Enhanced TDS

Identification & Functionality

- INCI Name

- Manufactured By

- Cosmetic Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Benefit Claims

- Labeling Claims

- Key Features

- High hydrocarbon propellant tolerance

- Holds styles under humid conditions

- Gives very firm hold sprays

- High performance acrylate polymer

- Very resistant to humidity

- Forms strong films

- Provides additional hold and humidity resistance in styling aids

- Plasticization Benefits

- Amphomer polymer is an exceptionally hard resin which offers the formulator a great deal of freedom in developing hair sprays over a range of tactile properties. In most cases, plasticizers are used in combination with Amphomer polymer to improve feel and to enhance gloss and combing properties.Polymeric “plasticizers” such as Resyn® 28-2930 polymer can also be used to achieve some very interesting results. These can plasticize Amphomer polymer without producing undesirable softening. Propellant compatibility and low temperature stability of any blend should be thoroughly evaluated.

Applications & Uses

- Markets

- Applications

- Application Format

- Hair Care Applications

- Use Level

- 2 - 7%

- Application Information

- Traditional and low VOC aerosol and pump hair sprays, and styling aids such as mousses, gels, creams, pomades, and glues.

Properties

- Physical Form

- Insoluble in

- Water

- Soluble in

- Ethanol and Isopropanol

- Typical Properties

Value Units Test Method / Conditions pH Value 8 - 9 - - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Minimum Ignition Energy 10 - 30 mJ - Explosive Properties Not Explosive - - Dust Deflagration Index 98 m.b/s - Dust Explosion Class St1 - - Bulk Density 500 kg/m³ - Lower Explosion Limit max. 30 g/m³ - Flammability (Solid, Gas) May form combustible dust concentrations in air during processing, handling or other means. - - Ignition Temperature min. 100 °C - Odor Slight - - Color White - - Form Powder - - Insoluble in Water - - - Solubiltiy

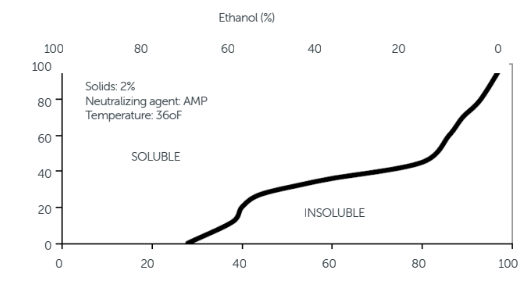

Amphomer polymer is soluble in ethanol and isopropanol. As supplied, it is insoluble in water, but can be made water soluble by complete neutralization of the carboxyl groups with a strong base. Suggested neutralizers include AMP (2-amino-2-methyl- 1-propanol), ammonium hydroxide, sodium hydroxide, and potassium hydroxide. When partially neutralized, Amphomer polymer is soluble in a wide range of water-alcohol blends. Depending on the type of neutralizer used, propellant tolerance needs to be re-checked.

Regulatory & Compliance

Technical Details & Test Data

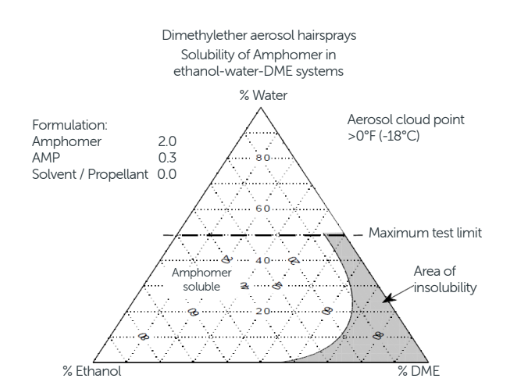

- Solubility of Amphomer in ethanol-water-dme systems

- Neautralization

- Amphomer polymer is carboxylated and must be completely or almost completely neutralized for water solubility and shampoo removability. A neutralization range of 80-100% with AMP is recommended. The final formulation pH of an Amphomer- containing hair spray should fall within a pH range of 8.0-9.0. The level of neutralization can also alter the film properties, where higher neutralization provides a softer, more flexible feel, while lower neutralization imparts a harder, stiffer feel. While AMP is the neutralizing agent of choice, other agents may be used effectively including AMPD (2-amino-2-methyl-1,3-propanediol), monoisopropanolamine, triisopropanolamine, and dimethyl stearamine. The amount of base needed to neutralize the carboxyl groups in Amphomer polymer can be determined by the following relationships:

- B = W * A* N * E/1000

- Where: B = weight of base needed (grams)

- W = weight of Amphomer used

- A = acidity in meq/g of Amphomer

- N = % neutralization required (decimal)

- E = equivalent weight of base

- Organic amines and amino alcohols, when used as neutralizers for carboxylated polymers, will produce a plasticizing effect on the polymer. The degree of softening will be a function of molecular weight and structure of the neutralizer, as well as degree of neutralization required. Neutralization with inorganics provides an excellent way to bring out the inherent stiffness of Amphomer polymer.

- It has been found that certain inorganic neutralizers, such as potassium hydroxide, impart minimal softening while speeding alcohol release from the polymer film. Since inorganic neutralizers are relatively strong bases, the formulator should consider lower percent neutralization of the polymer than would be used with amino alcohol neutralization.

Packaging & Availability

Storage & Handling

- Storage Information

- Amphomer polymer can be stored under ambient conditions without undergoing decomposition or degradation. This product is supplied in fiber containers. When not in use, the container should be kept covered to prevent dirt, dust, and moisture pick-up. Store in a cool, dry area.