Enhanced TDS

Identification & Functionality

- INCI Name

- Manufactured By

- Cosmetic Ingredients Functions

- Technologies

- Product Families

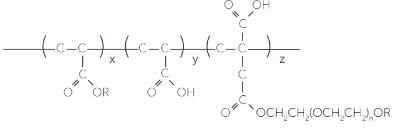

- Chemical Structure

Features & Benefits

- Benefit Claims

- Key Features

low viscosity (as supplied) Easy-to-use aqueous–based emulsion polymers can be readily poured and mixed

Shear-thinning Formulation can be easily squeezed from an applicator, or mixed in a bowl, but will set up readily on the hair

Water soluble when neutralzed With just water, product will easily rinse from the hair

Stable to hydrogen peroxide Structure polymers are excellent choices for inclusion into the hydrogen peroxide containing developer of oxidative hair dyes

Stable viscosity of neutralized systems Structure polymers can also be used in one-component, pre-neutralized formulations such as hair dyes, gels and relaxers.

Synergistic with many common surfactants Viscosity boosts can be achieved through appropriate polymer/surfactant blends

Solvent tolerant At concentrations up to 20%, common solvents will not affect Structure polymer thickening efficiency

Easily neutralized Our thickeners can be neutralized by most commonly-used counter ions

Anionically-charged While use with cationic ingredients is not recommended, Structure polymers are compatible with most non-ionic and anionic ingredients

Applications & Uses

- Markets

- Applications

- Application Format

- Baby Care Applications

- Hair Care Applications

- Skin Care Applications

- Use Level

- 2 - 4 %(Hair dye), 1 - 3 %(Relaxers), 1 - 3 %(Aqueous gels)

- Application Information

Oxidative hair colorants, permanent waves, relaxers, and depilatories have traditionally been thickened by surfactants, fatty alcohols, and waxes. Polymeric thickeners can offer significant advantages in terms of thickening efficiency, ease of manufacturing, and reduction of irritancy while enabling formulators to prepare products that address recent market trends from hydrophobic to more highly aqueous formulations. The Structure® 3001 isthickeners were developed in response to the movement towards highly aqueous formulations. Because these polymeric thickeners are extremely efficient, advantages in terms of minimizing cost while maximizing performance can be achieved. Structure® 3001 thickener is supplied as low viscosity, aqueous emulsions. These pH triggered thickeners are easy-to- handle. For example, in two-component hair dye systems, the polymer can be added directly to the developer where it maintains its low viscosity. This developer can be mixed with an alkaline base. Neutralization will allow the alkali-swellable polymer to effectively and efficiently boost the system viscosity to the formulator’s desired level.Because of differences in monomer composition and ratio, each polymer exhibits a unique set of performance attributes. In addition, blends of the two thickeners can allow a formulator to achieve an optimal balance of properties.Structure thickeners are also well-suited for skin care products, specialty cleansers for the face, body and hair, diaper creams and other difficult-to-thicken formulations.

- Hydrophobic hair color.

- Permanent waves.

- Depilatories

- Product Advantages

Associative polymers offer advantages for hard-to-thicken formulations. Alkalinity triggers the swelling of the Structure® 3001 thickener, but it is the association of pendant hydrophobic monomers which gives the polymers their outstanding efficiency. This association is physical, not chemical, so in the formulation the polymer is highly shear-thinning. This property is critical in many hair care products where the product needs to be easily squeezed from an applicator and massaged into the hair, yet must set up instantly once the shear is removed.

Properties

- Physical Form

- Soluble In

- Typical Properties

Value Units Test Method / Conditions Boil Stability (in 0.1% H₃PO₄) 20 hrs - Boil Stability (in 6% hydrogen peroxide) 20 hrs - H₂0₂ Retained (structure® 3001) 99 - - H₂0₂ Retained (Blank) 100 - - pH Value (at Stability) min. 13 - - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Oxidising Properties The substance or mixture is not classified as oxidizing. - - Explosive Properties Not Explosive - - Dynamic Viscosity max. 1,000 mPa.s - Vapor Pressure (at 20°C) 22.7 hPa - Flammability (Liquids) Not classified as a flammability hazard - - Ignition Temperature min. 100 °C - Flash Point min. 100 °C Closed cup Boiling Point min. 100 °C - Melting Point 0 °C - Soluble in Water - - pH Value 2.2 - 3.5 - - Soluble in Acetone Methanol - - Odor Slight - - Appearance White liquid - - - Formulation Guidelines

While Structure® 3001 polymer thickeners are extremely user- friendly, and in general can simply be added to water, neutralized, and easily mixed, the following guidelines may be helpful. A formulator may want to create an aqueous pre-mix containing about 50% water and 50% polymer as supplied. By no means is this a requirement of using Structure® 3001 polymer thickeners, but it may further reduce processing time and increase processing ease. When using Structure® 3001 polymer in a single-component system, remember to add the neutralizer last. This minimizes mixing energy inputs and allows for more efficient processing. As mentioned earlier, Structure® 3001 polymer can be blended to optimize the performance attributes of both. For example, one might take advantage of Structure® 3001 polymer high efficiency, while blending in the salt tolerance offered by Structure® 3001 polymer. While the choice of monovalent neutralizing agent will have little effect on the thickening efficiency of Structure polymers, we suggest, where possible, to avoid the use of divalent counter ions. When working in high electrolyte formulations, add the thickener first, then add salts.

- Stability Information

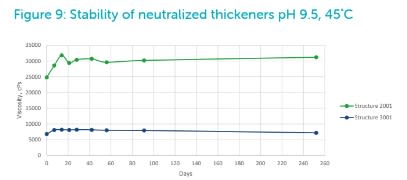

Stability of neutralized thickeners The Structure® 3001 polymer thickeners are stable over time in the presence of heat and high pH. The data below indicates that polymers in the Structure® 3001 polymer series could effectively thicken such one-component hair treatment products as hair gels, semi-permanent colors, and temporary colors. Remarkably, we also see excellent stability at pH >13, and recommend the use of Structure® 3001 polymer in such caustic systems as relaxers and depilatories.

Hydrogen peroxide stability - Structure polymers are stable to hydrogen peroxide over time and in the presence of heat. In standard boil bath tests, nearly all of hydrogen peroxide’s activity was maintained.

UV stability - Acrylic polymers are known to be degraded by UV light. The Structure® 3001 polymer thickeners are no exception. While no viscosity instability is seen at ambient temperatures, a decrease in viscosity is noted in the presence of UV light and high temperature. The use of UV absorbers will prevent this degradation.

Regulatory & Compliance

Packaging & Availability

Storage & Handling

- Storage Information

The Structure® 3001 polymers should be protected from freezing. Avoid extreme temperatures during storage. Good industrial hygiene practices should be followed when working with these polymers.