Enhanced TDS

Identification & Functionality

- Chemical Family

- Manufactured By

- Polymer Name

- CASE Ingredients Functions

- Plastics & Elastomers Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Materials Features

- Additional Information

What is ResNsand Ultra?

ResNsand Ultra (RSU) is a lightweight, optically clear thermoset polymer resin, available in nine standard sizes ranging from 4 mesh (4.76 mm) to 200 mesh (74 micron). RSU is an allyl diglycol carbonate. *Two reactive carbonyl sites on each monomer unit are capable of covalently bonding to a polyamine hardener. The hardener reacts with the epoxy resin matrix, creating a cured final product that is extremely durable and strong. RSU will perform similarly in many other resin systems including polyalcohols and aliphatic or aromatic diisocyanates for polyurethanes, based on a similar mechanism. Polymers without active groups (such as polypropylene) will not possess the same interfacial interactions with the epoxy/hardener system and therefore be less robust/well incorporated.

How tough is a ResNsand Ultra coating?

The increased strength of the RSU coating system is best illustrated when comparing TABER abrasions of clear coat epoxy (control) to a pigmented epoxy. The clear epoxy control showed 0.3 grams abraded after 1,000 cycles using a 500 gram weight versus 0.42 grams abraded for the pigmented epoxy. In general, the addition of a pigment, mineral, or inert non-mineral filler increases abrasion and decreases physical properties of the epoxy polymer. When RSU was added to the clear epoxy control abrasion was reduced to 0.21 grams, a 30% improvement in abrasion resistance. Abrasion was also reduced to 0.21 grams for the pigmented epoxy when RSU was added, a 50% improvement in abrasion resistance.

- Product Features and Benefits

Why use ResNsand Ultra?

- Weight: It can reduce the weight of a coating by 50% over a mineral aggregate.

- Clarity: In a clear coat, RSU will not distort or discolor any patterns or graphics.

- Toughness & Durability: RSU has demonstrated an increase in toughness and durability when used in clear coat epoxies, urethanes, acrylics and polyester gel coats.

- Chemical Resistance: It has excellent chemical resistance to mineral acids, alkalis, aggressive solvents, petroleum spirits, aliphatic and aromatic hydrocarbons and harsh detergents.

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Product Applications

How much ResNsand Ultra is recommended?

How much to use depends on which particle size you select, thickness of film and type of resin being used. The best way to determine your needs is to make a trial run with no more than 100 grams of resin and hardener (if any). Add various weights of RSU (10% is the recommended starting point), mix well and brush onto a flat surface. Compare the results, which based on your judgment gives the desired anti-slip or textured profile.

How is ResNsand Ultra applied?

For large areas such as floors, RSU can either be broadcast or formulated into resin. It can also be applied as a premixed product or mixed on site.

Properties

- Physical Form

- Insoluble in

- Ethanol, Acetone, Non polar solvent

- Typical Physical Properties

Value Units Test Method / Conditions Specific Gravity (H₂0-1) 1.26 - - Melting Point (Decomposes) approx. 400 °F - Particle Size (mech size 40 - 60) 250 - 420 microns - Density 10.9 lb/gal - - Chemical Resistance

Value Units Test Method / Conditions Alcohols Content Excellent - - Aliphatic Hydrocarbons Content Excellent - - Alkali Content Excellent - - Anti Freeze Content Excellent - - Aromatic Hydrocarbons Content Excellent - - Detergents Excellent - - Gasoline Excellent - - Strong and Weak Acids Excellent - - Ketones and Esters* Good to excellent - - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Flash Point 150 °C - pH Value 5.19 - - Relative Density 1.19 - 1.34 - - Appearance Granular clear solid - - Flammability Classification Non-flammable - - Odor Odorless - - Insoluble in Water - - - Note

* - ResNsand will swell in ketone and ester solvents

Regulatory & Compliance

- Chemical Inventories

Technical Details & Test Data

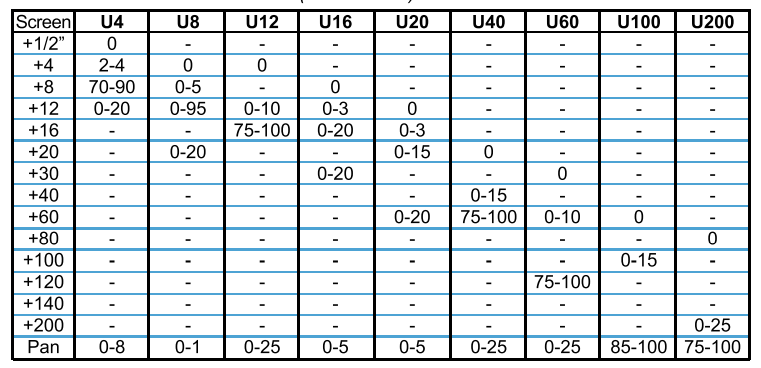

- Typical Particle Distribution