Enhanced TDS

Identification & Functionality

- INCI Name

- Ingredient Origin

- Manufactured By

- Cosmetic Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Benefit Claims

- Labeling Claims

- Key Features

Features Benefits Cold water-swellable Outstanding dispersability in cold water; improved efficiencies can be achieved in manufacturing and consumer end-use

Nonionic Can be used with cationic conditioning agents. Is also compatible with personal care ingredients common to powdered bleaches, dyes, and emulsions. Tolerates broad pH environments.

Modified waxy maize starch Naturally-derived Biodegradable Improves emulsion stability Allows emulsions to feel richer, creamier, and more substantive

Large particle size Very low dusting compared to typical powdered ingredients

Salt tolerant Remains stable even in the presence of high electrolytes levels

Reconstitutable powders 1%, recommended concentrations depend on dilution factor

Emulsion stability and aesthetics 1% to 3%, significant viscosity effects at concentrations >3%

Applications & Uses

- Markets

- Applications

- Application Format

- Hair Care Applications

- Skin Care Applications

- Use Level

- 1%

- Product Application

- All natural creams

- Lotions

- Powdered bleach

- Powdered hair dyes

Properties

- Physical Form

- Soluble In

- Typical Properties

Value Units Test Method / Conditions Emulsion Stability 1 - 3 % - Dissolution Time 173 secs - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Oxidising Properties The substance or mixture is not classified as oxidizing. - - Explosive Properties Not Explosive - - Dust Deflagration Index 49 m.b/s - Dust Explosion Class St1 - - Flammability (Solid, Gas) Not classified as a flammability hazard - - Ignition Temperature min. 100 °C - pH Value (at 1 % solution) 4.5 - 7 - - Odor Mild - - Appearance White powder - - Soluble in Water - - - Formulation Guidelines

Ease of use - Because Structure ZEA starch is an agglomerated, pre- gelatinized starch, it will dissolve in cold water almost instantly allowing for flexibility in manufacturing and formulation. The mixing of powdered dyes and bleaches with aqueous components is also made much easier for the end user. One can observe the effects of agglomeration (see below) by measuring the dissolution time the of Structure ZEA starch against a non-agglomerated version of the same modified waxy maize starch base.

Starch Dissolution time (sec)

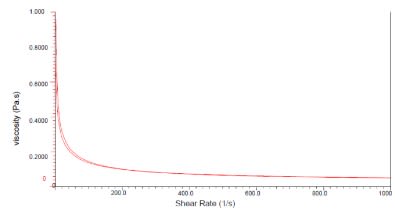

Structure ZEA starch 173 Non-agglomerated Structure ZEA starch 606 Rheology - Structure® Zea starch is extremely shear-thinning, with rapid viscosity recovery. This is an ideal property for hair and skin treatment products where good workability is desired, yet the formulation must set up instantly when shear is removed.Graph below shows a hysteresis loop of a 5% Structure® Zea starch solution. The near overlap of the increasing and decreasing shear sweeps demonstrates the pseudoplastic nature of this rheology modifier. A gap between the two curves would have indicated a longer viscosity recovery time, leaving a formulation prone to dripping when shear is removed.

Hysteresis loop of an aqueous dispersion of 5% Structure® Zea

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Packaging & Availability

Storage & Handling

- Storage Information

Structure® Zea starch should be stored in a cool, dry location away from heat, sparks or fire. Good industrial hygiene practices should be followed when working with this starch.