handling Information

DynamX® H₂O polymer can be stored under ambient conditions without undergoing decomposition or degradation. When not in use, the container should be kept covered to prevent dirt, dust, and moisture pick-up. Store in a cool, dry area and protect from freezing.