Enhanced TDS

Identification & Functionality

- INCI Name

- Manufactured By

- Cosmetic Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Benefit Claims

- Labeling Claims

- Key Features

- Forms clear, flexible films

- Films contract upon drying

- Dissipates electric charge quickly

- Tolerates high temperatures, e.g. above 300°C

- Highly anionic

- Surface tension reduction

- Preservative free

- Benefits and Features

- Hair styling and fixative properties

- Locks in hair volume

- Skin tightening

- Curl revitalizing thermal protection

- Skin tightening smoothing fine wrinkles

- Anti-static properties preventing fly-away hair strands

- Thermal protection

- Effective removal of cationic build-up

- Enhances body and volume of hair by removing build-up

- Delivers healthy, shiny looking hair

- Easily formulated into cleansing systems

- Increased cleansing ability

- Global acceptance

Applications & Uses

- Markets

- Applications

- Application Format

- Hair Care Applications

- Recommended Applications

For hair care, it can be used to remove cationic build-up on hair, making it ideal for shampoos and cleansing products. Flexan II water soluble polymer film is strong and flexible, making it a multifunctional ingredient for various styling aids. Flexan II polymer film is heat stable well above 300°C and therefore protect the hair from heat damage caused by using hair dryers, curling irons, or flat irons during the styling process. Flexan II polymer is a highly anionic polymer with excellent electrical conductivity. It quickly dissipates electric charge and helps prevent flyaway strands. For skin care, its film forming properties tighten skin and smooth fine lines and wrinkles.

- Formulation Guidelines

Compatibility

In-vivo moisturizing efficacy is measured by the ingredient’s ability to increase the water content in the skin (stratum corneum). The measuring principle of the Corneometer is based on the dielectric constant in the medium and water has the greatest impact on the dielectric constant of the skin. Therefore, any increase in water content on skin can be determined by corneometer measurements.Solubility

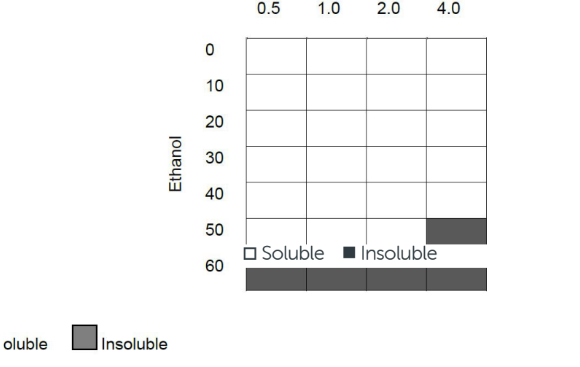

Flexan® II Polymer is readily soluble in water, glycerin and low molecular weight polyethylene glycols. It is insoluble in ethanol, but it will tolerate ethanol as a diluent in aqueous solutions. When making hydroalcoholic solutions, the Flexan® II Polymer should first be dissolved into the water portion and then the alcohol added with good agitation. The table to the below outlines the compatibility of the Flexan® II Polymer in aqueous-alcoholic solutions:

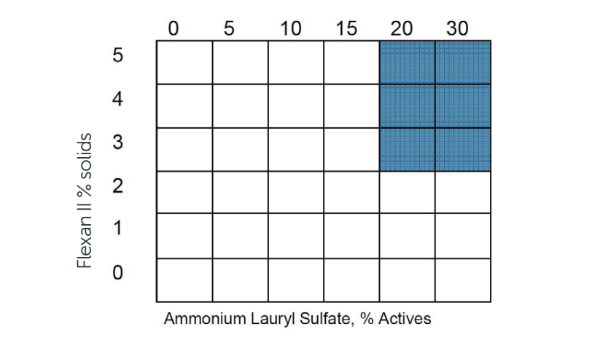

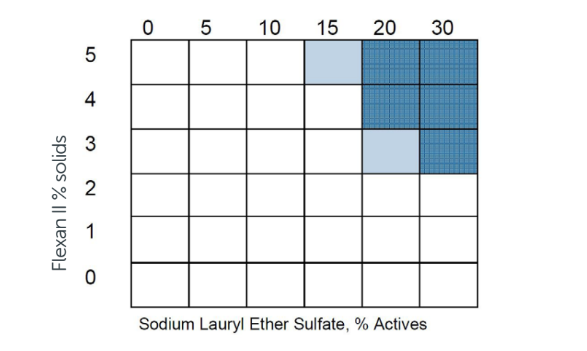

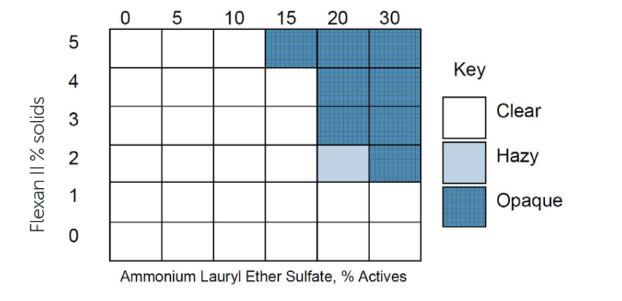

Surfactant compatibility

Flexan® II Polymer is highly compatible with surfactants such as those listed below, allowing it to be formulated into shampoos, body washes and other personal cleansing applications. When used at high levels, Flexan® II Polymer has limited compatibility at high concentrations of certain alkyl sulfates and certain alky ether sulfate surfactants. However, its wide range of compatibility still allows a good deal of latitude when formulating cleansing systems at typical use levels.Flexan® II Polymer surfactant compatibility

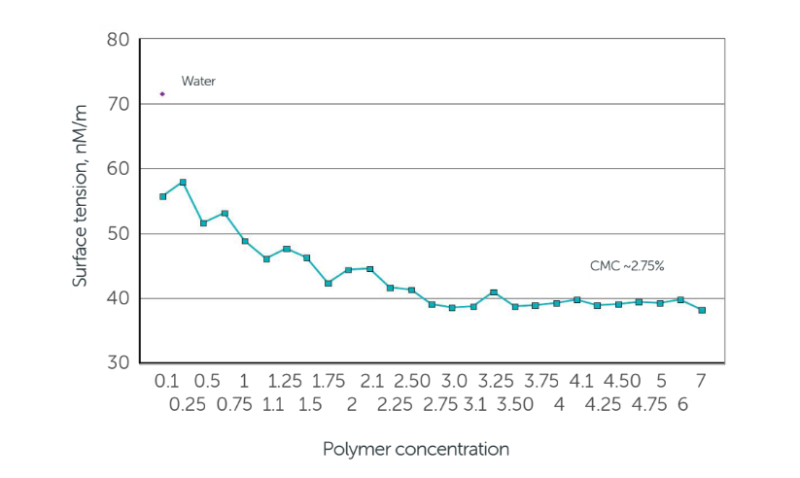

Effects on surface tension

Results of a study to determine the effect of Flexan® II Polymer on surface tension reduction are shown below. The polymer effectively reduces surface tension in water as its concentration increases. Its critical micelle concentration (CMC) is 2.75%. Therefore, the polymer may add cleansing properties to the shampoo. In another study, Flexan® II Polymer was formulated into a mixed ionic surfactant system. Results showed that although the product does not reduce surface tension as strongly as certain surfactants (e.g. alkyl sulfonates), it does not have a negative effect on surfactancy.

Surface tension vs concentration

- Performance in Rinse-off Applications

Removal of cationic build-up

The Flexan II polymer can be used in shampoo formulations to achieve high efficiency removal of cationic buildup, without the use of harsh, irritating surfactants. Traditionally, harsh surfactants have been used in deep cleansing shampoos. The polystyrene units in the Flexan II polymer are 100% substituted with a sulfonate group, which is strongly anionic. Due to its highly anionic properties, Flexan II polymer can complex with cationic buildup to significantly improve the removal of this buildup from anionic surfaces such as hair. The hydrophilic character of the polymer enables it to be rinsed off easily. Thus, Flexan II polymer can improve the cleansing properties of shampoos.The mechanism for cleansing cationic buildup from hair with a system containing Flexan II polymer can be described as follows:

- Hair follicles carry a net anionic charge.

- Many conditioners, styling resins, and surfactants can carry positive charges that allow them to adhere to the anionicbsurface of hair.

- Over time, these cationic products build up on hair.

- The strong negative charge of Flexan II polymer has a greaterbaffinity for the cationic buildup and attracts the cationicbproducts, making it possible to wash away much of the cationic buildup from hair.

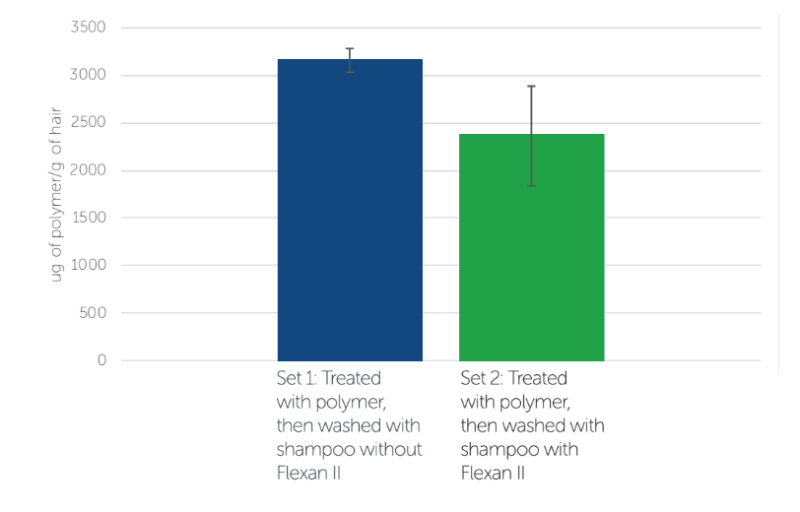

These properties can be particularly useful in mild shampoo systems where the deep cleansing power of mild surfactant systems is improved when combined with Flexan II. In addition, the polymer’s high molecular weight should restrict its ability to penetrate the skin, minimizing its irritation potential, compared to surfactants. Quantitative studies comparing formulated systems with and without Flexan II polymer have demonstrated the effectiveness of the polymer at increasing the removal of cationic buildup. Harsh, stripping surfactants are no longer needed in cleansing systems to remove cationic buildup. A quantitative study using fluorescently labeled Polyquaternium-10, as an example of cationic buildup, shows the impact of the addition of Flexan II polymer to a shampoo made up of mild surfactants. Quantitative analysis of fluorescent polymer removal by shampoos with and without Flexan II polymer indicates a 22% to 25% increase in removal for the shampoo containing Flexan II polymer. Similar removability results are expected for other cationics.

Residual PQ-10 on hair after shampoo treatment

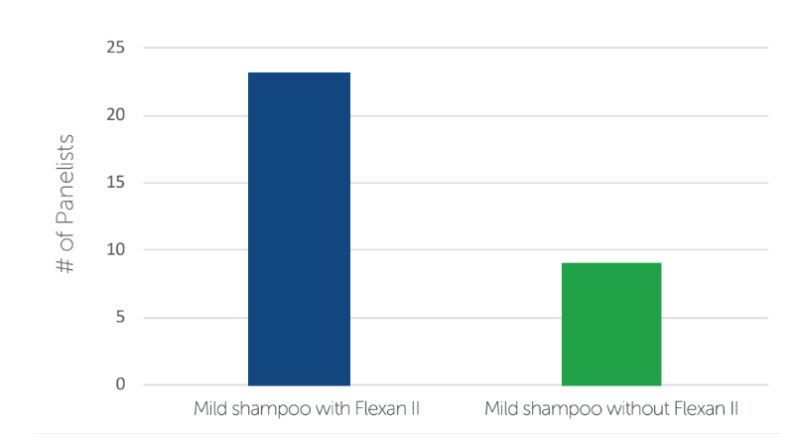

Volumization effects

Another benefit from the removal of cationic buildup by Flexan II polymer is an increase in hair volume or body. Buildup weighs down the hair, causing reduced volume. Hair tresses were treated with Polyquaternium-10 to simulate buildup and were then washed with shampoos with and without Flexan II polymer. Panel test results comparing their volume indicate that Flexan II polymer increases perceived volume of the hair tress. The results below indicate that treatment with the shampoo containing Flexan II polymer provides a significant increase in volume at the 95% confidence level.Value evaluations from 32 Panelists

Performance in skin care applications

For skin care, Flexan II polymer provides a perceptible firming effect on the skin. In applications such as serums, masks, gels, lotions and creams, Flexan II polymer delivers flexible films that contract on drying and give skin tightening properties. Its film forming properties tighten the skin and smooth the fine wrinkles.- Suggested Use Levels

w/w % Hair care, shampoo 1-2% Hair care, styling aid 3-7% Skin care, skin tightening 2-6% Skin care, smoothing wrinkles 2-6%

Properties

- Physical Form

- SDS Physical and Chemical Properties

Value Units Test Method / Conditions Dust Explosion Class St1 - - Dust Deflagration Index 63 m.b/s - Oxidising Properties The substance or mixture is not classified as oxidizing. - - Explosive Properties Not Explosive - - Auto Ignition Temperature (min. 100°C) min. 212 °F - Bulk Density 375 - 500 kg/m³ - Flammability (Solid, Gas) May form combustible dust concentrations in air during processing, handling or other means. - - Partially Soluble in Water - - pH Value (at 30% Concentration) 5.5 - 8.5 - -

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Performance Properties

Hair care performance in leave-on applications.

For hair styling, the film forming Flexan II polymer is truly multifunctional. In styling aids, such as lotions, spritzes, mousses and waxes, Flexan® II Polymer provides flexible styling and manageability without a stiff hold. It forms flexible films so the style is held in place; yet comb and brush easily. After brushing, hair is soft, flexible and fuller with a natural, healthy look.Static Dissipation Conductive Properties

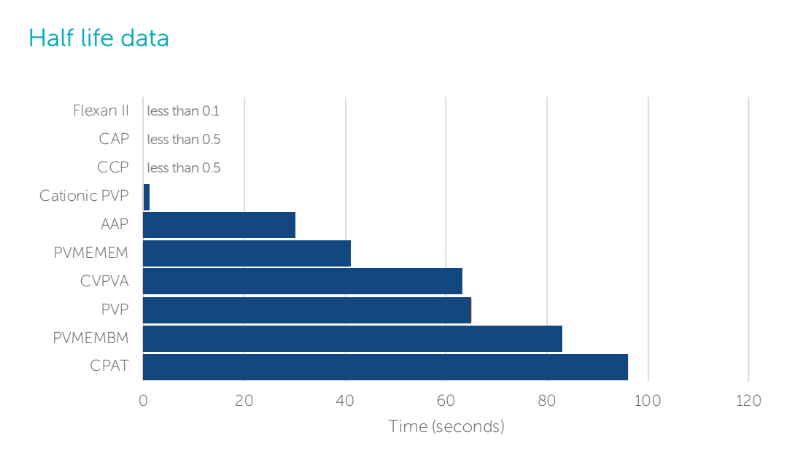

The Flexan® II Polymer has very high charge density and aromaticity, which allows it to quickly dissipate electric charge. Therefore, it can be an effective anti-static agent without imparting stickiness, greasiness or build up problems. It helps prevent flyaway strands allowing for better manageability. When deposited onto hair, the Flexan II polymer dissipates the static charge generated by combing or brushing. The charge dissipation property of the Flexan® II Polymer can easily be verified in the laboratory using a Rothschild Model 1020 Static Voltmeter, which measures half life of an induced voltage across a given substrate. The static dissipation of the Flexan II polymer is equal to or better than that of the other anti-static agents tested. The bar graph shows the half life data (in seconds) for 100 volt DC charge to dissipate to 50 volts across various polymer films conditioned at 50% RH/22°C. Short half-life indicates high conductivity and less potential for static build up on hair.

- CAP = Cationic Acrylic Polymer

- CCP = Cationic Cellulosic Polymer

- AAP = Amphoteric Acrylic Polymer (1)

- PVMEMEM = Poly (vinylmethyl ether/ monoethyl maleate) (2)

- CVPVA = 70:30 Copolymer of vinyl pyrrolidone/ vinyl acetate

- PVP = Polyvinyl Pyrrolidone

- PVMEMBM = Poly (vinyl methyl ether / monobutyl maleate) (2)

- CPAT = Carboxylated polyvinyl acetate terpolymer (1)

- 100% neutralized with 2-amino, 2-methyl, 1-propanol 7% neutralized with monoisopropanolamine

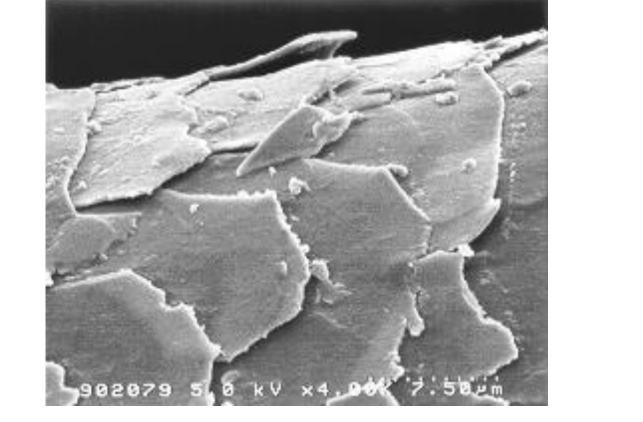

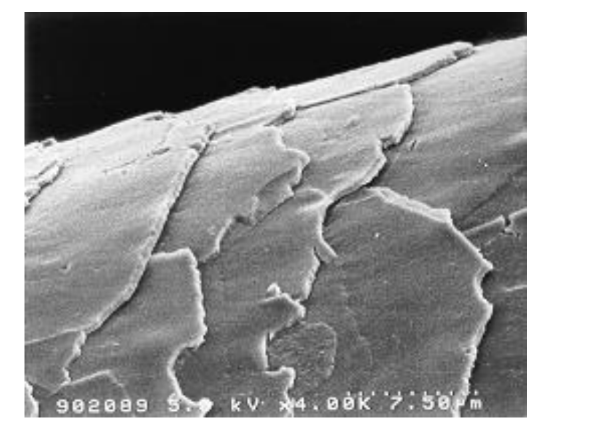

Thermal Protection: SEM studies

When wet hair is dried at room temperature, the cuticle and cortex expand and contract in a synchronous manner. However, when wet hair is heated, rapid water evaporation causes the outer cuticle layer to contract more rapidly than the cortex and lower cuticle layers. As a result, the heat causes outer cuticle cracking and buckling. The cracks and buckles in the cuticle result in weaker hair, which is more susceptible to mechanical damage. Flexan II polymer provides protection from this type of thermal damage. The polymer, when delivered from a leave-on product, forms strong, flexible fims that are thermally stable well above 300°C. High temperatures are reached when using a hair dryer, curling iron, or flat iron during the styling process. SEM pictures have been taken to show the protective benefits the Flexan® II Polymer provides when hair is subjected to heat generated during the styling process. Comparisons were made using a 5% Flexan II polymer solution versus a control solution. The following pictures demonstrate the protective nature of the Flexan II polymer. The damage usually observed to the cuticule from repeated cycles of thermal stresses, such as wetting and styling with heat, is not detected. There is a significant absence of the characteristic thermally induced damages such as: cuticular compression, disintegration of the surface cuticle cell at the fiber/metal interface; radial and axial cracking; and scale edge chipping. In addition, the ever-present bulges or bumps in the scale faces and ripples at the scale edges (formed by moisture trapped in the cuticle) are infrequently observed. It is apparent that damage from the curling iron affects the Flexan II polymer film on the hair instead of the cuticle. It is also believed that the films formed by the Flexan II polymer meter the rate of water evaporation from the top cuticle layer, allowing the cuticles to contract slower. Prevention of rapid water evaporation will protect the hair from the damage caused by thermal treatments. The Flexan II polymer forms smooth, uniform films that cover the fiber surface. These films have small pores or “venting holes”, which are likely due to expansion and escaping of moisture trapped in the wet cuticule under the film. Films formed by the Flexan II polymer also contract upon drying and therefore may have a “shrink wrap” effect where the cuticles are held in place by the film, preventing buckling.

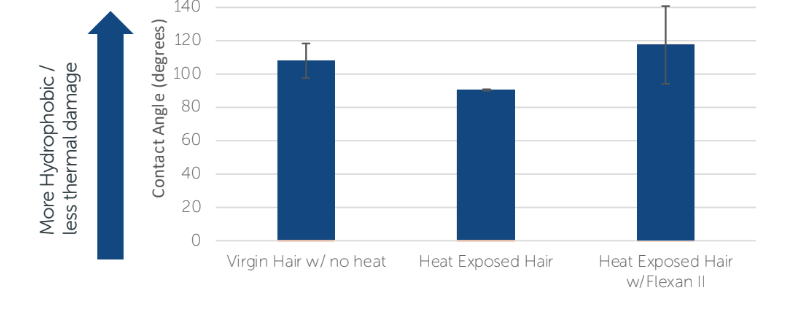

Thermal protection: Dynamic contact angle measurements

Intact, undamaged human hair is very hydrophobic. As hair is damaged, it becomes less hydrophobic. This can be caused by increased porosity from breaking or lifting of the cuticle layer, cracking or splitting or by removal of the lipid layer bound to the hair’s surface. This lipid layer is easily removed, as the bond is fairly weak and can be broken by the heat generated from curling irons and blow dryers. Removal of this lipid layer decreases the hydrophobicity of the hair, an indication of hair damage. Dynamic contact angle measurement can be used to measure the degree of hydrophobicity of human hair. Untreated, undamaged hair is highly hydrophobic and has a contact angle greater than 100°. Conversely, damaged hair is more hydrophilic and has a contact angle near 90°.Hair control at 4,000 magnification after heat treatment

Hair with Flexan® II Polymer 5% solids solution at 4,000 magnification after heat treatment

Hair-liquid dynamic contact angles have been measured using an automated single fiber method (KRUSS: The Process Densitometer and Single Fiber Measuring System K14 manual and J. Apple. Polymer Sic, 29, 1984 and 30, 1985). Virgin, European brown hair fibers were dipped in deionized water for 30 seconds and then dipped into a 5.0% Flexan II polymer solution for another 30 seconds. The fibers were air dried for two minutes and curled using a curling iron for 10 seconds. These steps are repeated for a total of 50 cycles, simulating the extensive hair styling process. Control samples were prepared in the same manner without Flexan II polymer. Data points were gathered in series as a fiber of known size was dipped into a liquid of known density and surface tension. The contact angle between the fiber and liquid was calculated. Hair exposed to heat is damaged; becoming more hydrophilic as evidenced by the reduction in contact angle compared to unexposed hair. Hair treated with Flexan II polymer and exposed to heat does not experience thermal damage. The hair remains hydrophobic and its contact angle is similar to unexposed hair.

Contact Angle/Heat Damage Study

Safety & Health

- Health and Safety

Information on Flexan® II Polymer relating to EU Cosmetics Directive 76/768/EEC is also available upon request. This product may be used in spray applications having a droplet particle size greater than 50 microns. The product has not been properly evaluated for safety clearance for use in pumps and/or aerosols with particle sizes less than 50 microns. The suitability of final formulations should be confirmed in all respects by appropriate evaluation. The marketer is advised to evaluate the final formulation with regard to performance and health safety.

Packaging & Availability

Storage & Handling

- Storage and Handling Information

Flexan II polymer is supplied as an off-white powder. Some settling will occur in the drum during shipping. Flexan II polymer should be stored in a cool, dry location away from heat, sparks or fire. When not in use, the drums should be kept closed to prevent contamination and moisture absorption from the atmosphere. We recommend that normal precautions be taken to avoid ingestion or contact with eyes. Respiratory protection should be used to avoid dust inhalation. Good industrial hygiene practices should be followed. Please read the MSDS before using this or any other chemical.