Enhanced TDS

Identification & Functionality

- INCI Name

- Manufactured By

- Cosmetic Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Benefit Claims

- Labeling Claims

- Key Features

- Useful in 55% VOC hair sprays

- Useful in anhydrous, 80%, or 55% VOC hair sprays

- Forms clear, hard flexible films

- Moisture resistant

- Soluble in alcohol and aqueous alkali

- Propellant compatible

- Highly cost efficient

- Compatible with a wide variety of additives

- Excellent set holding of hair

- Excellent subjective properties on hair

Applications & Uses

- Markets

- Applications

- Application Format

- Hair Care Applications

- Use Level

- 2 - 8% (Hair spray)

- Recommended Applications

- Anhydrous, 80% VOC, or 55% VOC aerosol and pump hair sprays

- Styling creams, setting lotions, and spiking glues

- Suggested Use Levels

Application % active Hair spray 2-8% in aerosol formulas, higher concentrations may be used in non-aerosol hair spray formulations - Formulation Guidelines

Solubility

Neutralized Resyn 28-2930 polymer is soluble in anhydrous ethanol and isopropanol. It is insoluble in water but can be made water soluble by complete neutralization of its carboxyl groups with a strong alkali. Suitable neutralizers include AMP (2-amino-2-methyl-1-propanol), ammonium hydroxide, and sodium or potassium hydroxide.

Neutralization

Resyn 28-2930 polymer is carboxylated and must be neutralized in formulating a hair spray. Neutralization level of 80-90% with AMP is suggested for initial evaluation. The final formulation pH of an Resyn 28-2930 polymer containing hairspray should fall within a pH range of 7.5-8.5. The amount of base required to neutralize the carboxyl groups in Resyn 28-2930 polymer can be determined by the following relationship:

Parts by weight (g) of base required=W * A* N * E/1000

Where:

W = parts by weight (g) of Resyn 28-2930 polymer used

A = acidity (meq/g) of Resyn 28-2930 polymer

N = % neutralization required (decimal)

E = equivalent weight of base usedNote:Depending upon the polymer used, it may be necessary in quality control to consider the alkalinity of the polymer in titrations to determine percent neutralization. Contact us for further information and procedures.

Preparation of hair spray concentrates

The preparation of the aerosol concentrates should be carried out according to the procedure outlined in the following example:

- Charge the mixing vessel with the required amount of alcohol

- Start agitation

- Add resin slowly – so that no accumulation of resin occurs on the surface

- After all the resin is added, slowly add the neutralizing agent (if KOH, add as 10% solution in alcohol)*

- Continue mixing until all the resin is in solution

- Add the rest of the ingredients in the formulation

- Filter the concentrate down through 5-10 micron cartridge filters before filling the aerosol containers

* Alcohol temperature dramatically affects solution rate. It is generally suggested that alcohol temperature be 15-20°C. Concentrates of up to 20% neutralized resin in alcohol may be prepared. Care should be taken that the viscosity of the concentrate is suited to the aerosol packing machinery involved.

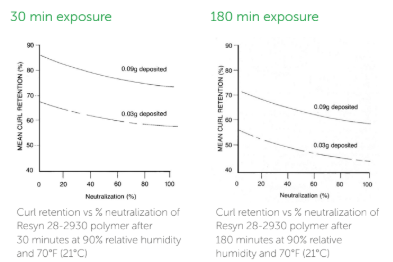

Curl retention

Aerosol hair spray formulations prepared with Resyn 28-2930 polymer have shown excellent resistance to the effects of high humidity. This resistance has been measured in the laboratory by means of a “Curl Retention Test”. In this procedure a 2 gram swatch of human hair is sprayed with the hair spray formulation, formed into a curl, dried and conditioned at 50% R.H. and then exposed in a humidity chamber which is maintained at 90% R.H. and 70°F (21°C). The change in curl length is measured at various time intervals, ranging from 30 to 180 minutes.

Percent curl retention is calculated by the following equation:% curl retention = L - Ltx 100 / L - L0

Where:

L = length of hair fully extended

L0 = length of hair before exposure

Lt = length of hair after exposure for timeBelow the results of such tests are depicted graphically showing the relationship between curl retention and the degree of neutralization with AMP of Resyn 28-2930 polymer at 0.03 g and 0.09 g of resin deposited per hair swatch.

Properties

- Physical Form

- Soluble In

- SDS Physical and Chemical Properties

Value Units Test Method / Conditions Odor Sweet - - Appearance White powder - - Dust Explosion Class St2 - - Oxidising Properties The substance or mixture is not classified as oxidizing. - - Explosive Properties Not Explosive - - Auto Ignition Temperature min. 212 °F - Insoluble in Water - - Bulk Density 825 kg/m³ - Flammability (Solid, Gas) May form combustible dust concentrations in air during processing, handling or other means. - - - Compatibility

Propellants

Resyn 28-2930 polymer is widely used throughout the world in hair sprays. When neutralized with AMP in alcoholic systems it is very compatible with hydrocarbon propellants. Resyn 28- 2930 polymer is very highly compatible with dimethyl ether in many hair spray formulations. Refer to the figure for solubility profile of Resyn 28-2930 polymer in alcohol – water – DME systems.

Two options are available to the formulator to further enhance hydrocarbon compatibility:

- When used as either the primary or secondary neutralizing agent, certain long chain amines are very effective in improving hydrocarbon tolerance of Resyn 28-2930 polymer. Long chain amines can plasticize a polymer and make it water insensitive. For optimum hydrocarbon tolerance and resin stiffness an optimised blend of AMP and long chain amine can be used. Auxiliary plasticizers may not then be needed in the formula. All other properties of the hair spray formulation should then be evaluated.

- Small quantities of water (i.e., 1-15%) in certain aerosol hair spray formulas can also improve hydrocarbon tolerance of Resyn 28-2930 polymer. Refer to the figure for a graphic illustration of the effect of water on Resyn 28-2930 polymer solubility

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Packaging & Availability

Storage & Handling

- Storage and Handling Information

Resyn 28-2930 polymer beads can be stored under ordinary conditions without undergoing decomposition or degradation. When not in use the container should be kept covered to prevent dirt, dust, and moisture pickup. Store in a cool, dry area. Rotate stock.