Enhanced TDS

Identification & Functionality

- INCI Name

- Manufactured By

- Cosmetic Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Benefit Claims

- Labeling Claims

- Product Benefits

Features Benefits Film-formation Proven water resistance and SPF retention

Resistant to rub-offLow viscosity, polymer emulsion Easy to use

No heat or neutralization required

Exceptional sprayability in spray emulsions

No impact on formulation viscosityBroad acceptability Safety tested for use in spray applications

Globally approved

Applications & Uses

- Markets

- Applications

- Application Format

- Skin Care Applications

- Sun Care Applications

- Use Level

- 1 - 5% active (creams and lotions), 1 - 20% active (color cosmetics), 1 - 5% active (tinted sunscreens), 1 - 3% active (spf daily wear moisturizer), 2 - 5% active (sun protection)

- Recommended Applications

- Daily wear moisturizers with SPF

- Recreational sun protection products

- Tinted sun protection products

- Color cosmetics

- Face, body and hand creams and lotions

- Formulation Guidelines

- Supplied as a liquid aqueous emulsion, Dermacryl® AQF polymer is easily dispersed in the water phase of oil-in- water emulsions.

- Dermacryl® AQF polymer can either be added into the water phase prior to forming the emulsion or post added after the emulsion is formed.

- It requires no heat or neutralization and can be used in either hot or cold emulsification processes.

- The material can be used at typical sunscreen formulation pH ranging from pH 5 to 7.

- Spray emulsions

- Although Dermacryl® AQF polymer can be used in a broad range of sunscreen emulsions, it is particularly well suited for sunscreen spray emulsions.

- The polymer does not increase formulation viscosity which allows the formulator to create water resistant spray emulsion sunscreens with excellent spray aesthetics.

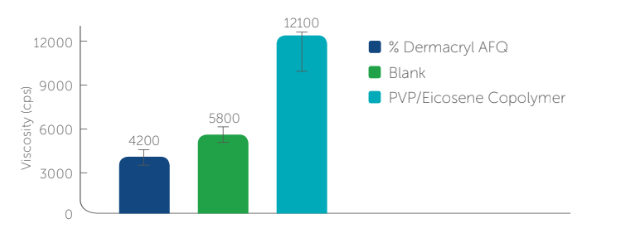

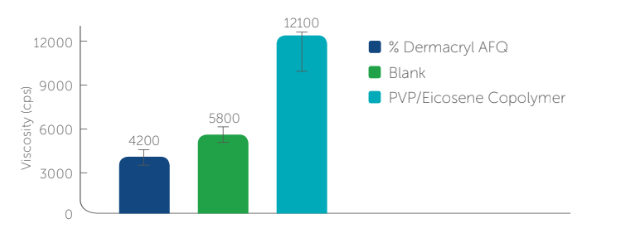

- A spray system was formulated to demonstrate the impact of film forming polymers on formulation viscosity and spray performance as shown below.

- The system containing Dermacryl® AQF polymer was less viscous than a similar systems formulated with PVP/Eicosene Copolymer.

- Viscosity benefit on spray formulation

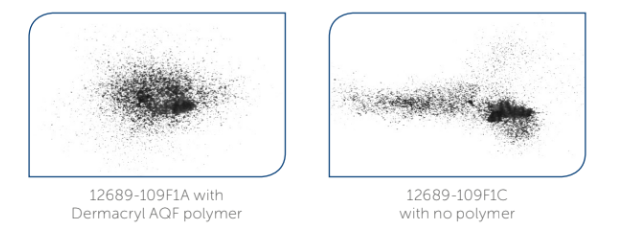

- Spray characteristics

- The spray pattern on the left is for an emulsion formulated with Dermacryl® AQF polymer and on the right is the same emulsion formulated with PVP/Eicosene copolymer.

- Dermacryl® AQF on the left has excellent spray aesthetics including less particle drift which results in more uniform coverage.

- Performance Properties

In-vivo SPF evaluation:

- Dermacryl® AQF polymer provides the ability to create water resistant sunscreen emulsions.

- The polymer exhibits excellent SPF retention after immersion in water in both in-vitro and in-vivo testing.

- The sunscreen emulsion systems were evaluated by Florida Suncare Testing, Inc. SOPs #2011-04, 2011-01, Static and 80 Minute Water Resistant SPF Testing as set forth by the FDA, 21 CFR Sec. 201.327, subpart (i), SPF Test Procedure, Sunscreen Drug Products for Over-the-Counter Human Use, Final Monograph, Federal Register, Vol. 76, No. 117, June 17, 2011. Two similar sunscreen formulations were compared for their ability to retain SPF after 80 minute immersion in water.

- These formulations vary in their use level of the film former.

Results:

- Formulas with both 1% and 2% active Dermacryl® AQF polymer tested as 80 min very water resistant in SPF 50 target systems.

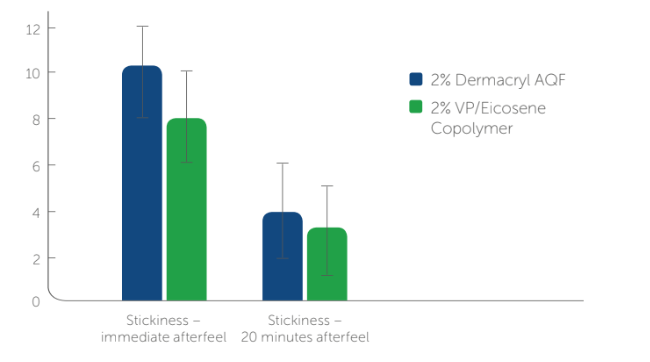

Sensory evaluation:

- The sensory evaluation was performed by expert panelists trained in Skinfeel Descriptive Analysis methodology.

Results:

- Dermacryl® AQF polymer was shown to have statistically similar tack as compared to VP/Eicosene Copolymer at both immediate and 20 minute afterfeel timepoints.

- Testing was performed at Sensory Spectrum.

- Skinfeel analysis

Properties

- Physical Form

- SDS Physical and Chemical Properties

Value Units Test Method / Conditions Oxidising Properties The substance or mixture is not classified as oxidizing. - - Explosive Properties Not Explosive - - Dynamic Viscosity max. 500 mPa.s - Auto Ignition Temperature min. 212 °F - Soluble In Water - - Relative Vapor Density (Air = 1) 0.62 - - Vapor Pressure (at 68°F) 23.3 hPa - Flammability (Liquids) Not classified as a flammability hazard - - Evaporation Rate 1 - - Flash Point 212 - 390 °F - Boiling Point min. 212 °F - Melting Point 32 °F - pH Value 2 - 4 - - Odor Slight - - Appearance White powder - - - Compatibility

Sunscreen actives:

- Dermacryl® AQF polymer performs well in the typical sunscreen formulation pH range, pH 4 to 8.

- It has excellent compatibility with commonly used sunscreen actives, including Ethylhexyl Methoxycinnamate (Octinoxate), Ethylhexyl Salicylate (Octisalate), Benzophenone-3 (Oxybenzone), Homosalate, Octocrylene, Avobenzone, and Zinc Oxide.

- Dermacryl® AQF polymer is sensitive to some coatings in Titanium Dioxide (TiO₂) dispersions.

- The following grades of titanium dioxide dispersions have good compatibility with the polymer and can be used as starting points when formulating TiO₂ containing sunscreens with Dermacryl AQF polymer.

- Dermacryl® AQF polymer performs well in the typical sunscreen formulation pH range, pH 4 to 8.

- It has excellent compatibility with commonly used sunscreen actives, including Ethylhexyl Methoxycinnamate (Octinoxate), Ethylhexyl Salicylate (Octisalate), Benzophenone-3 (Oxybenzone), Homosalate, Octocrylene, Avobenzone, and Zinc Oxide.

- Dermacryl® AQF polymer is sensitive to some coatings in Titanium Dioxide (TiO₂) dispersions.

- The following grades of titanium dioxide dispersions have good compatibility with the polymer and can be used as starting points when formulating TiO₂ containing sunscreens with Dermacryl® AQF polymer.

Pigment coatings:

- Dermacryl® AQF polymer shows good compatibility with commonly used pigment coatings.

- These pigments were tested at a 10% use level in a screening emulsion containing Ethylhexyl Methoxycinnamate and included pigments coated with the following:

- Dimethicone Copolyol, Triethoxy Caprylylsilane, Triethoxyl Caprylylsilane, Isopropyl Titanium Triisostearate, Perfluoroalcohol Phosphate, bonded Dimethylpolysiloxane, Disodium Steroyl Glutamate.

Salts:

- For formulations containing electrolytes, (i.e. water in oil or water in silicone emulsions), Dermacryl® AQF polymer has good salt tolerance.

- The polymer (4% active tested) can tolerate up to 1% and 2% of magnesium sulfate and sodium chloride, respectively, as well as any level of sodium citrate (maximum salt level tested: 4% by weight).

- For formulations containing electrolytes, (i.e. water in oil or water in silicone emulsions), Dermacryl® AQF polymer has good salt tolerance.

- The polymer (4% active tested) can tolerate up to 1% and 2% of magnesium sulfate and sodium chloride, respectively, as well as any level of sodium citrate (maximum salt level tested: 4% by weight).

Other:

- Dermacryl® AQF polymer is also compatible with a wide range of commonly used cosmetic ingredients: Carbomer, XanthanGum, Acrylates/C12-30 Alkyl Acrylate Crosspolymer, and other frequently used thickeners and emulsifiers.

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Packaging & Availability

Storage & Handling

- Shelf Life

- 12 months

- Storage Information

- Dermacryl® AQF polymer should be protected from freezing. Avoid extreme temperatures during storage. Good industrial hygiene practices should be followed when working with this polymer. This product is best used within 12 months of manufacture.