Enhanced TDS

Identification & Functionality

- INCI Name

- Manufactured By

- Cosmetic Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Benefit Claims

- Key Features

- High hydrocarbon propellant tolerance

- Holds styles under humid conditions

- Gives very firm hold sprays

- High performance acrylate polymer

- Very resistant to humidity

- Forms strong films

Applications & Uses

- Markets

- Applications

- Application Format

- Hair Care Applications

- Use Level

- 1% - 4%

Properties

- Physical Form

- Soluble in

- Ethanol and Isopropanol, Alcohol rich aerosol formula, Water

- SDS Physical and Chemical Properties

Value Units Test Method / Conditions Minimum Ignition Energy 30 - 100 mJ - Explosive Properties Not Explosive - - Dust Deflagration Index 91 m.b/s - Dust Explosion Class St1 - - Bulk Density 500 kg/m³ - Lower Explosion Limit 30 g/m³ - Ignition Temperature min. 100 °C - Insoluble in Water - -

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

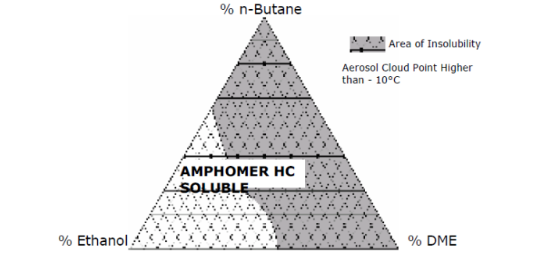

- Solubility of Amphomer HC polymer in ethanol-butane-DME systems

- Amphomer® HC - 3.00

- AMP - 0.73

- Solvent/Propellant - 100.00

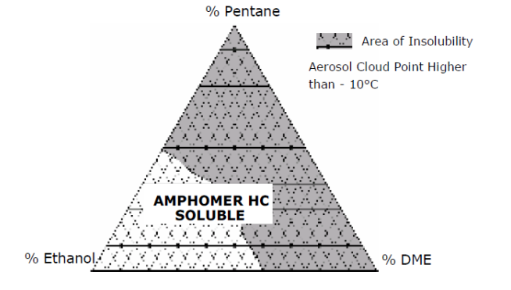

- Solubility of Amphomer HC in ethanol-pentane-DME system

- Amphomer® HC - 3.00

- AMP - 0.73

- Solvent/Propellant - 100.00

- Neautralization

- Amphomer® HC polymer is carboxylated and must be neutralized with a suitable alkaline material for use in hair care formulae. Various neutralizers can be used to achieve a desired effect. The most common neutralizer used is AMP (2-amino-2-methyl-1- propanol). The suggested polymer neutralization level is 90-95%. Under these conditions,Amphomer® HC polymer will accept approximately 50% hydrocarbon in an ethanolic system. Alcoholic KOH can be used for neutralization when higher levels of hydrocarbon tolerance are needed. With KOH, attention should be paid to the formulation stability because of the strength of the base and the high pH of the system.

- The amount of base required to neutralize the carboxyl groups inAmphomer® HC polymer can be determined by the following relationship:

- Parts by Weight (g) of Base Required

W x A x N x E/1000

Where:

W = Parts by weight (grams) ofAmphomer® HC polymer used

A = Acidity of Amphomer HC polymer

E = Equivalent weight of base

N = % Neutralization required (decimal)

Packaging & Availability

- Country Availability