Enhanced TDS

Identification & Functionality

- Chemical Family

- Manufactured By

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- Materials Features

Applications & Uses

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Use Level

- 10 - 60phr

- Properties and Applications

Edenol® 1208 is a polymeric plasticizer based on adipic acid and has a low viscosity. It consequently shows good properties when used in plastisol processing, for example dipping, rotational molding and casting applications, while still maintaining better extraction resistance compared with monomeric plasticizers.

Polymeric plasticizers are mainly used for PVC processing. They are, however, compatible with many other polymers including VC copolymers.

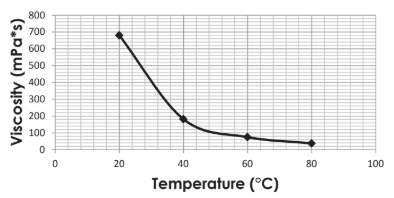

Viscosity

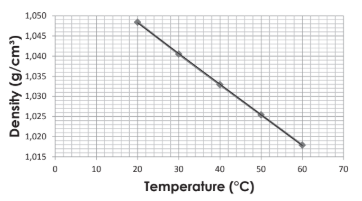

Density

Properties

- Physical Form

- Appearance

- Slightly yellowish, liquid

- Typical Properties

Value Units Test Method / Conditions Density (at 20°C) 1.03 - 1.07 g/cc DIN 51757 Refractive Index (at 20°C) 1.459 - 1.465 - DIN 51423, AOCS Tp 1a-64 Viscosity (at 20°C) 650 - 750 mPa.s DIN 53019, AOCS Ja10-87 Hydroxyl Value 0 - 30 mg KOH/g DIN 53240 Color 0 - 100 - DIN ISO 6271, ASTM D 1209, Hazen Acid Value 0 - 2.0 mg KOH/g DIN EN ISO 2114, AOCS Te 1-64 - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Viscosity (Room Temperature) 650 - 750 cPs Dynamic Density (at 20°C) 1.03 - 1.07 g/cc - Flash Point min. 260 °C ISO 2592, Open cup Color Yellowish - - Physical Form Liquid - -

Packaging & Availability

Storage & Handling

- Shelf Life

- 24 months

- Storage and Handling Information

It is recommended to store Edenol® 1208 at room temperature and to protect the product against the effects of heat and frost. If stored in sealed original packaging, Edenol® 1208 should be stable for at least 24 months from the date of manufacture.